Removal device and removal method of trace methane in krypton-xenon gas mixture

A mixed gas, krypton and xenon technology, applied in chemical instruments and methods, inert gas compounds, inorganic chemistry, etc., can solve the problem of difficult removal of methane, and achieve the effect of simple purification device, excellent removal effect and excellent purification effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

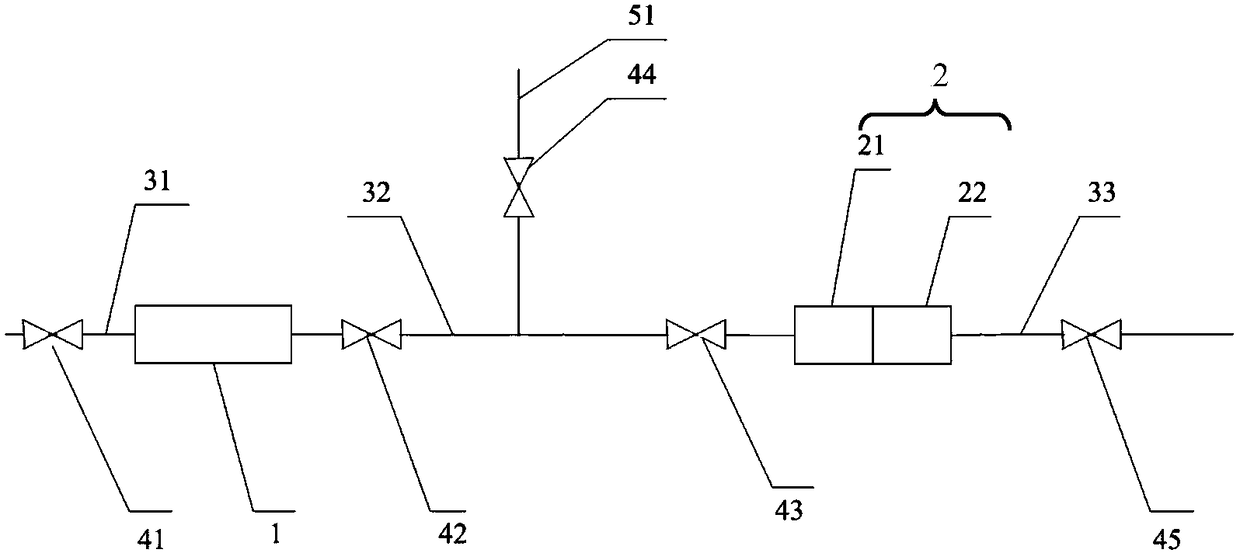

[0020] Embodiment 1: as figure 1 As shown, a device for removing trace amounts of methane in a krypton-xenon mixed gas according to the present invention includes a first purification pipe 1, a second purification pipe 2, a pipeline system and a valve system; the first purification pipe 1 is filled with particle diameter It is a 2-3mm 506TJW type demethanization catalyst, the second purification pipe 2 near the air inlet of the second purification pipe is the first adsorption layer 21, and the first adsorption layer 21 is a PEE type high-efficiency deoxygenation adsorbent; the second purification pipe The gas outlet is the second adsorption layer 22, the second adsorption layer is composed of 5A molecular sieve, the volume ratio of the first adsorption layer 21 and the second adsorption layer 22 is 1:1.

[0021] The pipeline system and valve system of this removing device comprise the first connection pipe 31 that is communicated with the first purification pipe inlet, the sec...

Embodiment 2

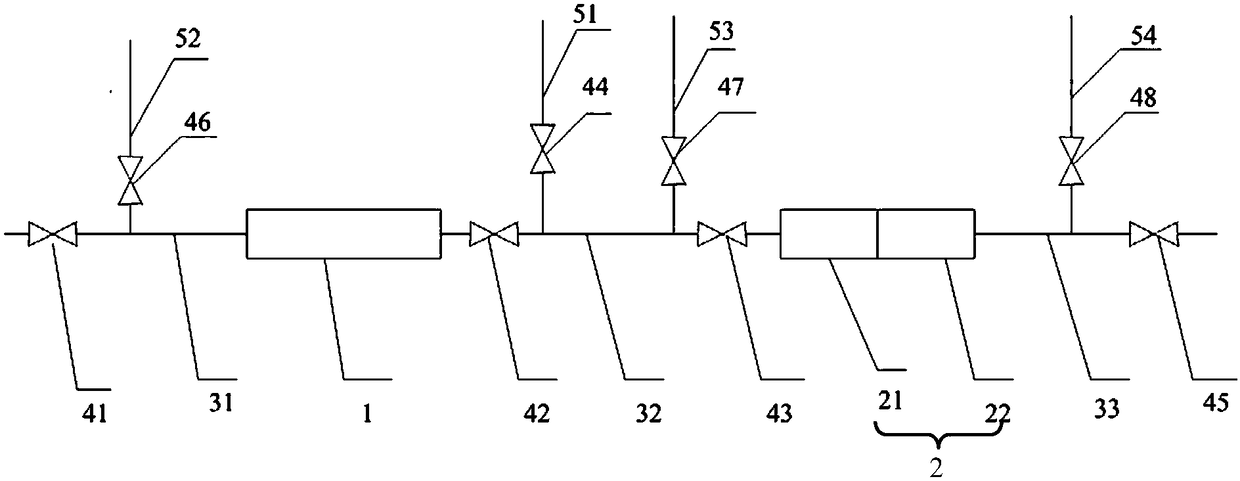

[0033] Such as figure 2 As shown, a device for removing trace amounts of methane in a krypton-xenon mixed gas according to the present invention includes a first purification pipe 1, a second purification pipe 2, a pipeline system and a valve system; the first purification pipe 1 is filled with particle diameter It is a 2-3mm 506TJW type demethanization catalyst, the second purification pipe 2 near the air inlet of the second purification pipe is the first adsorption layer 21, and the first adsorption layer 21 is a PEE type high-efficiency deoxygenation adsorbent; the second purification pipe The gas outlet is the second adsorption layer 22, the second adsorption layer is composed of 5A molecular sieve, the volume ratio of the first adsorption layer 21 and the second adsorption layer 22 is 1:1.

[0034]The pipeline system and valve system of this removing device comprise the first connection pipe 31 that is communicated with the first purification pipe inlet, the second conne...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com