Preparation method of PDMS sponge-based strain sensor material

A strain sensor and sponge technology, applied in the field of flexible electronic materials, can solve the problems of restricting application and development, failing to meet the urgent needs of high strain sensors, and high manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

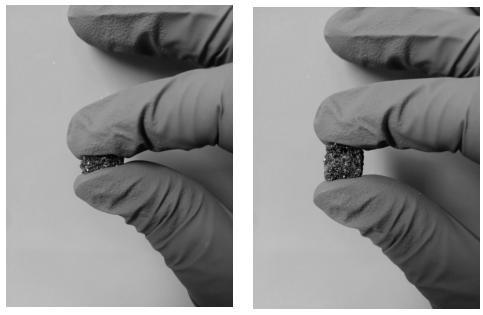

Image

Examples

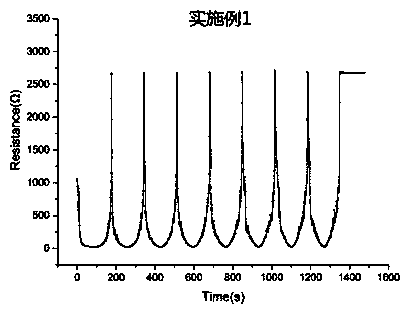

Embodiment 1

[0025] Step (1), weigh 5g each of white granulated sugar and soft white sugar, put them into a beaker and stir evenly, then add 1ml of deionized water to continue stirring, put the stirred sugar into a cube mold with a side length of 1cm, and then put Dry in an oven for 5 hours to obtain cube sugar.

[0026] Step (2): Weigh an appropriate amount of PDMS raw rubber and curing agent in a ratio of 10:1, place in a beaker and stir vigorously for 5 minutes, use ultrasound to remove the bubbles caused by stirring, and then put the sugar cube prepared in step (1) Immerse in it, and put it in a vacuum drying oven to vacuum for 2 hours, then take it out and put it in an oven at 100°C to cure for 1 hour, and finally put the solidified sugar cube in deionized water. After the sugar cube is fully dissolved, dry it. Get PDMS sponge.

[0027] In step (3), first immerse the PDMS sponge prepared in step (2) in 0.2mg / ml acidic chitosan solution and squeeze 5 times, put it in an oven to dry, a...

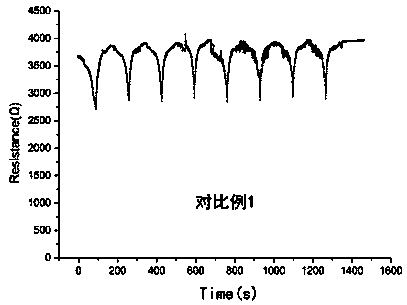

Embodiment 2

[0037] Step (1), weigh 5g each of white granulated sugar and soft white sugar, put them into a beaker and stir evenly, then add 1ml of deionized water to continue stirring, put the stirred sugar into a cube mold with a side length of 1cm, and then put Dry in an oven for 5 hours to obtain cube sugar.

[0038] Step (2): Weigh an appropriate amount of PDMS raw rubber and curing agent in a ratio of 10:1, place in a beaker and stir vigorously for 5 minutes, use ultrasound to remove the bubbles caused by stirring, and then put the sugar cube prepared in step (1) Immerse in it, and put it in a vacuum drying oven to vacuum for 2 hours, then take it out and put it in an oven at 100°C to cure for 1 hour, and finally put the solidified sugar cube in deionized water. After the sugar cube is fully dissolved, dry it. Get PDMS sponge.

[0039]In step (3), first immerse the PDMS sponge prepared in step (2) in 0.2mg / ml acidic chitosan solution and squeeze it 5 times, put it in an oven to dry,...

Embodiment 3

[0042] Step (1), weigh 5g each of white granulated sugar and soft white sugar, put them into a beaker and stir evenly, then add 1ml of deionized water to continue stirring, put the stirred sugar into a cube mold with a side length of 1cm, and then put Dry in an oven for 5 hours to obtain cube sugar.

[0043] Step (2): Weigh an appropriate amount of PDMS raw rubber and curing agent in a ratio of 10:1, place in a beaker and stir vigorously for 5 minutes, use ultrasound to remove the bubbles caused by stirring, and then put the sugar cube prepared in step (1) Immerse in it, and put it in a vacuum drying oven to vacuum for 2 hours, then take it out and put it in an oven at 120°C to cure for 1 hour, and finally put the cured sugar cube in deionized water. After the sugar cube is fully dissolved, dry it. Get PDMS sponge.

[0044] In step (3), first immerse the PDMS sponge prepared in step (2) in 0.4mg / ml acidic chitosan solution and squeeze it 5 times, put it in an oven to dry, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com