Garbage efficient disposal facility for mechanical production

A technology for processing equipment and garbage, applied in the direction of presses, material forming presses, magnetic separation, etc., can solve the problems of slow metal decomposition, inconvenient disposal, soil hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

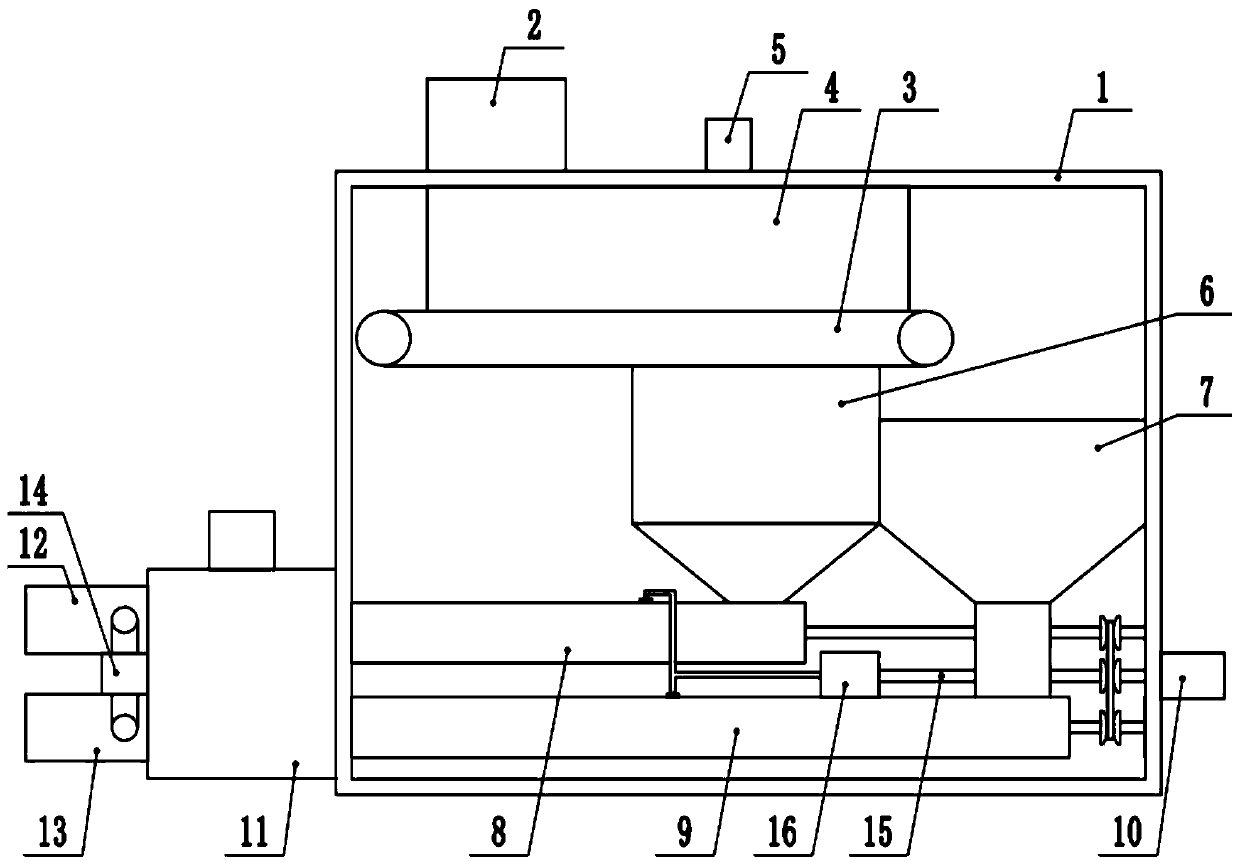

Embodiment 1

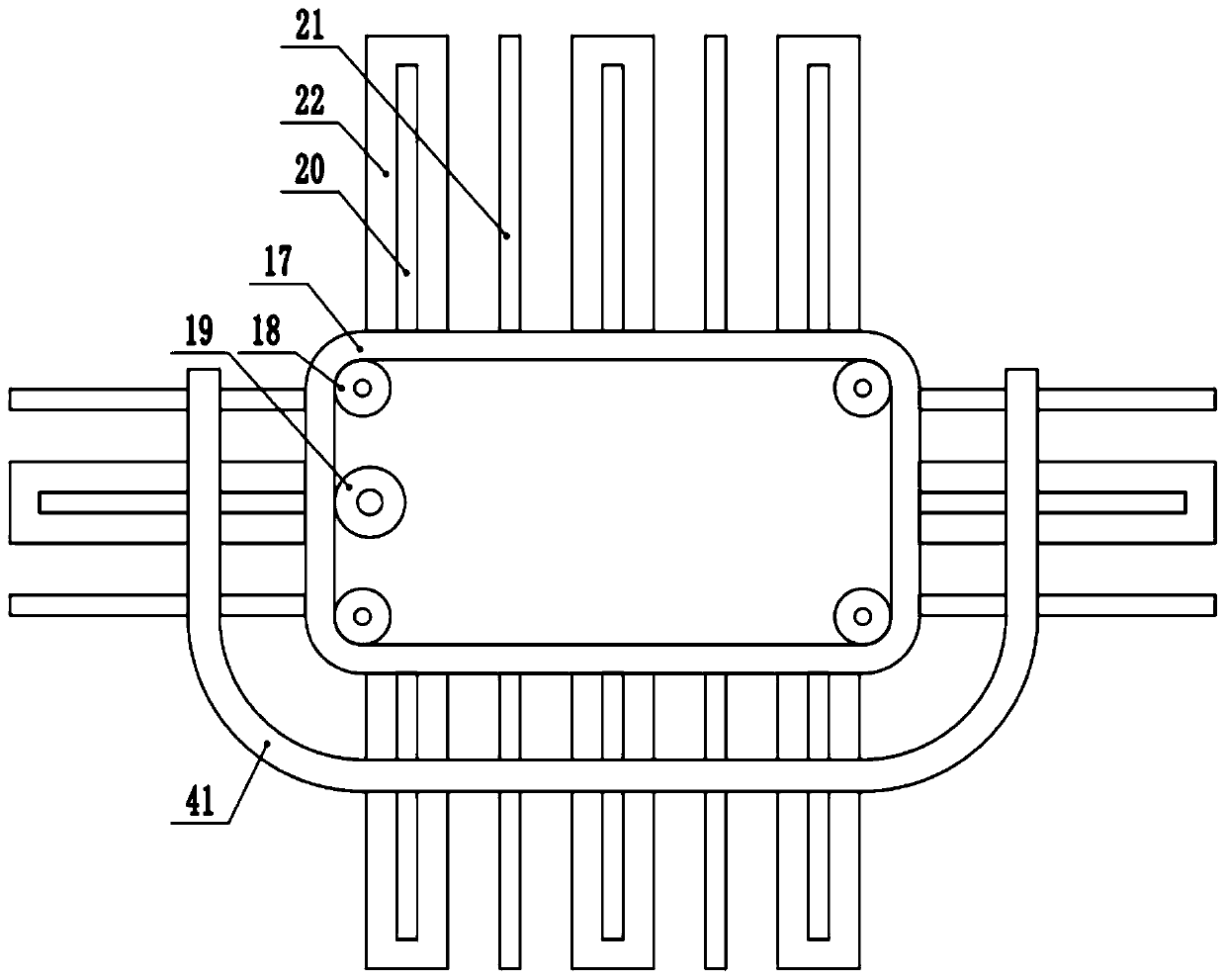

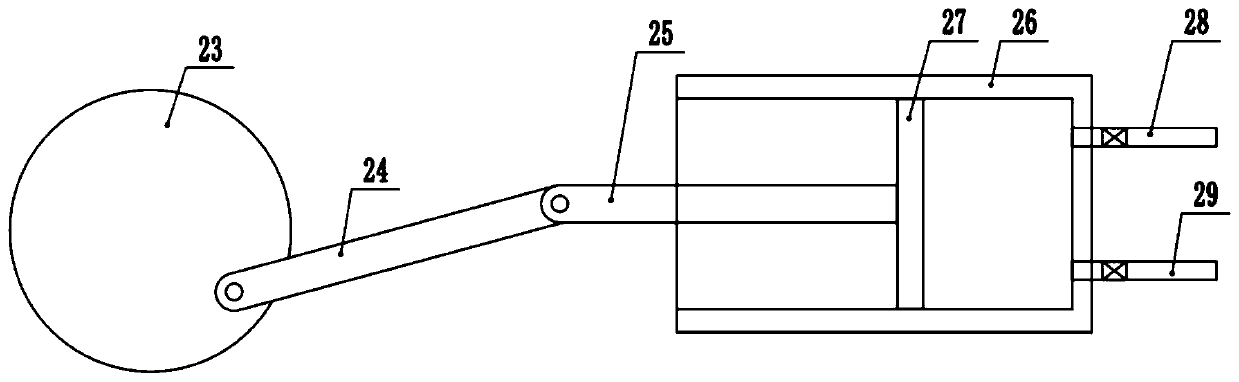

[0028] see Figure 1-7 , a kind of high-efficiency waste treatment equipment for mechanical production, comprising a treatment box 1, one end of the top of the treatment box 1 is fixedly connected to the feed hopper 2, the top end of the treatment box 1 is fixedly connected to the baffle 4, and the bottom of the baffle 4 is provided with a feeding Conveyor belt 3, feed conveyer belt 3 is driven by external drive equipment, the below of one end of feed conveyer belt 3 is provided with the second unloading cover 7, and one side of feed conveyer belt 3 is provided with adsorption separation device, the adsorption separation device The bottom is provided with a first blanking cover 6, and the bottom ends of the first blanking cover 6 and the second blanking cover 7 are respectively fixedly connected to the first forming output pipe 8 and the second forming output tube 9, the first forming output tube 8 and the second forming output pipe 9 are provided with a hybrid molding conveyi...

Embodiment 2

[0038] see Figure 1-7 , The other content of this embodiment is the same as that of Embodiment 1, except that: the bottom end of the dispersing frame 21 is fixedly provided with a plurality of dispersing claws 40 .

[0039]In the implementation process of the present invention, the metal debris produced by mechanical production is poured from the feed hopper 2, and then the external drive equipment is started to make the feed conveyor belt 3 run, and then the first drive motor 5 and the second drive motor 10 are started, The first drive motor 5 drives the drive gear 19 to rotate so that the transmission belt 17 drives the fixed rod 20, the dispersion frame 21 and the electromagnetic plate 22 to move. The ferrous material on the material conveyor belt 3 is absorbed until the fixed rod 20 breaks away from the conductive rail 41, the electromagnetic plate 22 loses its magnetism, and the ferrous material falls into the first blanking cover 6 below, and the non-ferrous material is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com