Energy-saving and environment-friendly polyester fiber cleaning device

A polyester fiber, energy saving and environmental protection technology, applied in the field of polyester fiber processing, can solve the problems of inconvenient disassembly and replacement, no dehydration function, poor cleaning effect, etc., to increase functionality, increase cleaning methods and cleaning effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

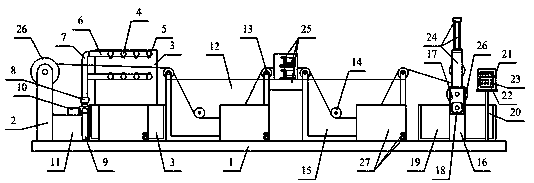

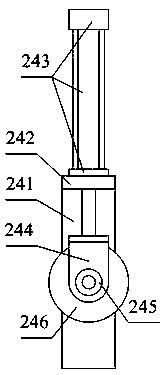

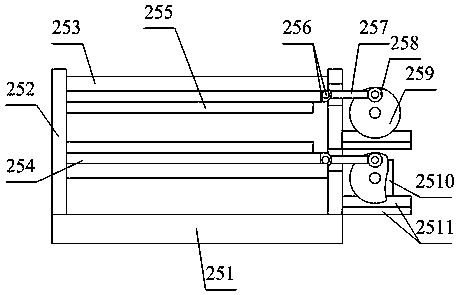

[0044] as attached figure 1 to attach figure 2 As shown, an energy-saving and environment-friendly polyester fiber cleaning device includes a fixed bottom plate 1, a left support plate 2, a collection box frame 3, a longitudinal spray pipe 4, a spray head 5, a horizontal connecting pipe 6, and a first conveying pipe 7 , water separator 8, second delivery pipe 9, first water pump 10, cleaning liquid tank 11, cleaning pool 12, first guide rolling shaft 13, second guiding rolling shaft 14, rinsing tank 15, right support plate 16, deceleration device 17, receiving material motor 18, collecting box 19, support column 20, protective shell 21, PLC22, drive switch 23, movable dehydration frame structure 24, auxiliary activity cleaning frame structure 25, detachable connecting plate structure 26 and filterable The processing box structure 27, the left support plate 2 is respectively welded to the front and rear parts on the left side of the upper surface of the fixed bottom plate 1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com