In-plane asymmetric magnetic memory unit and preparation method

A magnetic storage unit, asymmetric technology, applied in the field of information technology and microelectronics, can solve the problems of increasing cost, high price, and increasing complexity and difficulty of semiconductor process, so as to prolong working life, reduce energy consumption, reduce cost and process effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with specific embodiments and with reference to the accompanying drawings. For clarity, components in the drawings may not be drawn to scale. Also, some components may be omitted from the drawings. It is contemplated that elements and features of one embodiment may be beneficially incorporated in another embodiment without further recitation.

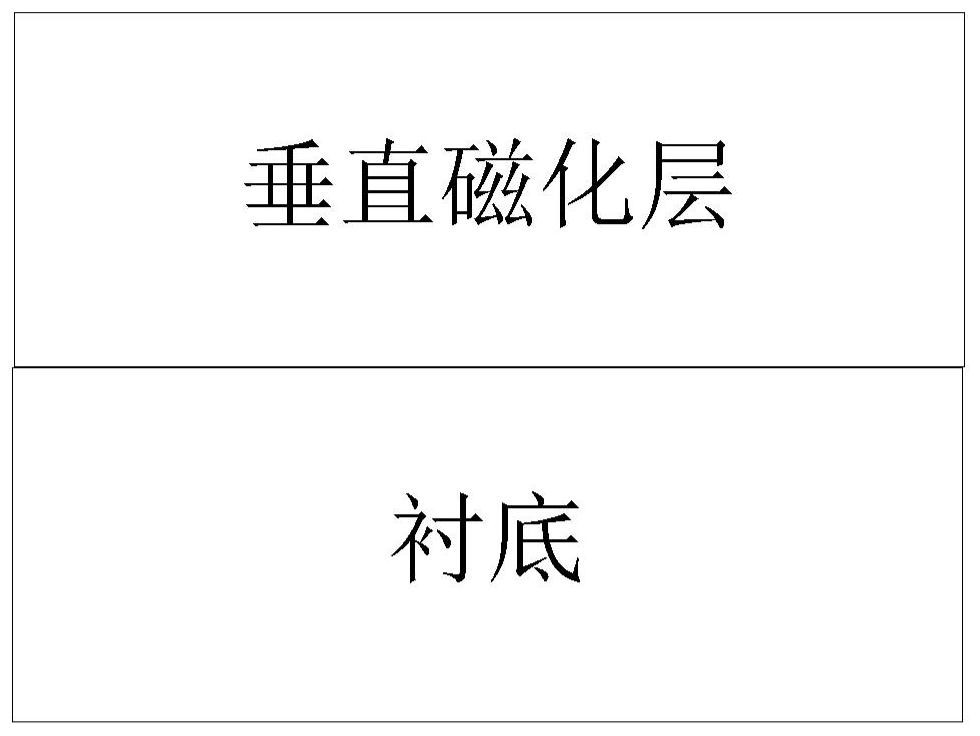

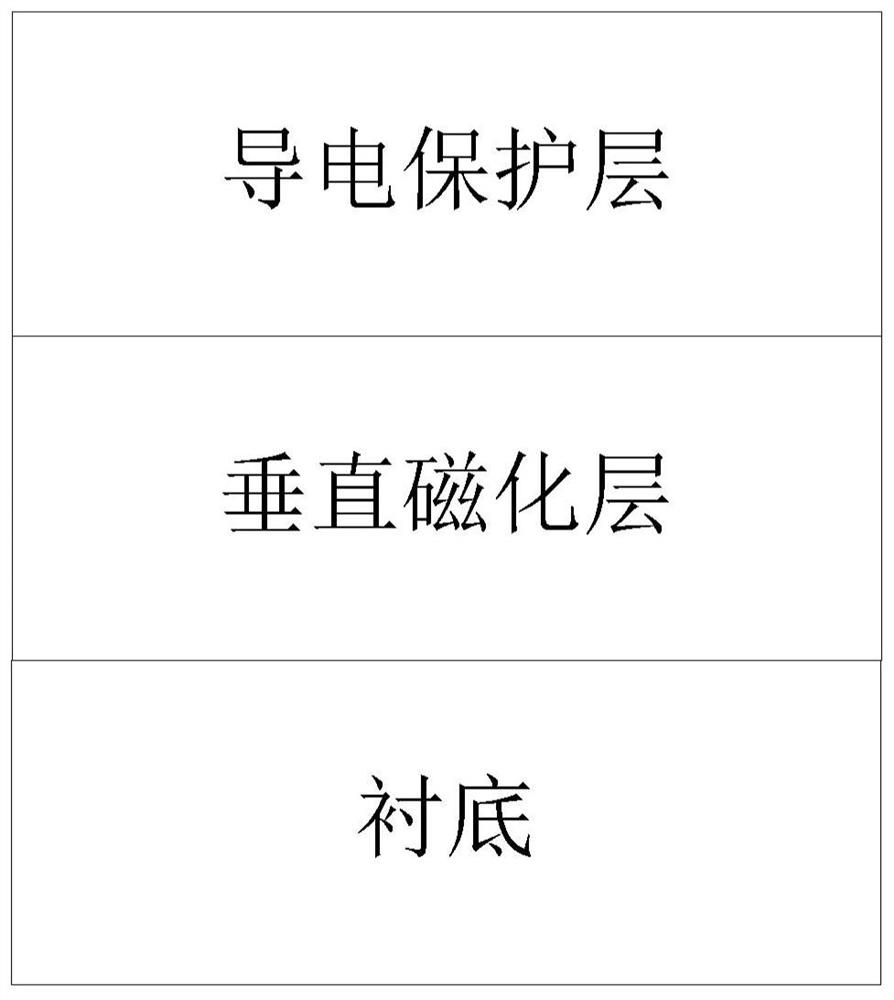

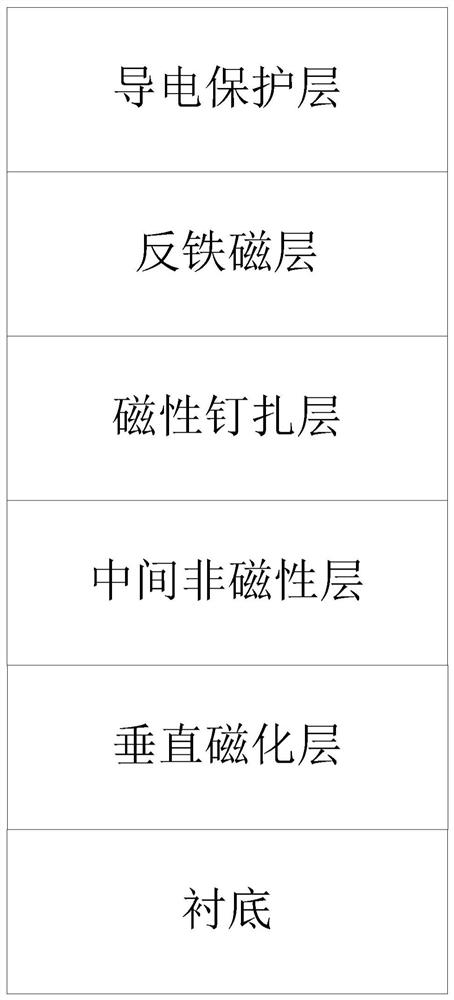

[0035] The present invention provides an in-plane asymmetric magnetic memory unit, such as figure 1 As shown, the magnetic memory unit includes: a substrate; and a perpendicular magnetization layer located on the substrate; by heating the perpendicular magnetization layer, the asymmetry of the film plane direction is generated in the perpendicular magnetization layer (ie The asymmetry of the film surface direction of the perpendicular magnetization film l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com