Preparation method of mosquito-repellent spandex

A technology of spandex and mosquito repellent, which is applied in the fields of rayon manufacturing, fiber chemical characteristics, textiles and paper making, etc. It can solve the problems of poor mosquito repellent effect of mosquito repellent spandex, easy loss of mosquito repellent effect, short lasting effect of mosquito repellent spandex, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

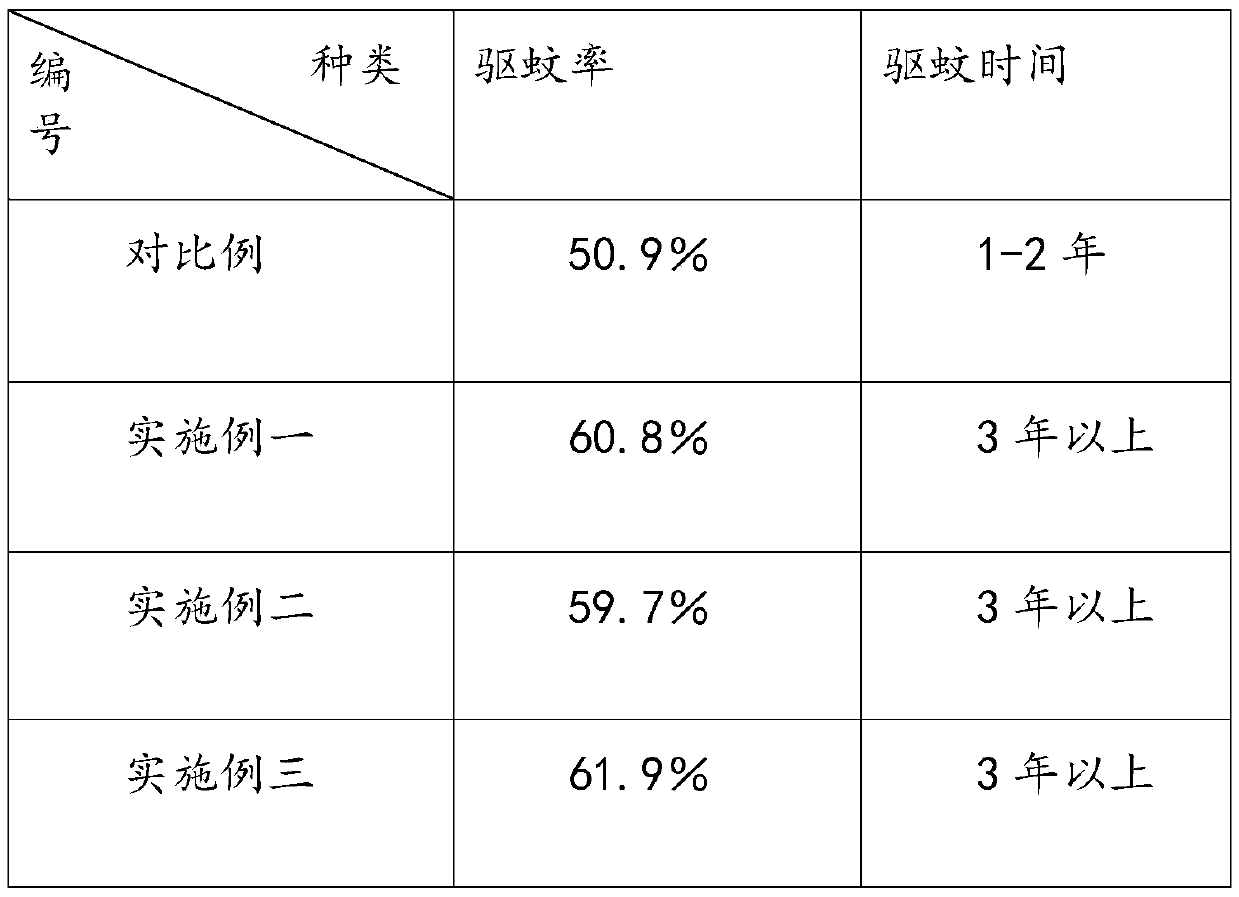

Examples

Embodiment 1

[0027] The embodiment of the present invention provides a method for preparing mosquito repellent spandex. Mosquito repellent spandex is composed of the following raw materials in parts by weight: 100 parts of polytetramethylene ether glycol, 10 parts of 4,4-diphenylmethane diisocyanate, dimethyl 120 parts of acetamide, 20 parts of mint fiber, 12 parts of chain extender, 8 parts of natural bamboo fiber, 8 parts of mosquito repellent, 7 parts of auxiliary agent;

[0028] The mosquito repellent is composed of the following raw materials in parts by weight: 1 part of Nepenthes extract, 2 parts of Tuberose extract, 3 parts of Lavender extract, and 6 parts of Passionia extract;

[0029] The auxiliary agent is composed of the following raw materials in parts by weight: 7 parts of light stabilizer, 5 parts of antioxidant, 3 parts of flame retardant, and 1 part of surfactant;

[0030] Wherein, the mosquito repellent spandex comprises the following preparation steps:

[0031] S1, poly...

Embodiment 2

[0038] The embodiment of the present invention provides a method for preparing mosquito repellent spandex. The mosquito repellent spandex is composed of the following raw materials in parts by weight: 110 parts of polytetramethylene ether glycol, 11 parts of 4,4-diphenylmethane diisocyanate, dimethyl 140 parts of acetamide, 25 parts of mint fiber, 14 parts of chain extender, 10 parts of natural bamboo fiber, 9 parts of mosquito repellent, and 8 parts of auxiliary agent;

[0039] The mosquito repellent is composed of the following raw materials in parts by weight: 2 parts of Nepenthes extract, 3 parts of Tuberose extract, 4 parts of Lavender extract, and 8 parts of Passiflora extract;

[0040] The auxiliary agent is composed of the following raw materials in parts by weight: 8 parts of light stabilizer, 6 parts of antioxidant, 4 parts of flame retardant, and 1.5 parts of surfactant;

[0041] Wherein, the mosquito repellent spandex comprises the following preparation steps:

[...

Embodiment 3

[0048] The embodiment of the present invention provides a method for preparing mosquito repellent spandex. Mosquito repellent spandex is composed of the following raw materials in parts by weight: 120 parts of polytetramethylene ether glycol, 12 parts of 4,4-diphenylmethane diisocyanate, dimethyl 160 parts of acetamide, 30 parts of mint fiber, 16 parts of chain extender, 12 parts of natural bamboo fiber, 10 parts of mosquito repellent, 9 parts of auxiliary agent;

[0049]The mosquito repellent is composed of the following raw materials in parts by weight: 3 parts of Nepenthes extract, 4 parts of Tuberose extract, 5 parts of Lavender extract, and 10 parts of Passiflora extract;

[0050] The auxiliary agent is composed of the following raw materials in parts by weight: 9 parts of light stabilizer, 7 parts of antioxidant, 5 parts of flame retardant, and 2 parts of surfactant;

[0051] Wherein, the mosquito repellent spandex comprises the following preparation steps:

[0052] S1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com