Method for removing chlorine from fly ash

A technology of alkali metal carbonates and mixtures, which is applied in the field of dust removal and chlorine removal, and can solve the problems of lead-zinc powder having no value in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

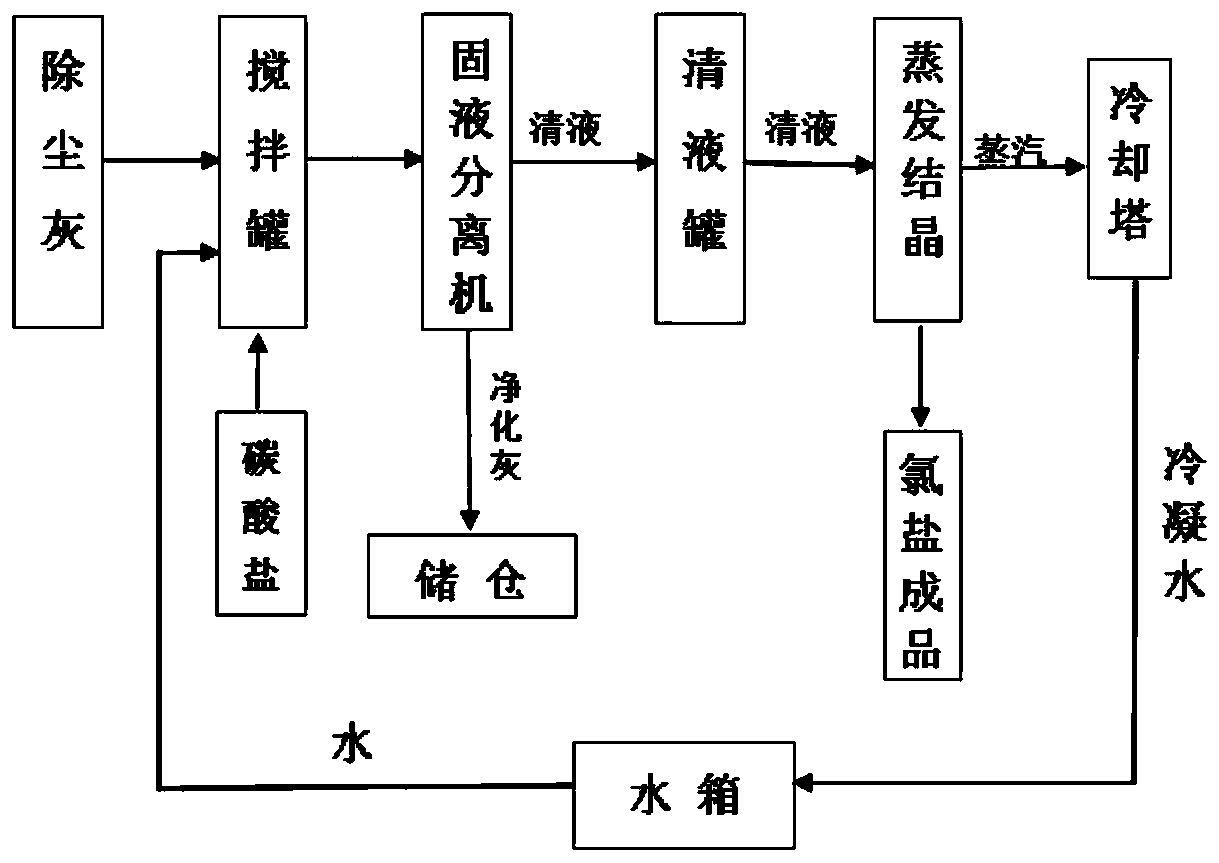

Method used

Image

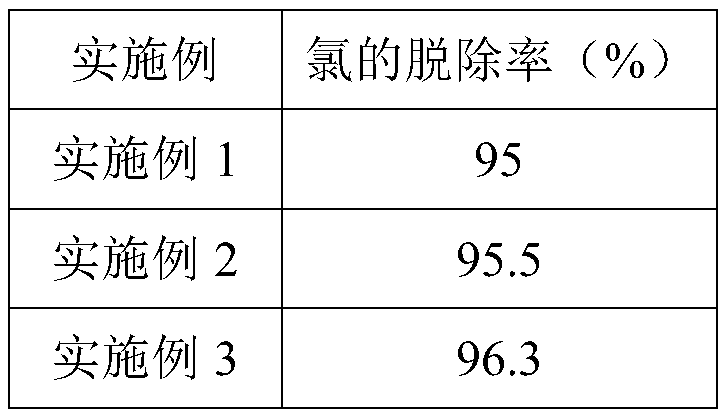

Examples

Embodiment 1

[0050] A kind of method for dust removal chlorine, by weight, comprises the following steps:

[0051] 1) Add 100 parts of chlorine-containing 1.5% (mass) dedusting ash, 1900 parts of water and 5 parts of sodium carbonate into the mixing tank, and stir for 5 minutes at a temperature of 20° C. to obtain a mixture;

[0052] 2) using a fully automatic filter press to carry out solid-liquid separation of the mixture obtained in step 1);

[0053] 3) Send the solid (i.e. purified ash) obtained in step 2) back to the original dust removal ash recovery system of the enterprise for recycling; the solution obtained in step 2) is sent to the evaporation crystallizer, and the evaporated steam is condensed and then returned to the water tank. The crystallized sodium chloride is dehydrated to obtain the finished salt.

[0054] The dedusting ash is the dedusting ash in the ironmaking process.

Embodiment 2

[0056] A kind of method for dust removal chlorine, by weight, comprises the following steps:

[0057] 1) Add 20 parts of chlorine-containing 2% (mass) dedusting ash, 80 parts of water and 3 parts of sodium carbonate in a stirring tank, and stir for 5 minutes at a temperature of 50° C. to obtain a mixture;

[0058] 2) using a fully automatic filter press to carry out solid-liquid separation of the mixture obtained in step 1);

[0059] 3) Send the solid (i.e. purified ash) obtained in step 2) back to the original dust removal ash recovery system of the enterprise for recycling; the solution obtained in step 2) is sent to the evaporation crystallizer, and the evaporated steam is condensed and then returned to the water tank. The crystallized sodium chloride is dehydrated to obtain the finished salt.

[0060] The dedusting ash is the dedusting ash in the ironmaking process.

Embodiment 3

[0062] A kind of method for dust removal chlorine, by weight, comprises the following steps:

[0063] 1) Add 30 parts of chlorine-containing 2% (mass) dedusting ash, 70 parts of water and 1.5 parts of sodium carbonate into the mixing tank, and stir for 5 minutes at a temperature of 80°C to obtain mixture 1;

[0064] 2) using a fully automatic filter press to separate the mixture 1 from solid to liquid;

[0065] 3) Add mixture 1 to a stirring tank, add 70 parts of water and 1.5 parts of sodium carbonate at the same time, stir at a temperature of 80°C for 5 minutes, and obtain mixture 2;

[0066] 4) The mixture 2 is subjected to solid-liquid separation;

[0067] 5) The solid (i.e. purified ash) obtained in step 4) is returned to the original dust removal ash recovery system of the enterprise for recycling; the solution obtained in step 2) is sent to the evaporation crystallizer, and the evaporated steam is condensed and then returned to the water tank. The crystallized sodium ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com