Method for recovering thallium from flue gas and equipment for implementing method

A flue gas and equipment technology, applied in the field of environmental protection, can solve the problems of water consumption, excessive calcium impurities, water waste, etc., and achieve the effect of low operating cost, non-toxic cost, good circulation and recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

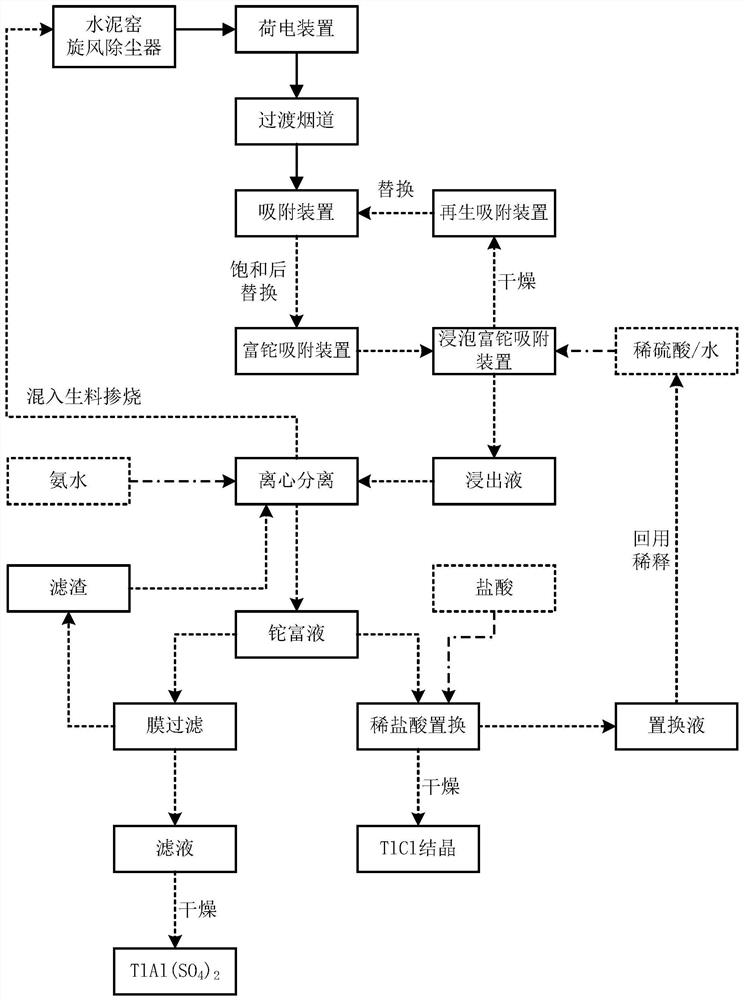

[0092] 1. For the cement kiln process equipped with a waste heat boiler, a charging device and a honeycomb titanium-containing adsorption device are arranged in the flue between the cyclone dust collector and the waste heat boiler, and the fine particles containing thallium after conditioning by the charging device are adsorbed on the honeycomb On the titanium-containing adsorption device, the thallium-rich adsorption device is obtained by regular replacement, and the specific surface area of the titanium-based porous material is 70-80m 2 / g; the specific process is as follows, and the accompanying drawings are as follows Figure 4 Shown:

[0093] A. A charging device is installed in the high temperature section of the vertical flue (about 300°C) after the outlet of the cyclone dust collector. The flue gas passes through the flat charging device (satisfies the DC electrostatic field current of more than 40μA), forming charged thallium dust and moving downward. ;

[0094] B...

Embodiment 2

[0101] 1. For conventional cement kilns equipped with electrostatic precipitator for secondary recovery of clinker, an adsorption device is arranged directly behind the electrostatic precipitator, and the pre-charging function is realized by the electrostatic precipitator, that is, the electrostatic precipitator is the charging device (to meet the DC electrostatic field Current 40μA or more), the thallium-containing microparticles after conditioning are adsorbed on the vertical honeycomb titanium adsorption device, and the thallium-rich adsorption device is obtained by regular replacement. The specific surface area of the titanium-based porous material in the vertical honeycomb titanium adsorption device is 70 -80m 2 / g, the specific process is as follows, and the drawings are as follows Figure 5 Shown:

[0102] A. Install a vertical honeycomb titanium adsorption device after the outlet of the electrostatic precipitator (around 150°C);

[0103] B. The extremely fine thall...

Embodiment 3

[0110] 1. For cement kilns equipped with conventional high-temperature electrostatic precipitators + SCR denitrification devices, the adsorption device is arranged directly after the electrostatic precipitator and before the SCR, and the pre-charging function is realized by the electrostatic precipitator, that is, the electrostatic precipitator is the charging device (meeting DC electrostatic field current above 40μA), the thallium-containing microparticles after conditioning are adsorbed on the vertical honeycomb titanium-containing adsorption device, and the thallium-rich adsorption device is obtained by regular replacement. The specific surface area of the titanium-based porous material in the honeycomb titanium adsorption device is 70 -80m 2 / g, the specific process is as follows, and the drawings are as follows Figure 5 Shown:

[0111] A. Install a vertical honeycomb titanium-containing adsorption device after the outlet of the electrostatic precipitator (around 280°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com