Cutting machine tool for machining metal members

A technology for cutting machine tools and metal components, applied to metal processing machine parts, metal processing equipment, manufacturing tools, etc., can solve problems such as surface damage of metal components, imperfect technology, scratches on the inner wall of metal component slots, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

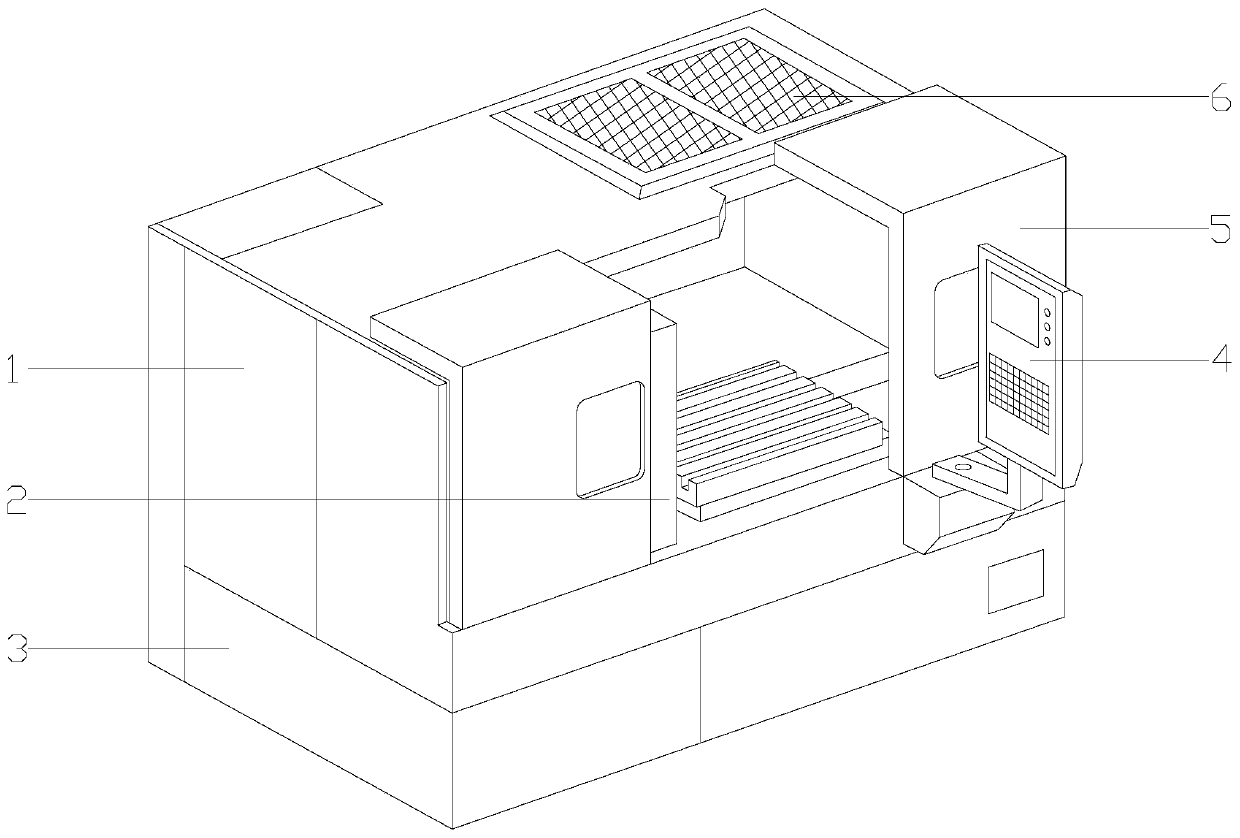

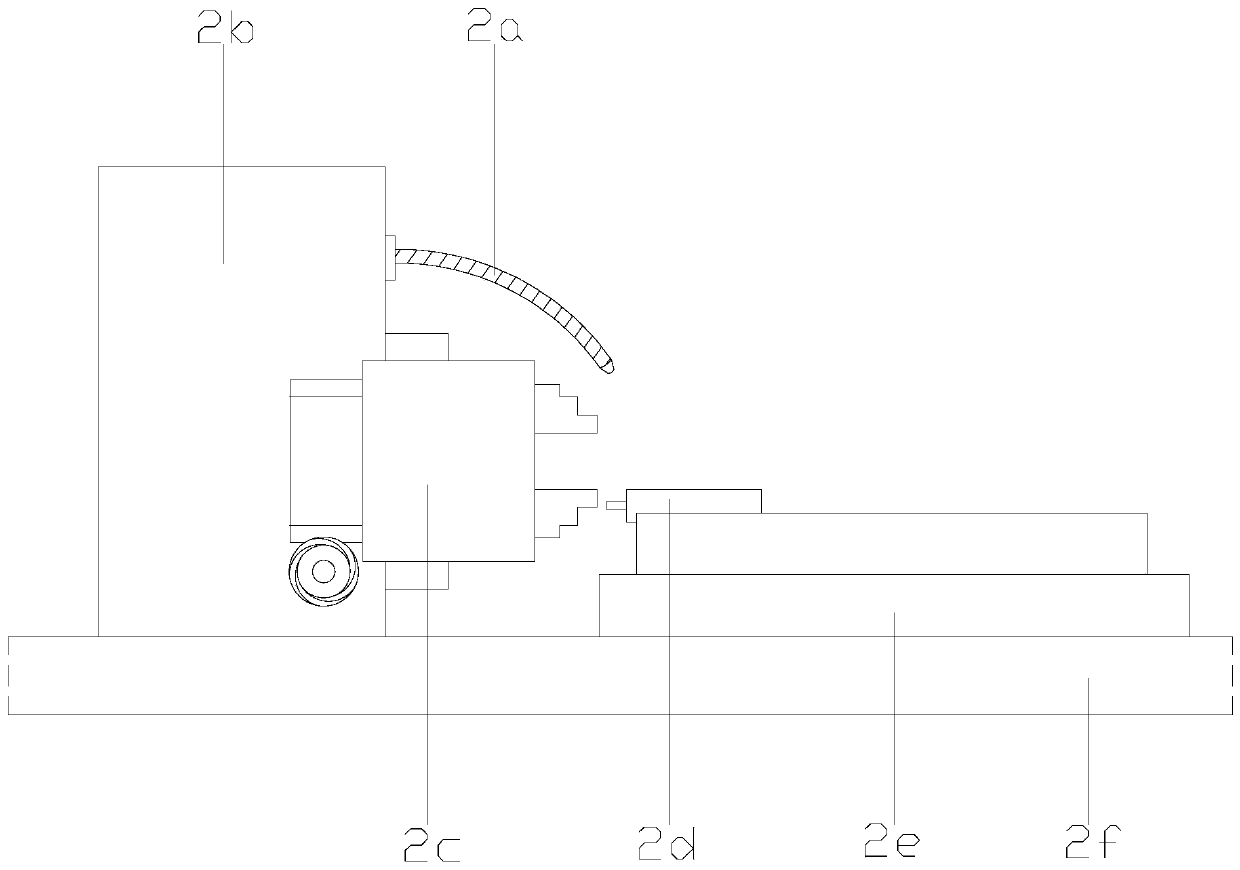

[0023] see Figure 1-Figure 4, the present invention provides a cutting machine tool for processing metal components, the structure of which includes a machine tool protective cover 1, a component cutting mechanism 2, a support base 3, an intelligent controller 4, a protective door panel 5, a dust-proof heat dissipation net 6, and the support base 3 It has a rectangular structure and is installed horizontally on the workshop floor. The machine tool protective cover 1 is located above the support base 3 and close together. The component cutting mechanism 2 is nested inside the machine tool protective cover 1. The protective door panel 5 is located on the machine tool The left and right sides of the front of the protective cover 1 adopt clearance fit. The intelligent controller 4 is fixed on the right side of the front of the machine tool protective cover 1 by bolts. The dust-proof and heat dissipation net 6 is nested on the top of the machine tool protective cover 1. Mechanism ...

Embodiment 2

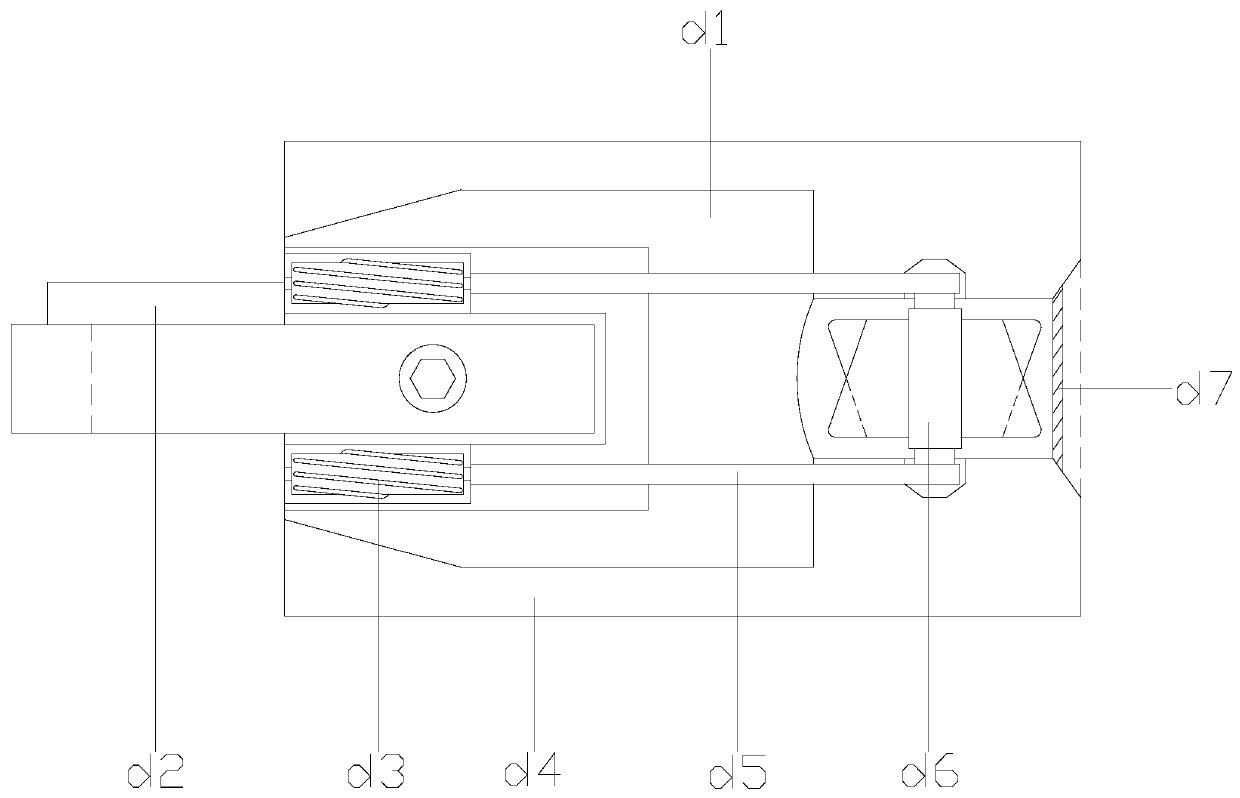

[0026] see Figure 5-Figure 6 , the automatic chip breaker d2 is composed of a fixed knob d21, a chip breaker blade d22, a waste chip guide cavity d23, a chip breaker driving structure d24, a sliding adjustment rod d25, and a chip breaker support d26. The sliding adjustment rod d25 and It is located on the left side of the cutter fixing frame d4 and has an integrated structure. The chip breaker support d26 is located on the left side of the sliding adjustment rod d25 and adopts a clearance fit. The fixed knob d21 and the sliding adjustment rod d25 are threaded. The waste guide cavity d23 is connected through the left bottom of the chip breaker support d26, the chip breaker driving structure d24 is located above the waste guide cavity d23, and the chip breaker blade d22 is located at the left end of the upper surface of the chip breaker support d26, The sliding adjustment rod d25 and the chip breaker support d26 are parallel to each other. The chip breaking driving structure d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com