Phosphogypsum treating agent, phosphogypsum treating method, preparation method of phosphogypsum filling material and phosphogypsum filling material

A technology of phosphogypsum and treatment agent, which is applied in the field of harmless treatment of solid waste, and can solve problems such as high material cost, lack of effective use of gypsum, and obstacles to treatment technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

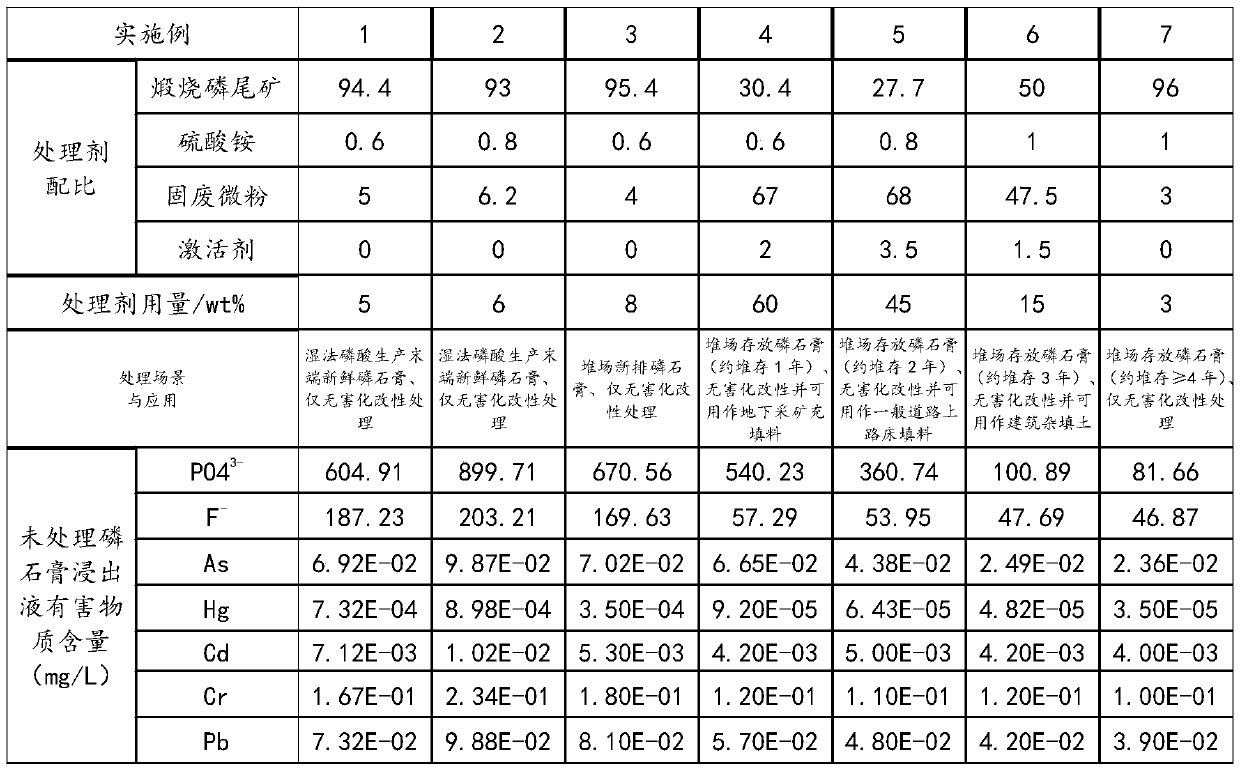

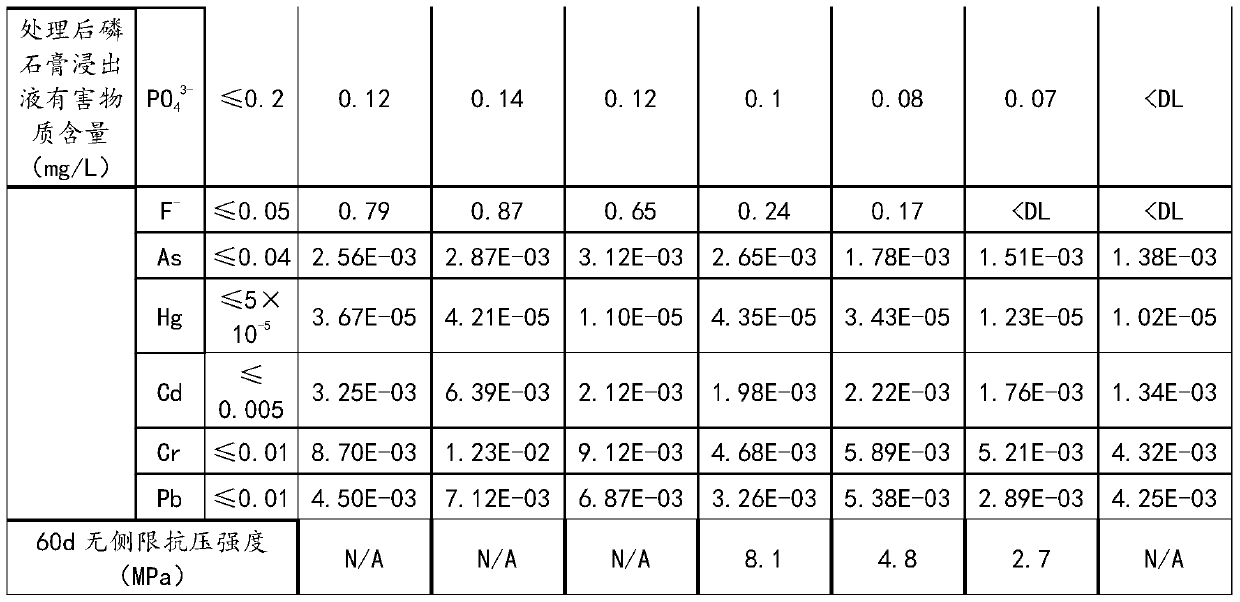

Embodiment 1

[0055] A phosphogypsum treatment agent, comprising the following components in mass percentage: 94.4% of calcined phosphorus tailings, 0.6% of ammonium sulfate, 5% of solid waste fine powder and 0% of activator. The above-mentioned phosphogypsum treatment agent is used for wet-process phosphoric acid to produce terminal fresh phosphogypsum, and the dosage of the treatment agent is 5% of the solid matter in the phosphogypsum, and the PO in the phosphogypsum leachate before and after treatment 4 3- , F - And detect the content of heavy metals As, Hg, Cd, Cr, Pb.

Embodiment 2

[0057] A phosphogypsum treatment agent comprises the following components in mass percentage: 93% of calcined phosphorous tailings, 0.8% of ammonium sulfate, 6.2% of solid waste fine powder and 0% of activator. The above-mentioned phosphogypsum treatment agent is used for wet-process phosphoric acid to produce fresh phosphogypsum at the end. 4 3- , F - And detect the content of heavy metals As, Hg, Cd, Cr, Pb.

Embodiment 3

[0059] A phosphogypsum treatment agent, comprising the following components in mass percentage: 95.4% of calcined phosphorus tailings, 0.6% of ammonium sulfate, 4% of solid waste fine powder and 0% of activator. The above-mentioned phosphogypsum treatment agent is used for the new row of phosphogypsum in the storage yard, only harmless treatment, the amount of the treatment agent is 8% of the solid content in the phosphogypsum, and the PO in the phosphogypsum leachate before and after treatment 4 3- , F - And detect the content of heavy metals As, Hg, Cd, Cr, Pb.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com