Arc welding power supply for welding pipeline

A technology of arc welding power supply and pipeline, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve problems such as unsatisfactory, large volume, affecting welding speed and quality product cost performance, etc., to achieve volume reduction and weight reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

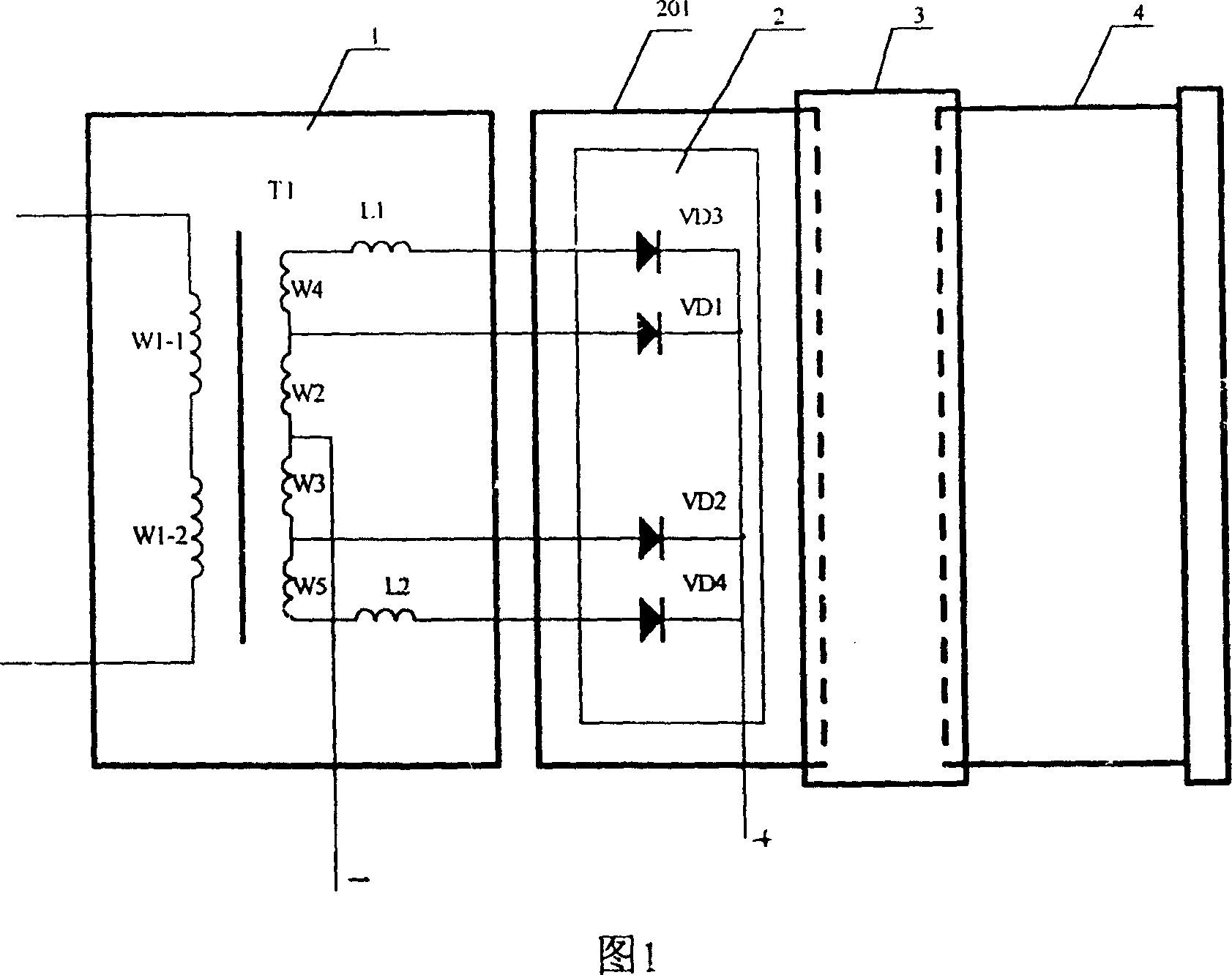

[0014] The structure shown in Figures 1 and 2.

[0015] The primary of the output transformer 1 consists of a winding W 1-1 , W 1-2 constituted, the secondary consists of two main windings W 2 , W 3 and two secondary windings W 4 , W 5 constitute. The four windings of the secondary W 2 , W 3 , W 4 , W 5 Respectively with the four rectifier tubes V in rectifier 2 D1 , V D2 , V D3 , V D4 connected. In both secondary windings W 4 , W 5 with two rectifiers V D3 , V D4 The current-limiting inductance L is connected in series respectively 1 , L 2 .

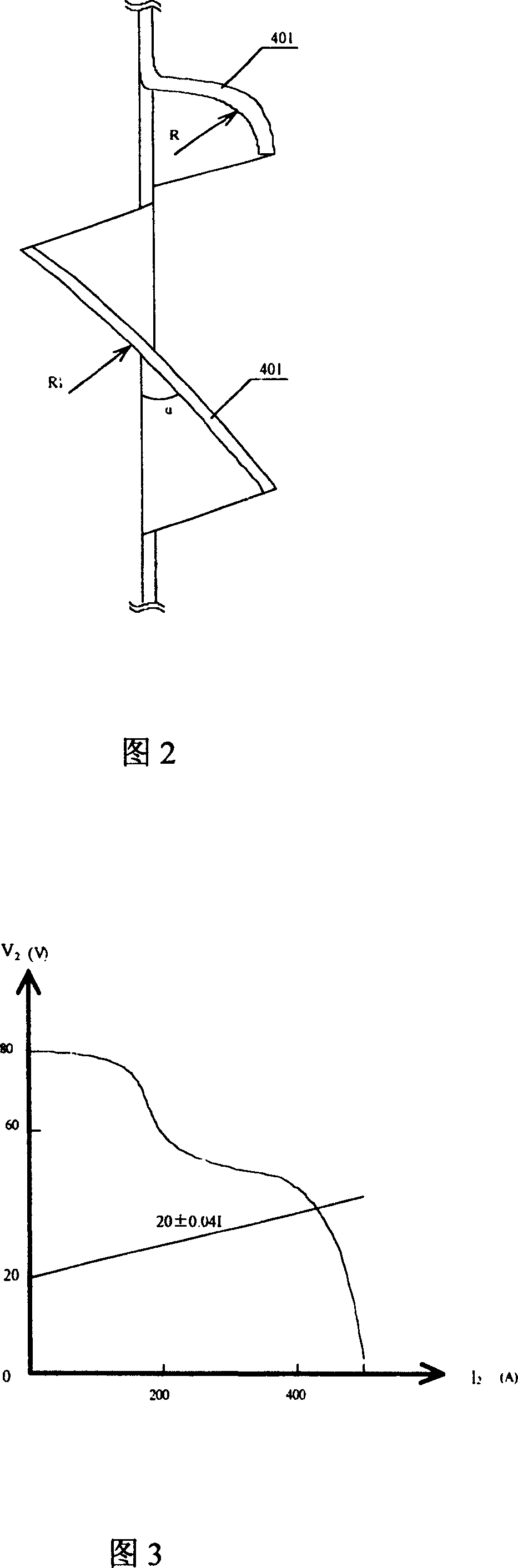

[0016] Said rain-proof ventilation louver forming cooling device 4 is formed by the continuous stamping and forming of thin steel plate. Its blades 401 form an inclination angle of α=45°, and the section of the blades 401 is arc-shaped R. The window surface of the louver covers the heat dissipation surfaces of all rectifiers 2 radiators 201 . as shown in picture 2.

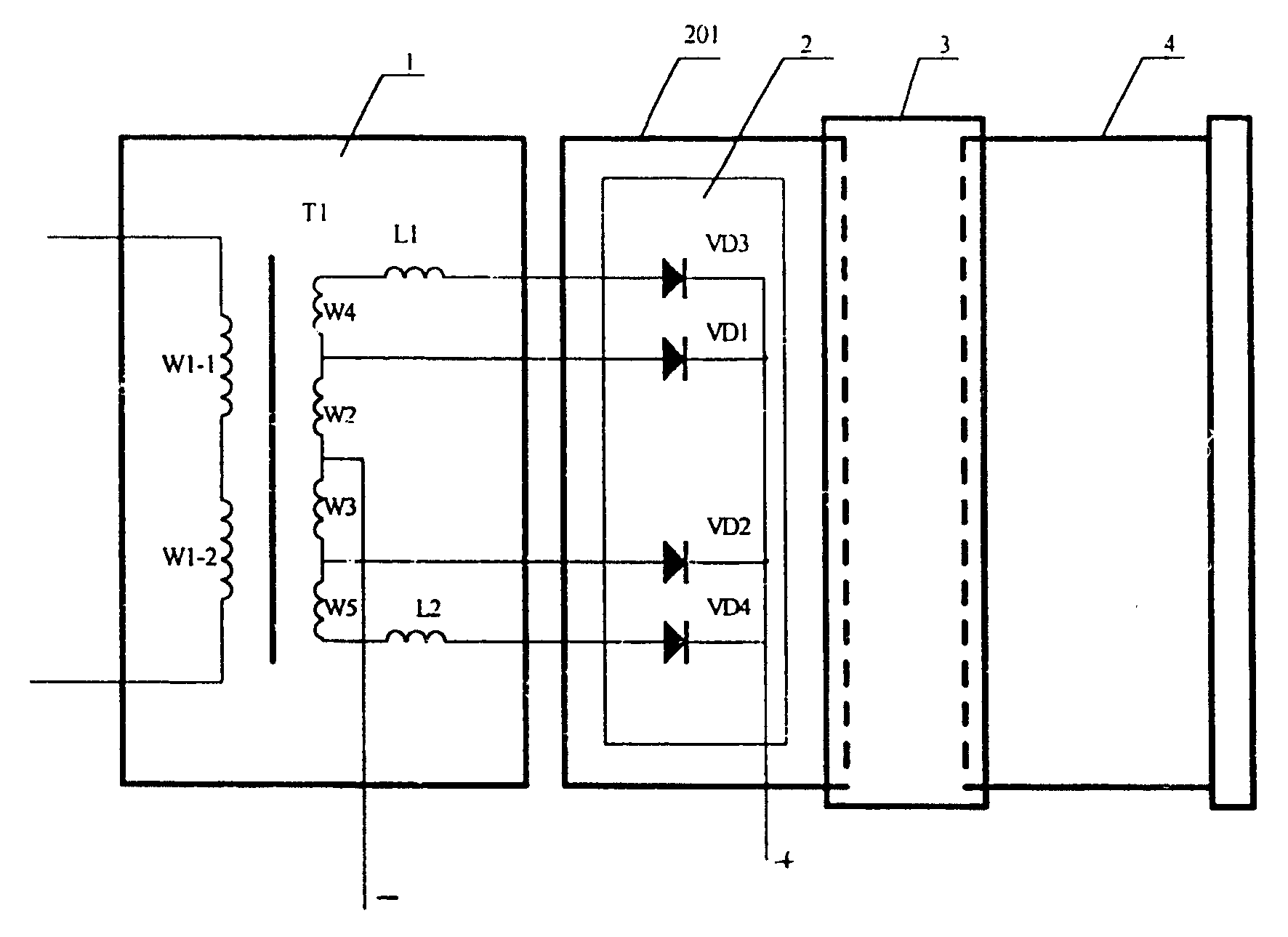

[0017] The V-I characteristic curve obtained b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com