Method for curing nano pattern structure under assistance of electromagnetic waves

A nano-pattern and electromagnetic wave technology, which is applied in nanotechnology, circuits, electrical components, etc., can solve problems such as large losses, difficulty in completely removing moisture from nano-pattern structures, and collapse of nano-patterns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

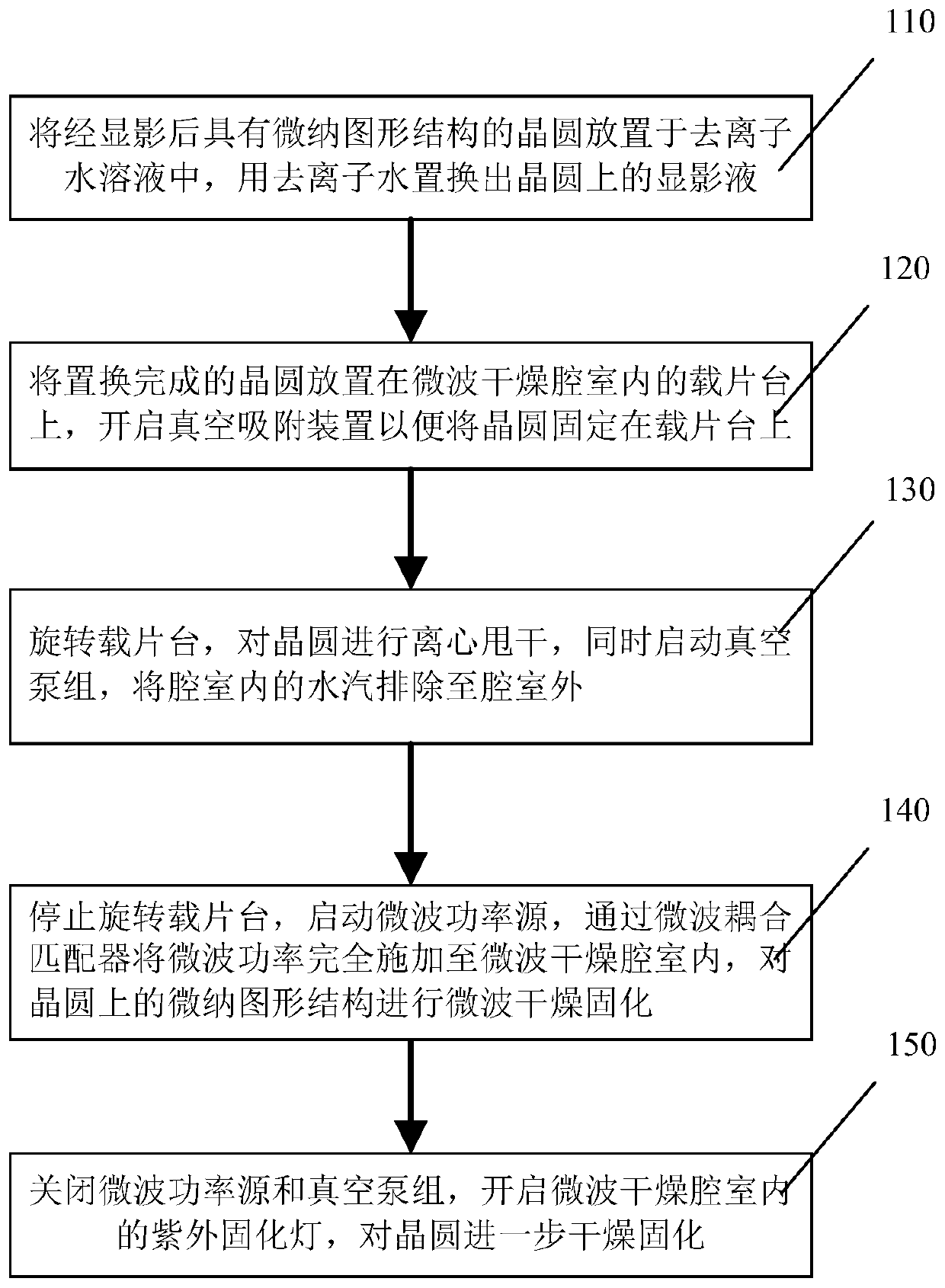

Image

Examples

Embodiment Construction

[0022] In order to better understand the above-mentioned technical solution, the above-mentioned technical solution will be described in detail below in conjunction with the accompanying drawings and specific implementation methods.

[0023] First, briefly describe the basic physical principle of drying using electromagnetic waves. Since water is a polar molecule, polar molecules do not show polarity when there is no external electromagnetic field. Under the condition of an external alternating electromagnetic field, the water molecules will be rapidly polarized, and the stronger the external alternating electromagnetic field, the stronger the polarization. At this time, the kinetic energy of the molecular thermal motion increases, that is, the heat increases, and the temperature of the water also increases, realizing the conversion of electromagnetic energy into heat energy. Therefore, water molecules can absorb electromagnetic waves and convert the energy of electromagnetic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com