Hydrodynamic cavitation system based on negative-pressure pore plate assisted positive-pressure pore plate and method for degrading dye wastewater

A technology of hydraulic cavitation and dye wastewater, applied in chemical instruments and methods, water pollutants, water/sewage treatment, etc., can solve the problems of rapid and thorough treatment of dye wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

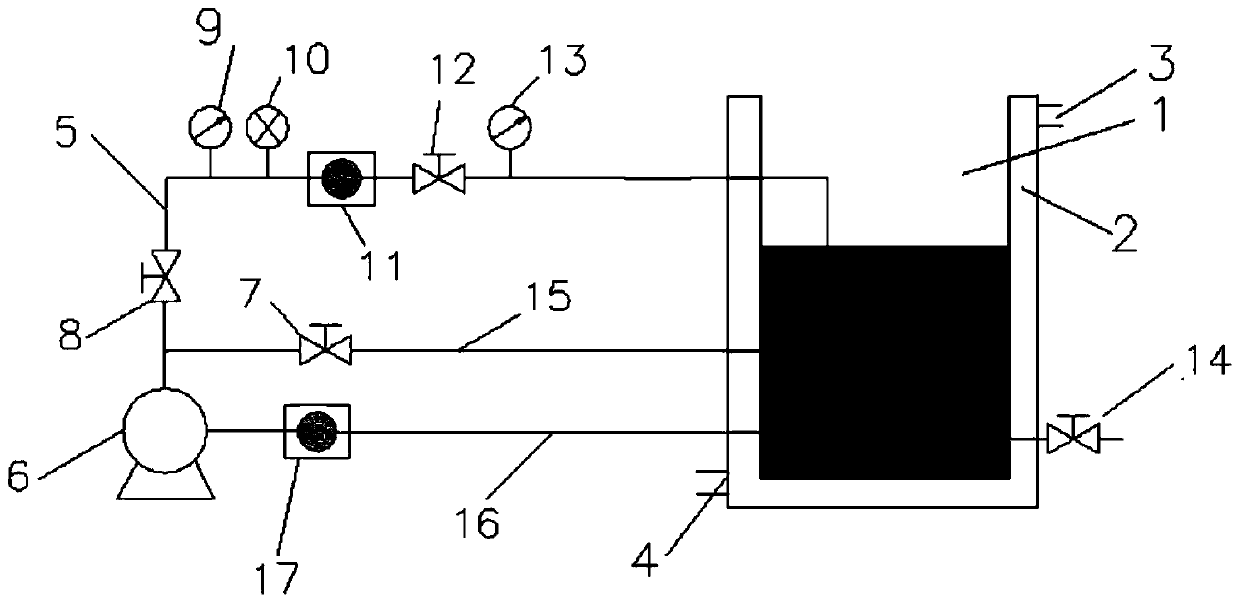

[0026] Such as figure 1 As shown, a hydraulic cavitation system based on negative pressure orifice assisted positive pressure orifice, including degradation tank 1, heat preservation device 2, main circulation pipeline 5, circulation pump 6, positive pressure orifice 11, secondary circulation pipeline 15, Suction pipeline 16 and negative pressure orifice 17.

[0027] Degradation tank 1 is used to hold wastewater containing dyes. The degradation tank 1 is provided with a thermal insulation device 2, the upper end of the thermal insulation device 2 is provided with a water outlet 3, and the lower end is provided with a water inlet 4. Through the water outlet 3 and the water inlet 4, circulating water circulates in the thermal insulation device to control the temperature in the degradation tank. within the setting range. The degradation tank 1 is provided with a sewage outlet 14 .

[0028] One end of the pumping pipeline 16 goes deep into the degradation tank 1, and the other ...

Embodiment 2

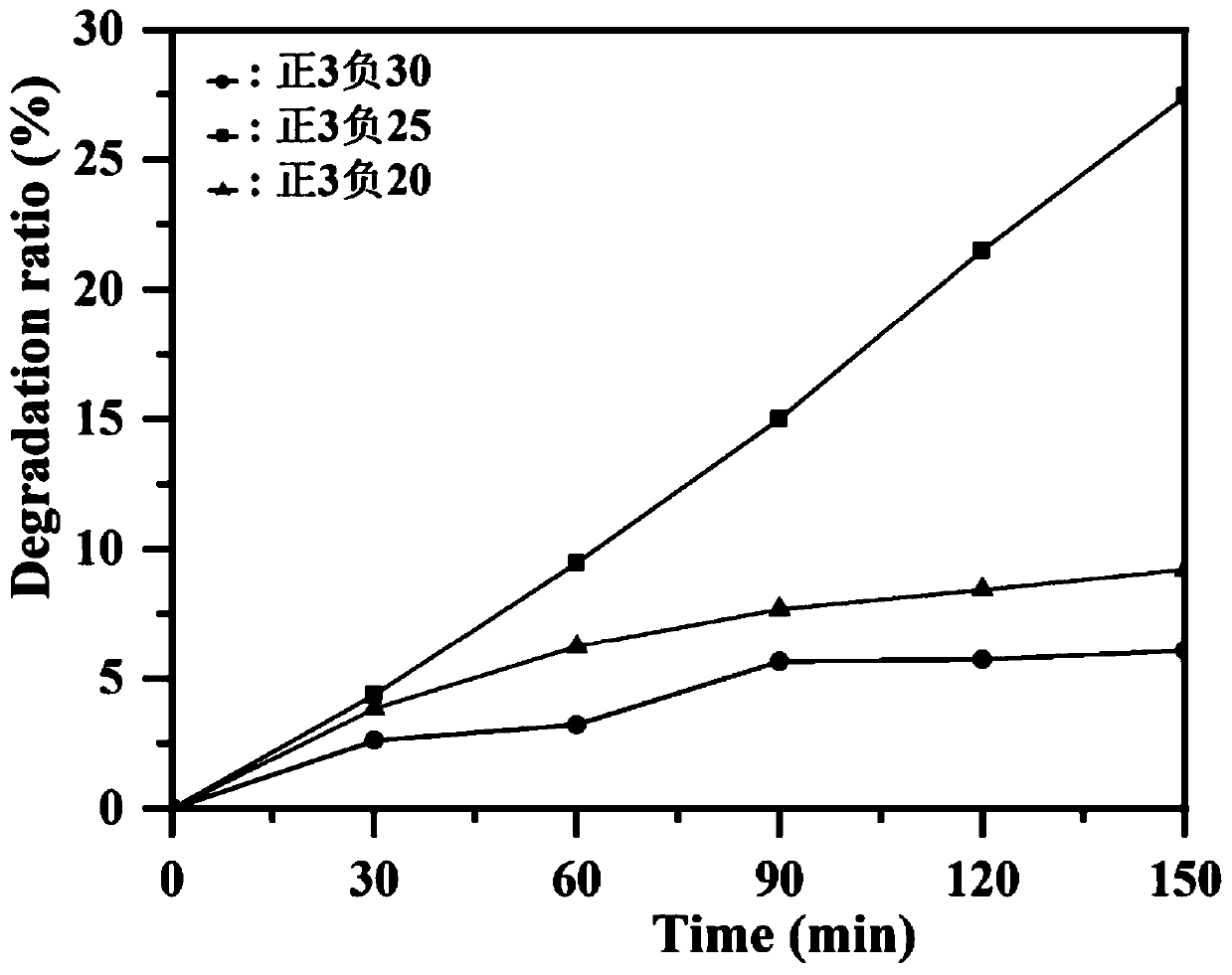

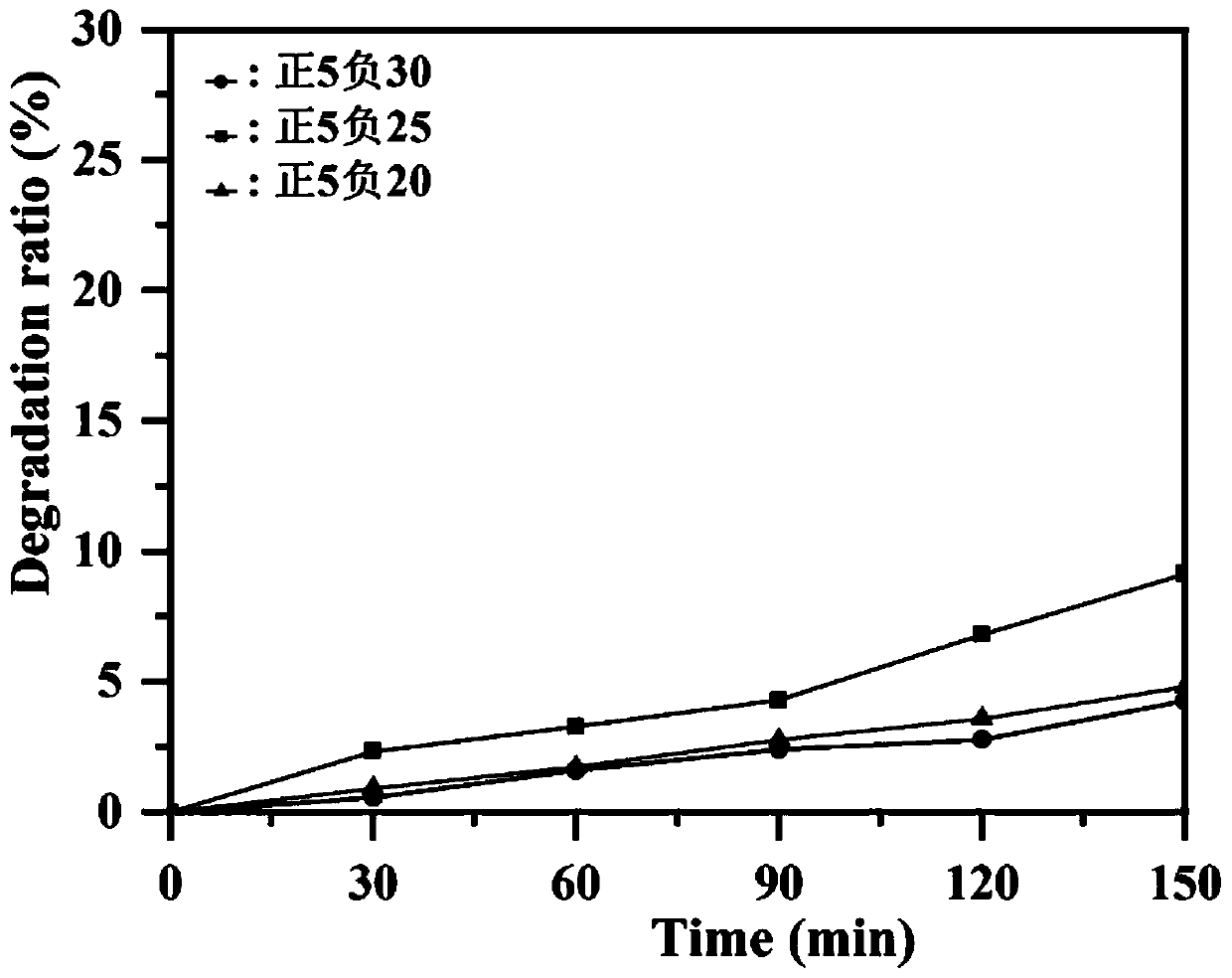

[0033] A method for degrading dye wastewater based on a negative-pressure orifice-assisted positive-pressure orifice hydraulic cavitation system

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com