Vacuum casting pattern coating system

A vacuum casting and coating technology, which is applied to casting molding equipment, casting molds, and casting mold components. It can solve the problems of quality impact of casting products, loss of pattern surface coating, and easy knotting on drying racks, etc., to ensure drying Quality, improvement of coating efficiency and coating uniformity, effects of ensuring uniformity and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] In order to make the objects and advantages of the present invention clearer, the present invention will be described in detail below in conjunction with the examples. It should be understood that the following words are only used to describe one or several specific implementation modes of the present invention, and do not strictly limit the protection scope of the specific claims of the present invention. As used herein, the terms "parallel" and "perpendicular" are not limited to their strict geometric definitions, but include reasonable and inconsistent tolerances for machining or human error;

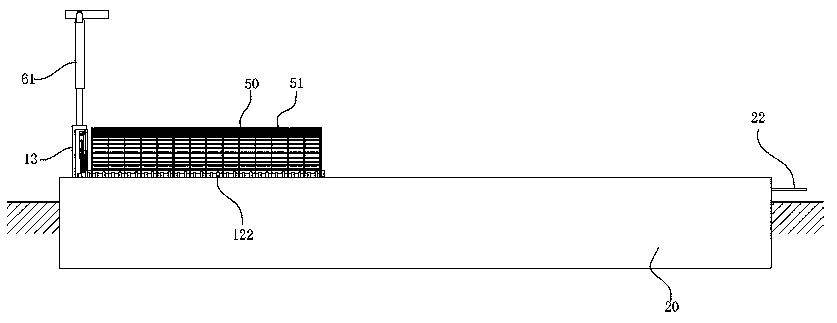

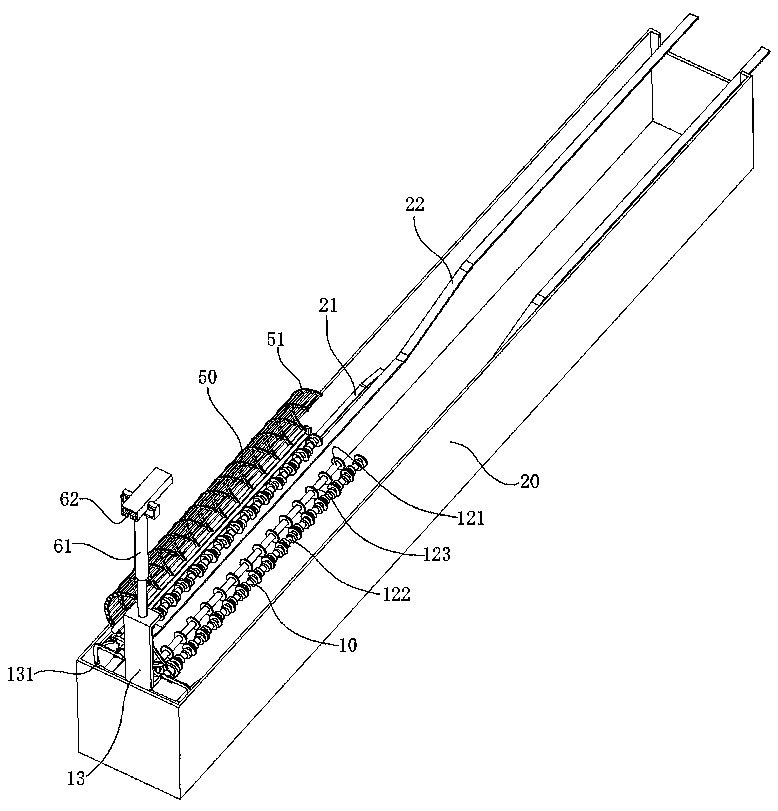

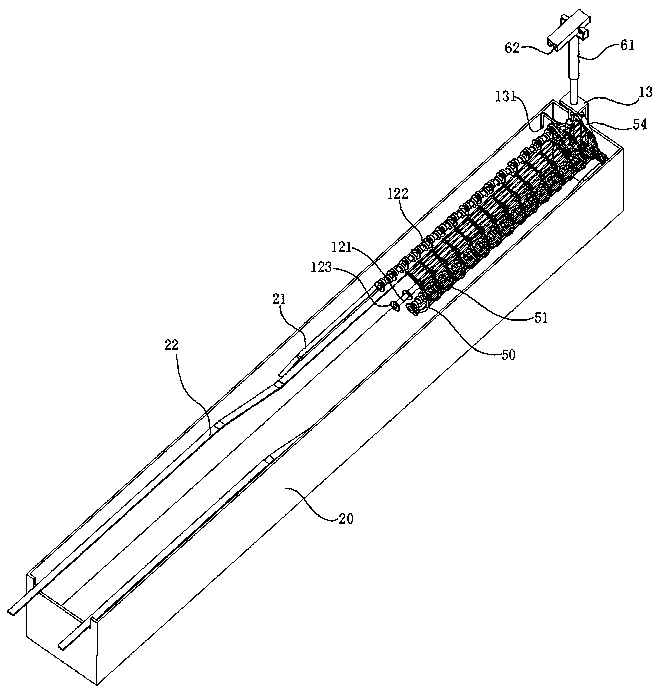

[0058] Attached below Figure 1 to Figure 24 , the vacuum casting model coating system of the present invention is described in detail:

[0059] A vacuum casting pattern coating system, comprising a coating bracket 10, the transfer mechanism drives the coating bracket 10 to reciprocate between the coating tank 20 and the feed inlet of a drying rack 30, and the drying rack 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com