Deep water surface casing running tool relief simulating experimental device and method

A technology for simulating an experimental device and a feeding tool, which is applied in the field of a deep water surface catheter feeding tool release simulation experimental device, can solve problems such as inability to be accurately and effectively released, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 provides a deep-water surface conduit running tool release simulation experiment device, the structure of which will be described in detail below.

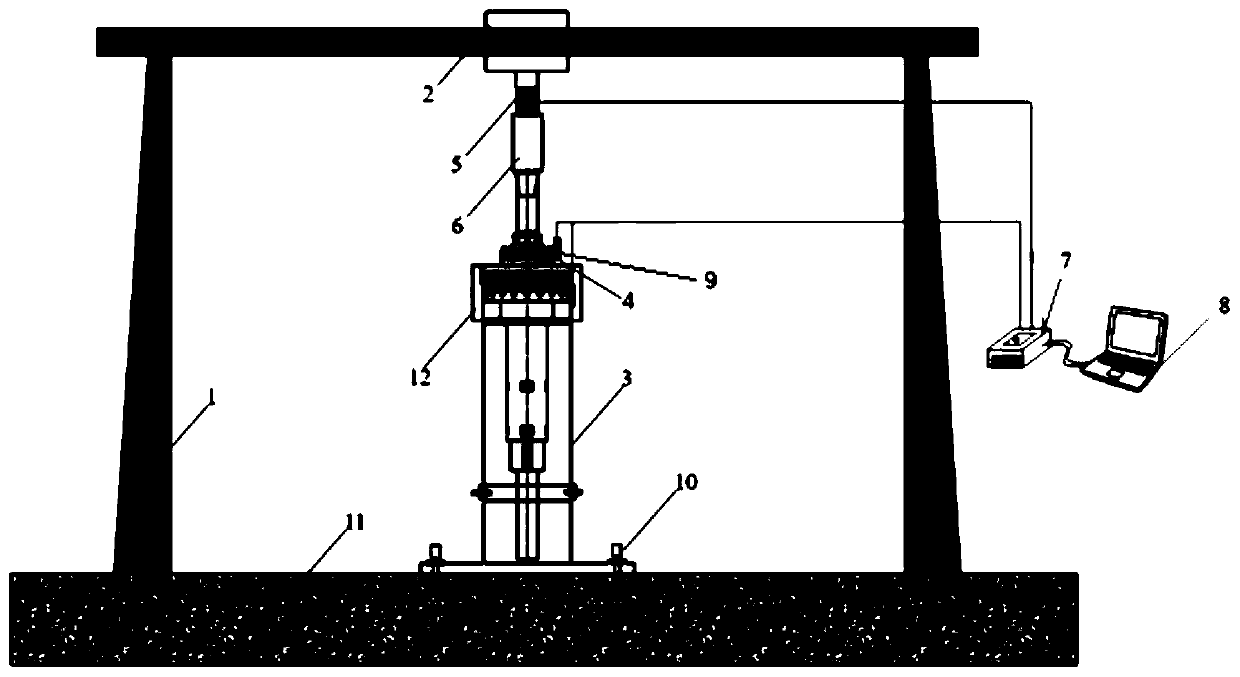

[0033] refer to figure 1 , the deep-water surface conduit feeding tool release simulation experiment device includes an experiment frame 1, a low-pressure wellhead head 3, a deep-water surface conduit feeding tool 4, a rotating motor 2, a lifting motor device, a coupling 6, a data collector 7 and a computer 8 .

[0034] The bottom of the test frame 1 is provided with a base 11, specifically, the base 11 is a reinforced concrete structure base. The low-pressure wellhead head 3 is fixed on the base 11 by fastening bolts 10 .

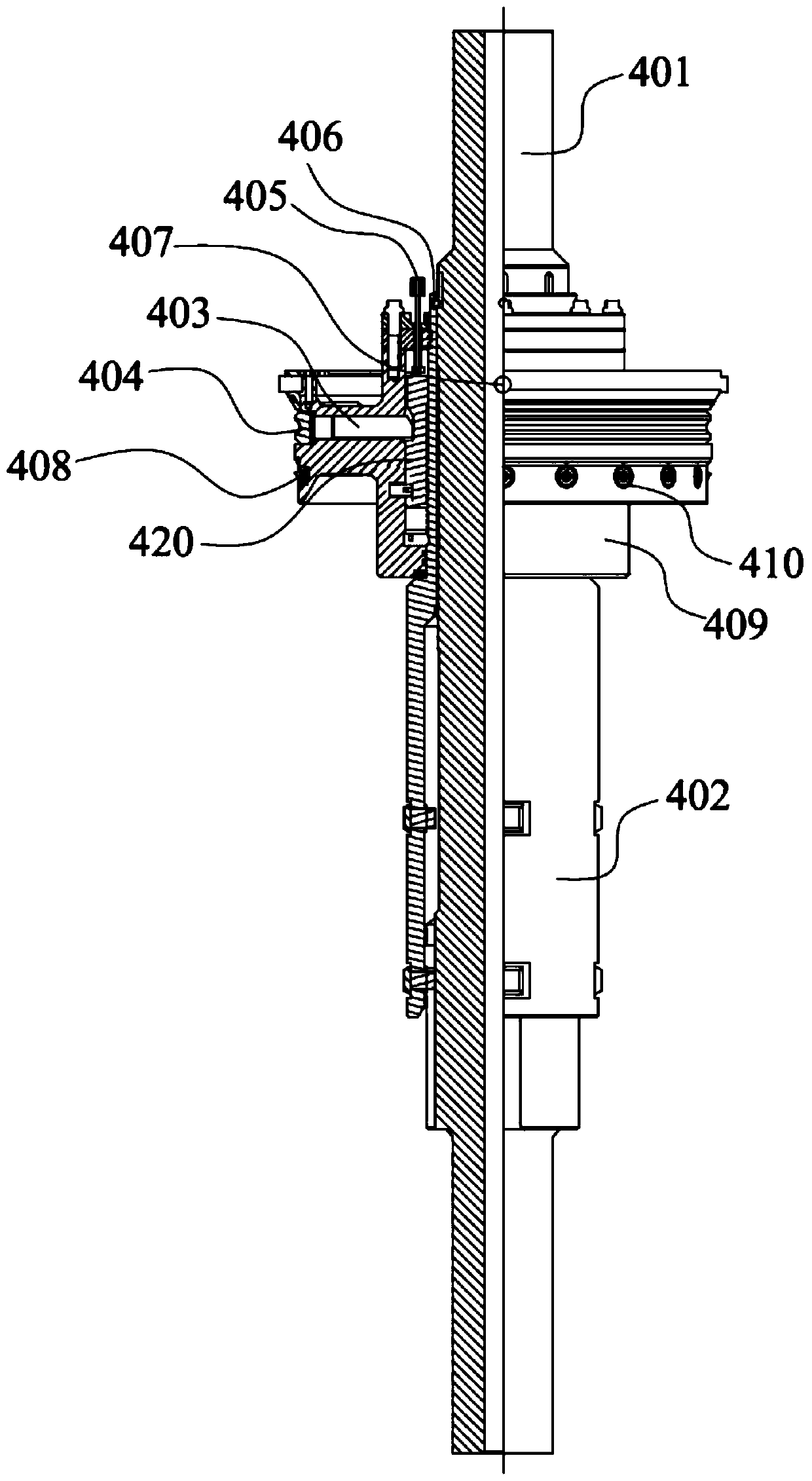

[0035] The upper part of the low-pressure wellhead head 3 is a deep-water low-pressure wellhead head, which is provided with two bosses, and the lower part of the deep-water surface conduit feeding tool 4 is provided with two flanges. The flanges at the bottom of the 4 are matched, and t...

Embodiment 2

[0063] Embodiment 2 provides a kind of deep-water surface layer conduit into tool release simulation experiment method, adopts the deep-water surface layer conduit into tool release simulation experiment device that embodiment 1 provides, and this release simulation experiment method comprises the following steps:

[0064] Step S1: Cut off the release pin 406, and separate the mandrel 401 and the bushing 402;

[0065] Step S11: Install the rotating motor 2 on the horizontal plate of the test frame 1, and connect the mandrel 401 of the deep-water surface conduit feeding tool 4 to the output shaft of the rotating motor 2 through the coupling 6;

[0066] Step S12: start the rotating motor 2, rotate the mandrel 401 clockwise until the release pin 406 is cut off, the mandrel 401 is separated from the bushing 402, and the mandrel 401 is rotated and moved down;

[0067] Step S2: Cut off the positioning pin 408 and the anti-rotation pin 407;

[0068] Step S21: Set the lifting motor d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com