Antibacterial and breathable composite yarn and manufacturing method thereof

A manufacturing method and technology of composite yarn, which is applied in the field of composite yarn, can solve the problems of poor antibacterial air permeability and cumbersome manufacturing methods, and achieve the effects of antibacterial air permeability, beautiful finished products, and simple and quick manufacturing methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

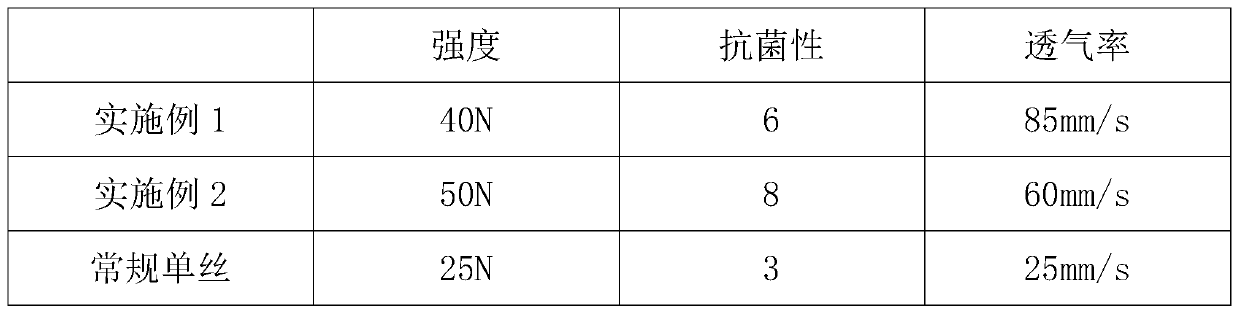

Embodiment 1

[0022] A method for manufacturing an antibacterial and breathable composite yarn, comprising the steps of:

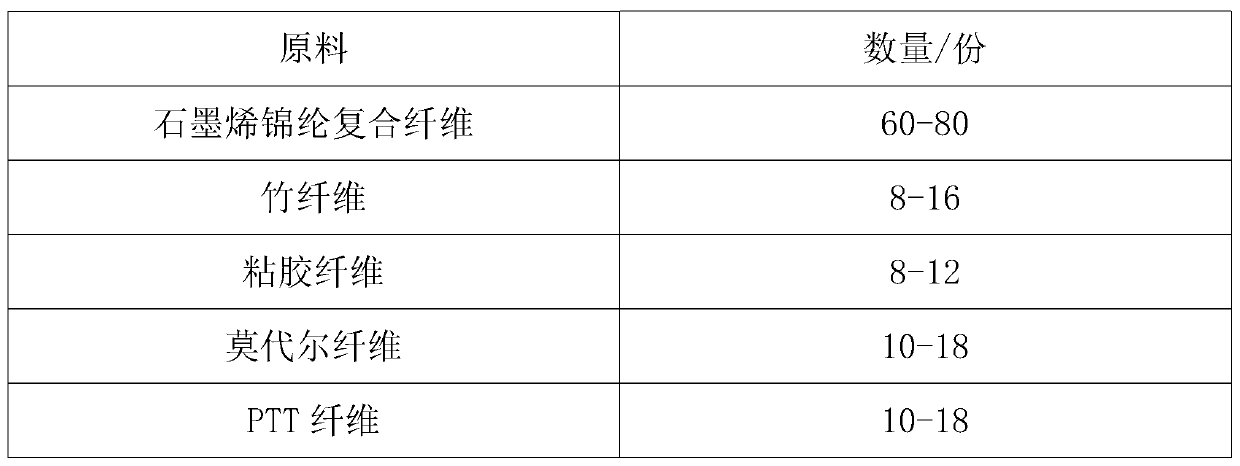

[0023] Blowing process: Blend the five raw material fibers of graphene nylon composite fiber, modal fiber, viscose fiber, bamboo fiber and PTT fiber. Before blending, add 1.5% antistatic agent and 1.5% moisturizing agent. After blending The fiber is fed into the cotton box blender, and the cotton lap is made by the lapping machine, and the cotton lap weight is 370g / m;

[0024] Carding process: manual proportioning and weighing→mixing→opening→carding, continuous weighing and quantitative feeding in the mixing warehouse, soft opening through fan negative pressure extraction;

[0025] Drawing process: Trützschler HSR1000 drawing frame is used, the main parameters of the process are two-way combining, the delivery speed is 260m / min, the drafting ratio is 3, and the dry weight of the sliver is 15 / 5m, so as to obtain better fiber straightening degree and evenness, drawing ro...

Embodiment 2

[0032] A method for manufacturing an antibacterial and breathable composite yarn, comprising the steps of:

[0033] Blowing process: Blend the five raw material fibers of graphene nylon composite fiber, modal fiber, viscose fiber, bamboo fiber and PTT fiber. Before blending, add 1.5% antistatic agent and 1.5% moisturizing agent. After blending The fiber is fed into the cotton box blender, and the cotton lap is made by the lapping machine, and the cotton lap quantitative is 420g / m;

[0034] Carding process: manual proportioning and weighing→mixing→opening→carding, continuous weighing and quantitative feeding in the mixing warehouse, soft opening through fan negative pressure extraction;

[0035] Drawing process: Trützschler HSR1000 drawing frame is used, the main parameters of the process are two-way combining, the delivery speed is 260m / min, the drafting ratio is 8, and the dry weight of the sliver is 18 / 5m, so as to obtain better fiber straightening degree and evenness, draw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com