Medicine eluting instrument and manufacturing method thereof

A drug and device technology, applied in the field of drug-eluting devices and its manufacturing, can solve the problems of inability to play a therapeutic role, increase the risk of thrombus, and match the repair process of drug lesions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

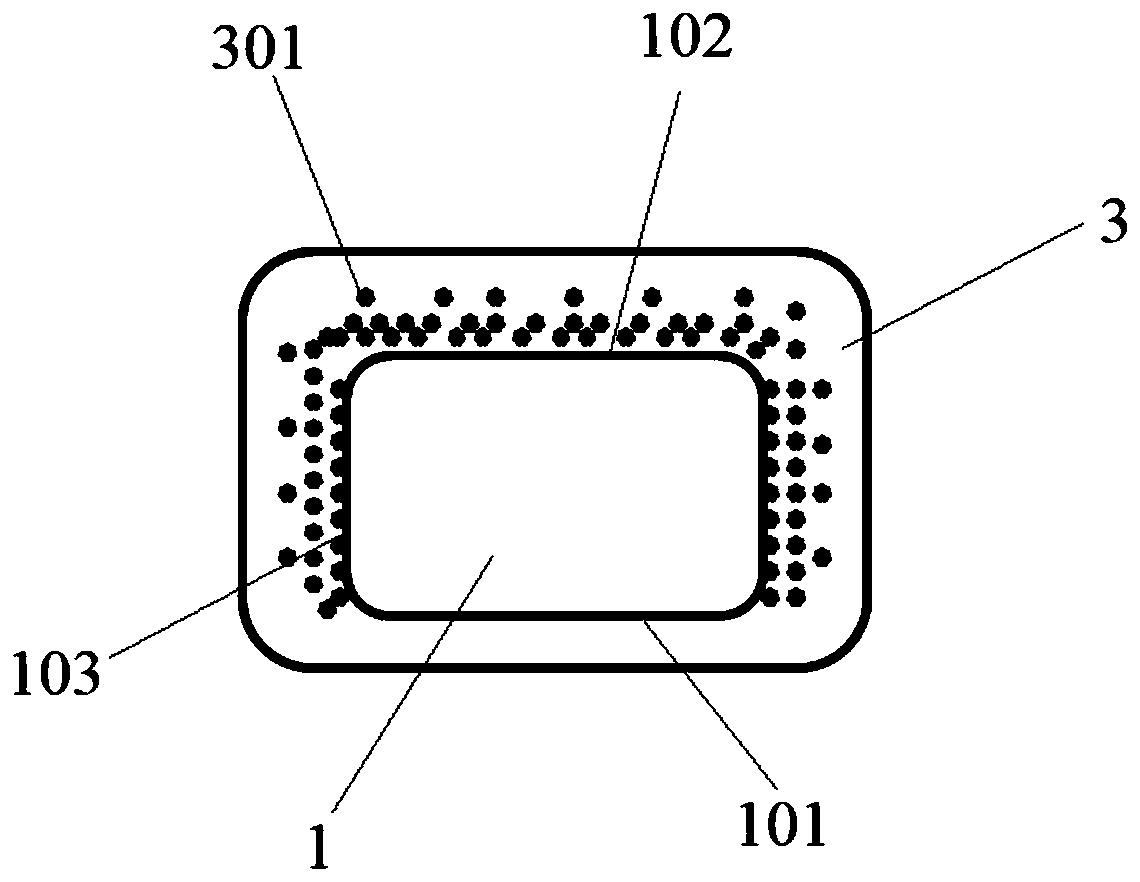

Embodiment 1

[0085] First prepare the ethyl acetate solution of rapamycin with a concentration of 5 mg / mL and the ethyl acetate solution of poly(racemic lactic acid) with a concentration of 3 mg / mL; prepare a matrix formed of pure iron with a specification of 30008, and wrap the matrix with On the inner struts, the base is slightly compressed so that the inner surface of the base is pressed against the inner struts. Then spray the ethyl acetate solution of rapamycin on the substrate by ultrasonic spraying, remove the inner strut after drying to obtain a stent containing a pure drug layer, wherein the pure drug layer completely covers the outer surface and side surface of the substrate; Spray the ethyl acetate solution of polyracemic lactic acid onto the inner surface, outer surface and side surface of the stent, the coating speed of this step is 0.03mL / min, the ethyl acetate in the ethyl acetate solution of polyracemic lactic acid Dissolve all the rapamycin in the pure drug layer into the ...

Embodiment 2

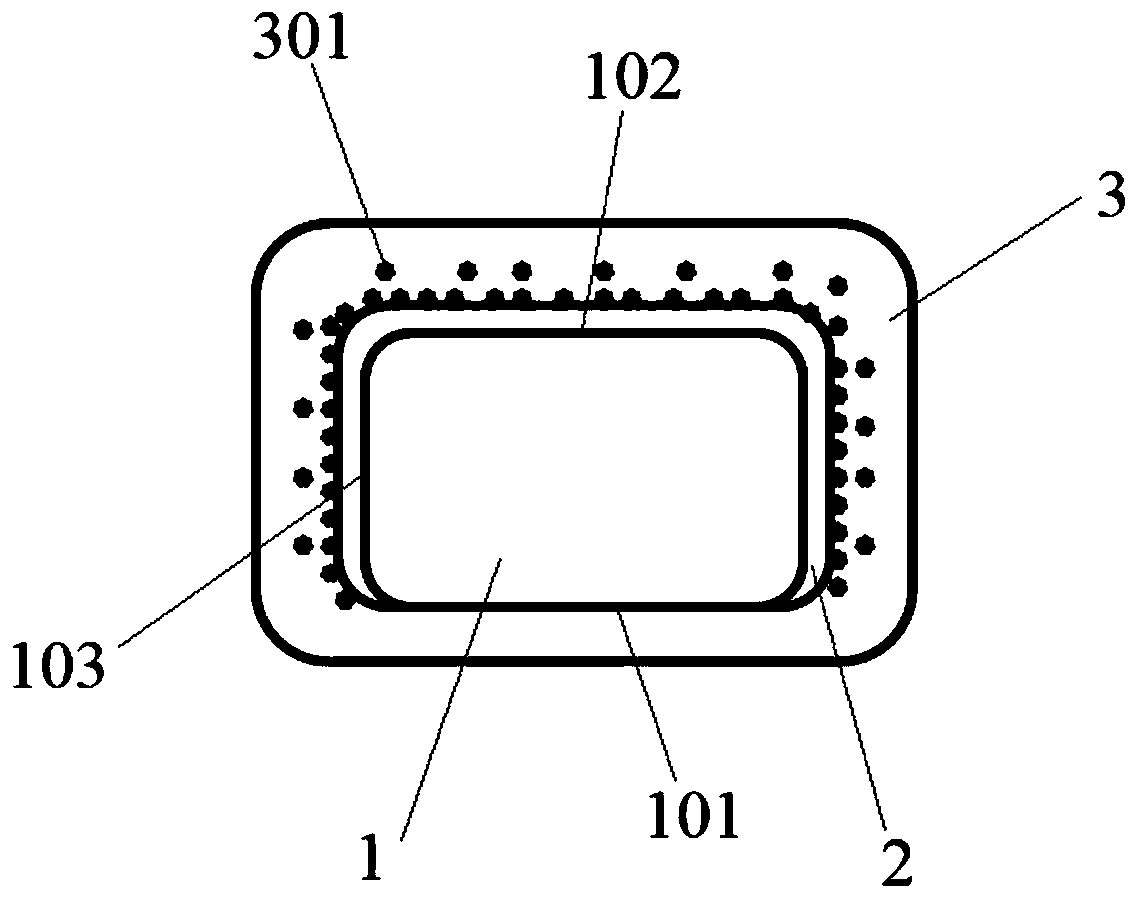

[0088] First prepare the ethyl acetate solution of rapamycin with a concentration of 5 mg / mL and the ethyl acetate solution of poly(racemic lactic acid) with a concentration of 10 mg / mL; prepare a matrix formed of pure iron with a specification of 30008, and cover the matrix with On the inner struts, the base is slightly compressed so that the inner surface of the base is pressed against the inner struts. Then spray the ethyl acetate solution of rapamycin on the substrate by ultrasonic spraying, remove the inner strut after drying to obtain a stent containing a pure drug layer, wherein the pure drug layer completely covers the outer surface and side surface of the substrate; Spray the ethyl acetate solution of polyracemic lactic acid onto the inner surface, outer surface and side surface of the stent, the coating speed of this step is 0.10mL / min, the ethyl acetate in the ethyl acetate solution of polyracemic lactic acid The rapamycin in the pure drug layer is partially dissolv...

Embodiment 3

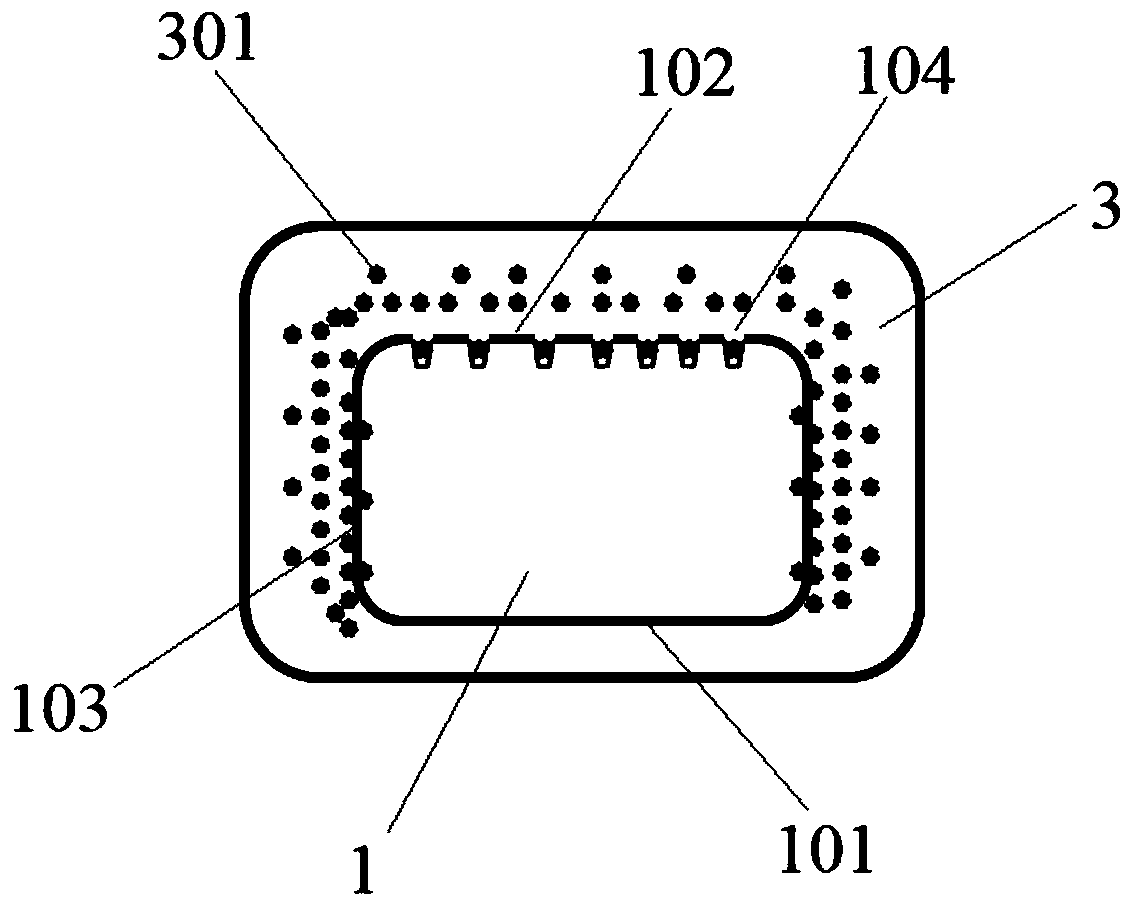

[0091]First prepare the ethyl acetate solution of rapamycin with a concentration of 5 mg / mL and the ethyl acetate solution of poly(racemic lactic acid) with a concentration of 10 mg / mL; prepare a matrix formed of pure iron with a specification of 30008, and the surface of the matrix is treated with For roughening treatment, grooves are formed on the substrate, and the plane where the opening end of the groove is located is coplanar with the outer surface of the substrate. The substrate is placed on the inner strut, and the substrate is slightly compressed so that the inner surface of the substrate is close to the inner strut. Then spray the ethyl acetate solution of rapamycin on the substrate by ultrasonic spraying, remove the inner strut after drying to obtain a stent containing a pure drug layer, and the groove of the substrate is filled with rapamycin, the pure drug layer Completely cover the outer surface and side surface of the matrix; then spray the ethyl acetate soluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com