Shaking type machine tool cooling liquid efficient production equipment

A technology for production equipment and cooling liquid, applied in the directions of shaking/oscillating/vibrating mixers, mixers, dissolving, etc., can solve the problems of low mixing efficiency, poor lubrication performance, poor finished product effect, etc., to improve mixing efficiency and uniformity. performance, ensuring mixing efficiency and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

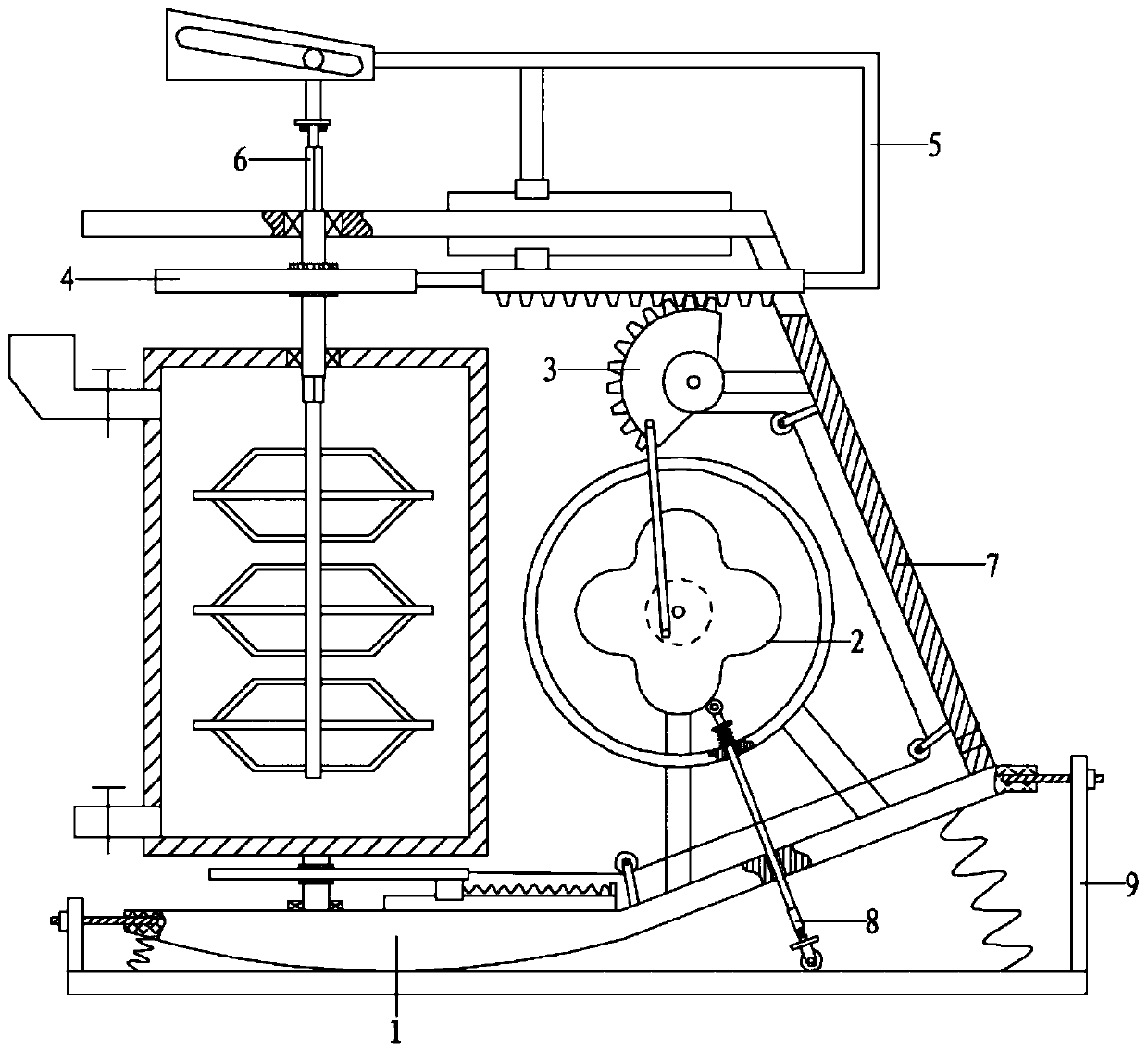

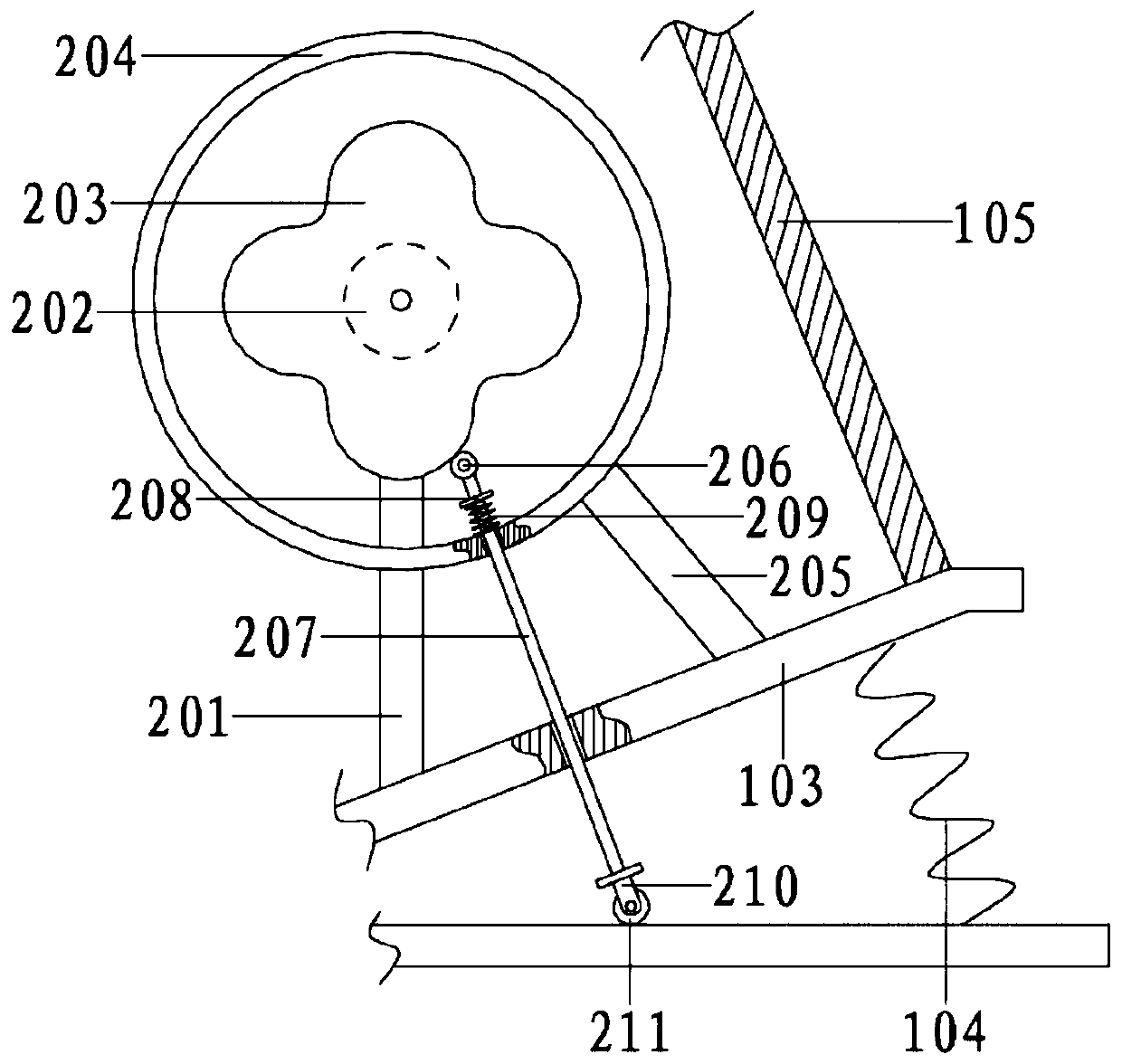

[0062] Referring to the accompanying drawings, a high-efficiency production equipment for swaying machine tool coolant includes a frame assembly 1, a sway assembly 2, a transmission assembly 3 and a mixing assembly 4;

[0063] The frame assembly 1 includes a bottom plate 101, a shaking seat 102, a support plate 103, a return spring 104, a side plate 105, a top plate 106 and a mixing tank 107; Connect with back-moving spring 104; The bottom of rocking seat 102 is an arc surface, and overlaps with base plate 101; Rocking seat 102 right end is connected with support plate 103, also is connected with return spring 104 between the right end of support plate 103 bottom and base plate 101; Top plate 106 is arranged above the shaking seat 102, and the right end of the top plate 106 and the right end of the support plate 103 are connected by the side plate 105; the mixing tank 107 is arranged between the top plate 106 and the shaking seat 102, and the bottom is connected with the shakin...

Embodiment 2

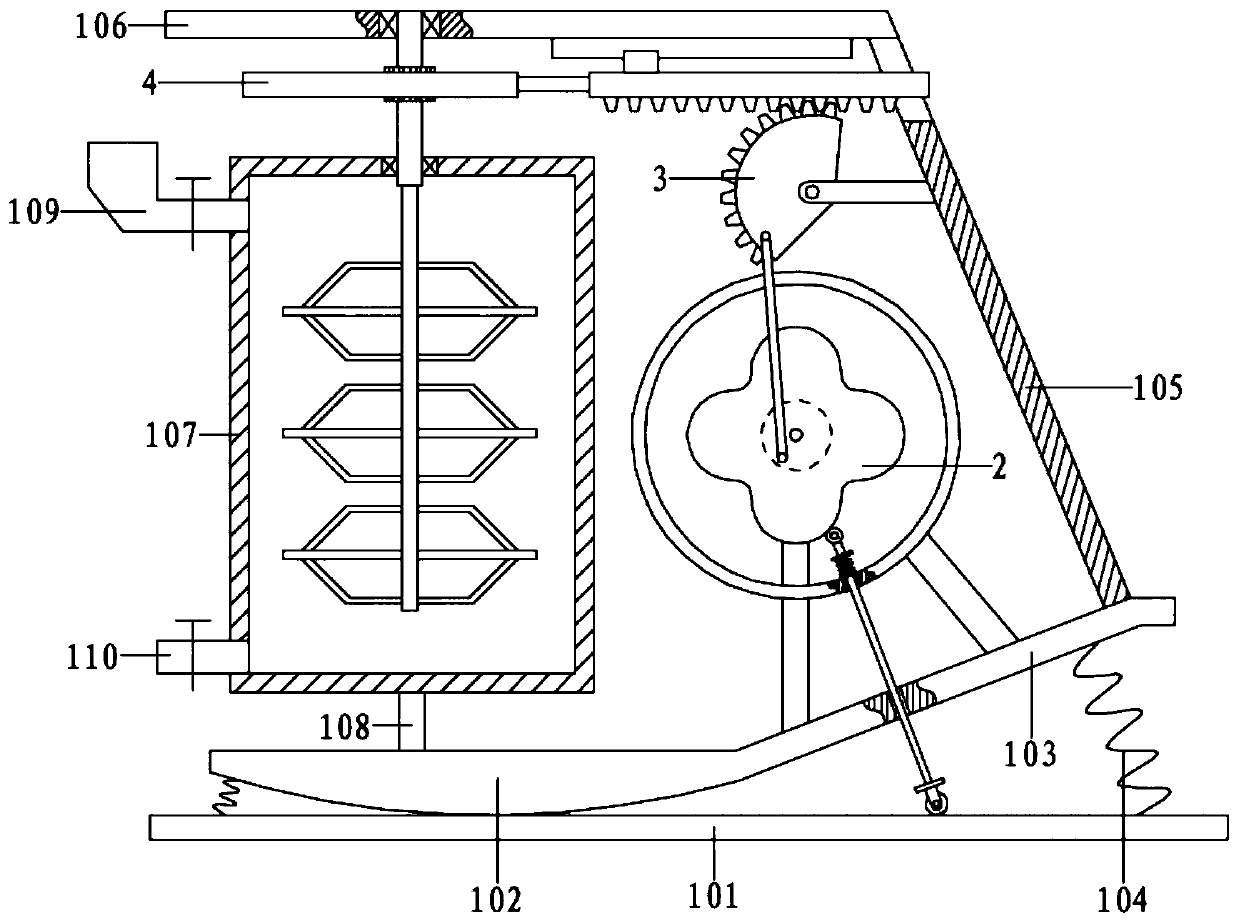

[0065] Referring to the accompanying drawings, a high-efficiency production equipment for swaying machine tool coolant includes a frame assembly 1, a sway assembly 2, a transmission assembly 3 and a mixing assembly 4;

[0066] The frame assembly 1 includes a bottom plate 101, a shaking seat 102, a support plate 103, a return spring 104, a side plate 105, a top plate 106 and a mixing tank 107; Connect with back-moving spring 104; The bottom of rocking seat 102 is an arc surface, and overlaps with base plate 101; Rocking seat 102 right end is connected with support plate 103, also is connected with return spring 104 between the right end of support plate 103 bottom and base plate 101; Top plate 106 is arranged above the shaking seat 102, and the right end of the top plate 106 and the right end of the support plate 103 are connected by the side plate 105; the mixing tank 107 is arranged between the top plate 106 and the shaking seat 102, and the bottom is connected with the shakin...

Embodiment 3

[0078] The difference from Example 2 is that

[0079] It also includes a reciprocating assembly 5 and a lifting assembly 6; the reciprocating assembly 5 is arranged above the top plate 106, and the right end of the reciprocating assembly 5 cooperates with the mixing assembly 4 through the elevating assembly 6.

[0080] The reciprocating assembly 5 includes No. 3 connecting rod 501, No. 4 connecting rod 502, No. 2 slider 503, No. 2 slide rail 504, moving block 505 and inclined groove 506;

[0081] The right end of the No. 1 rack 304 passes through the side plate 105 and is connected with the No. 3 connecting rod 501; the No. 3 connecting rod 501 is higher than the top plate 106 after being bent, and the bending section extends to the left and is connected with the moving block 505; There is No. 2 slide rail 504, and the bending section is connected with No. 2 slide block 503 through No. 4 connecting rod 502, and No. 2 slide block 503 is slidingly connected with No. 2 slide rail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com