Stay cable construction tensioning method

A cable-stayed cable and cable-stayed beam technology, which is applied to the construction of cable-stayed bridges, can solve the problems of long construction period, high cost, waste of labor and machinery, etc., and achieve the effects of fewer construction procedures, improved construction efficiency, and accelerated construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The content of the present invention will be described below in conjunction with specific embodiments.

[0021] 1. Construction preparation

[0022] A. Cable stays approaching the site: The cable supply plan should take into account the installation progress on site and the actual stacking capacity on site. In principle, the number of cables stacked on the bridge deck should not be less than one cable number and be stored under the main tower to prevent the weight of the cables from affecting the load control of the main bridge during construction. Others are piled up nearby at the construction site.

[0023] Special slings are used for transportation and hoisting (single load bearing 10 tons), and 3 lifting points are set along the periphery of the cable during hoisting, so that the cables are evenly stressed and ensure that the stay cables PE are not damaged.

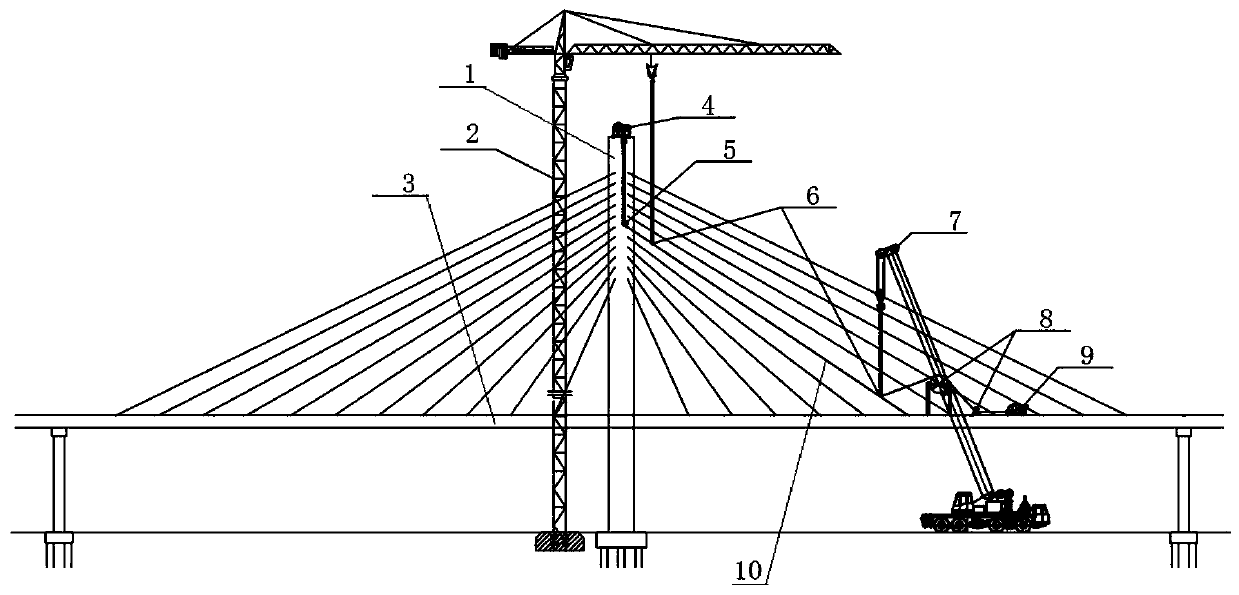

[0024] B. Construction equipment layout: such as figure 1 As shown, after the construction conditions ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com