Steel for wear-resistant and corrosion-resistant chain plate and manufacturing method thereof

A manufacturing method and corrosion-resistant technology, applied in the field of metal materials, can solve problems such as complex process and low carbon content of 16Mn chain steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

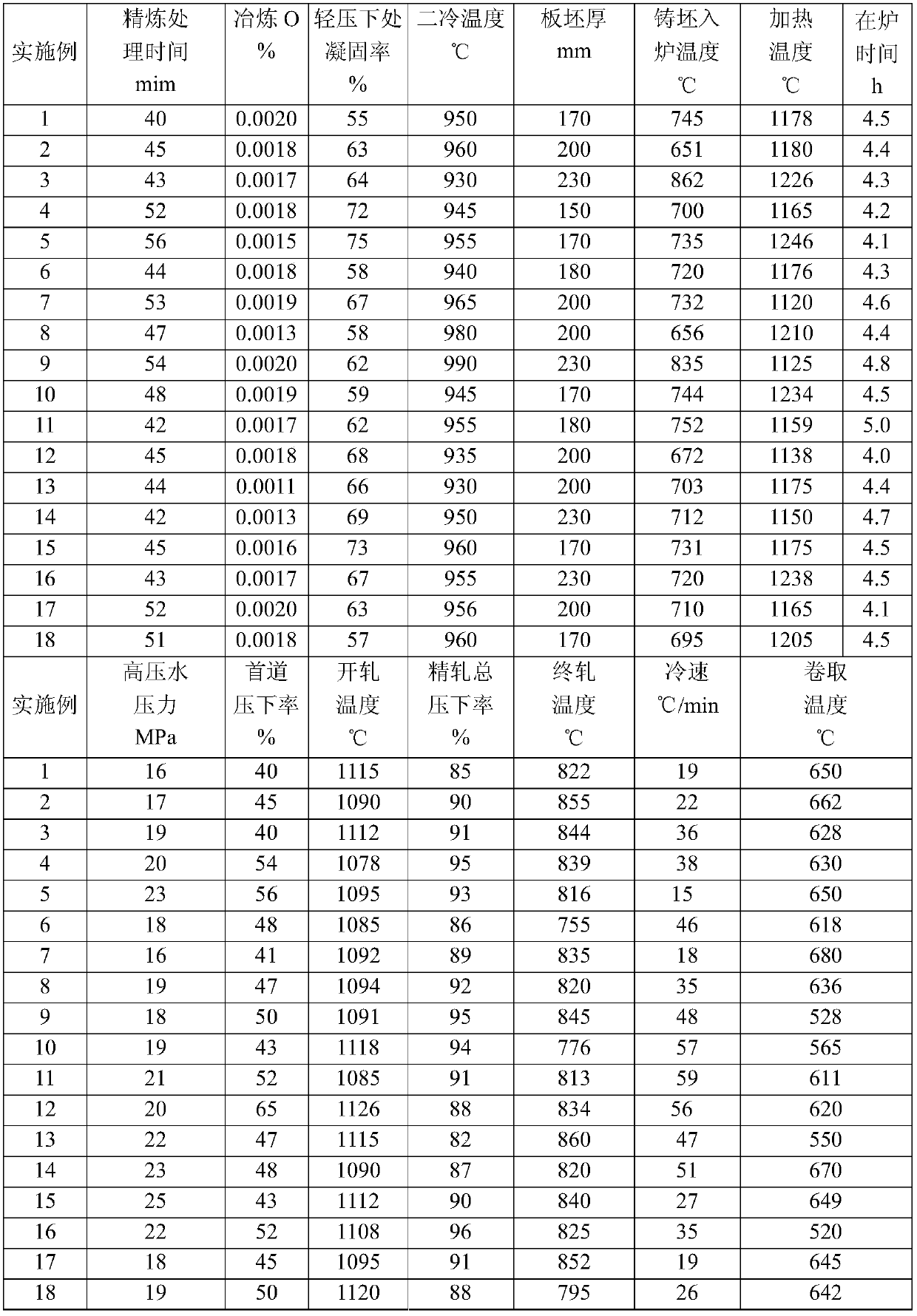

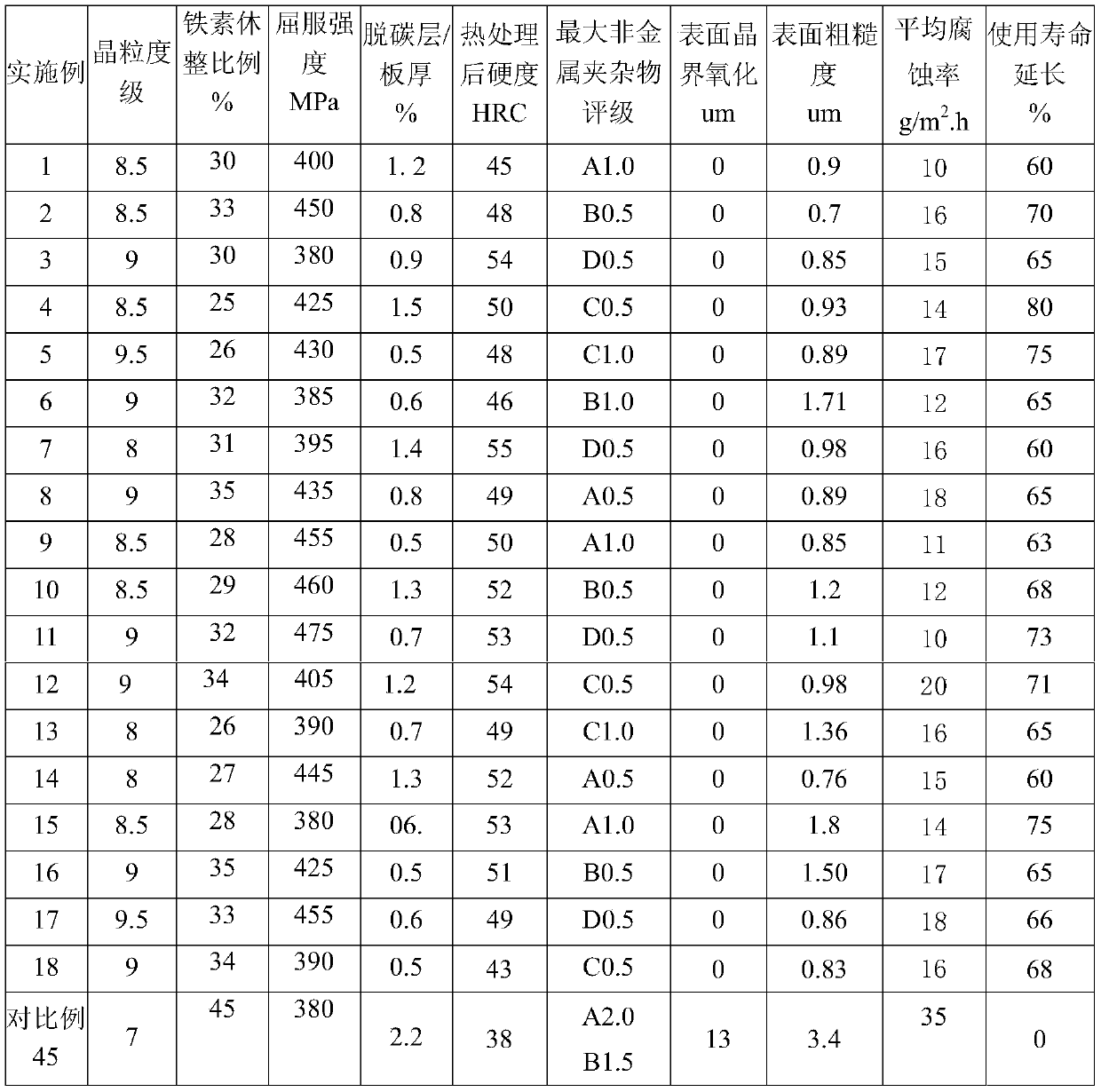

[0048] Below by embodiment the present invention will be further described.

[0049] In the embodiments of the present invention, smelting, continuous casting and rolling of slabs, and hot rolling are carried out according to the composition ratio of the technical proposal.

[0050] (1) Smelting:

[0051] Converter smelting, LF or RH out-of-furnace refining, the refining treatment time is required to be more than 30 minutes, and the intermediate package O≤0.0020% is required to ensure that the finished product O≤0.0015%;

[0052] (2) Slab continuous casting and rolling:

[0053] The solidification rate of the slab is 55-75% and lightly pressed. The thickness of the slab is not more than 230mm. The slab is continuously cast and rolled. After the slab is cut, it does not go down the roller table. Furnace temperature above 700°C.

[0054] (3) Hot rolling process:

[0055] (a) The heating furnace adopts a reducing atmosphere heating furnace, the billet heating temperature is 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com