Aluminum-titanium-boron-strontium-rare earth alloy wire rod and preparation method

A rare earth alloy, aluminum titanium boron technology, applied in the field of aluminum alloy, can solve the problems of insufficient deterioration of the casting billet, linear stripe defects, alloy surface defects, etc., and achieve the effects of better distribution, uniform distribution and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1 A kind of preparation method of aluminum-titanium-boron-strontium-rare earth alloy wire rod

[0035] An aluminum-titanium-boron-strontium-rare earth alloy wire rod, the weight ratio of its components is: metal aluminum: potassium fluorotitanate: potassium fluoroborate: lanthanum cerium mixed rare earth: metal strontium = 100:25:12:5:5 ; Composition by weight percentage in lanthanum-cerium mixed rare earth: lanthanum 35%, cerium 65%.

[0036] The preparation method of the aluminum-titanium-boron-strontium-rare earth alloy wire rod comprises the following steps:

[0037] (1) Put 5000kg of aluminum ingot into the melting furnace to melt, then discharge 2000kg of molten aluminum into the electromagnetic induction furnace and heat to 750°C for later use;

[0038] (2) After fully mixing 500kg of potassium fluotitanate and 240kg of potassium fluoborate, add it into the molten aluminum while stirring, and continue to mechanically stir for 10 minutes after the addi...

Embodiment 2

[0046] Performance analysis and application test of embodiment 2 products of the present invention

[0047] 1. Metallographic analysis

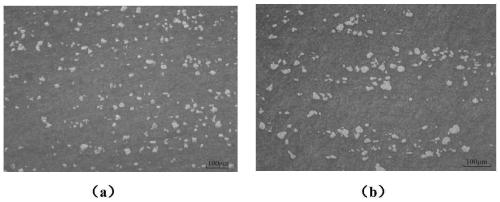

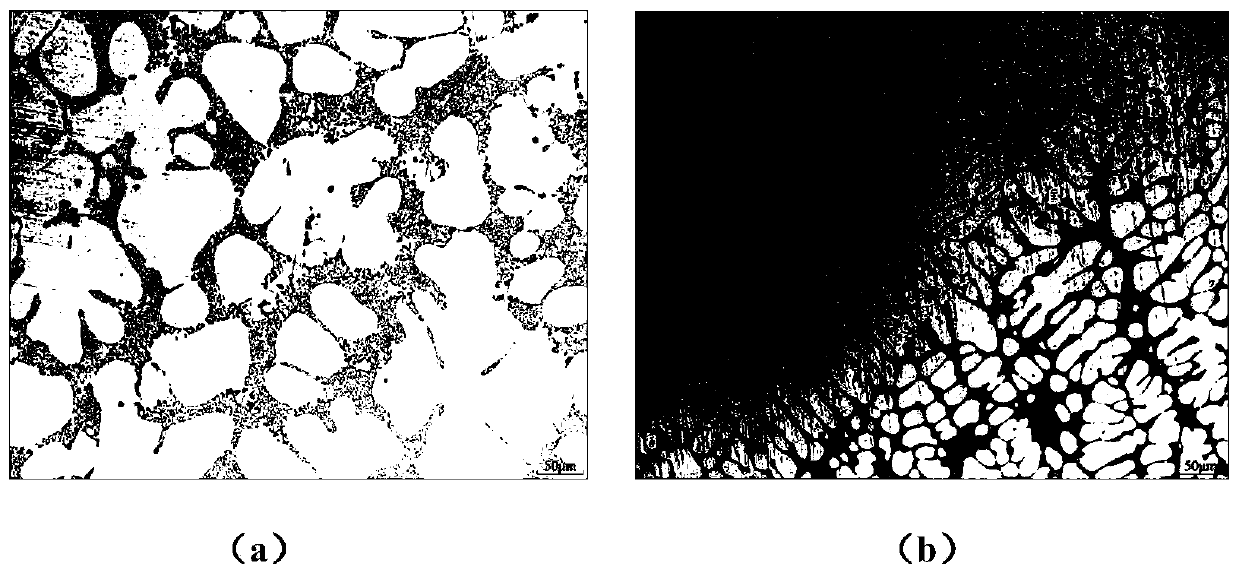

[0048] Compare the metallographic pictures of the product of the present invention and the existing AlTi5B1 aluminum alloy product, as figure 1 shown.

[0049] The results show that the present invention adds rare earth elements in the alloy wire, so that TiAl in the modified and refined material 3 Size reduction, TiB 2 The distribution is more uniform and dispersed, which greatly improves the refining effect of the product and prolongs the refining time. Ti in the alloy wire during use 2 al 20 RE particles can quickly dissolve and release rare earth elements in molten aluminum, increasing the viscosity of molten aluminum and nucleating particles TiB 2 The surface activity of , promotes fast nucleation and hinders TiB 2 Coagulation and precipitation, so as to achieve better refinement effect.

[0050] By studying the influence of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com