Chip package

A chip packaging and chip technology, applied in electrical components, electrical solid devices, circuits, etc., can solve the problems of increasing the PCBA processing process and the difficulty of QFN repair.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

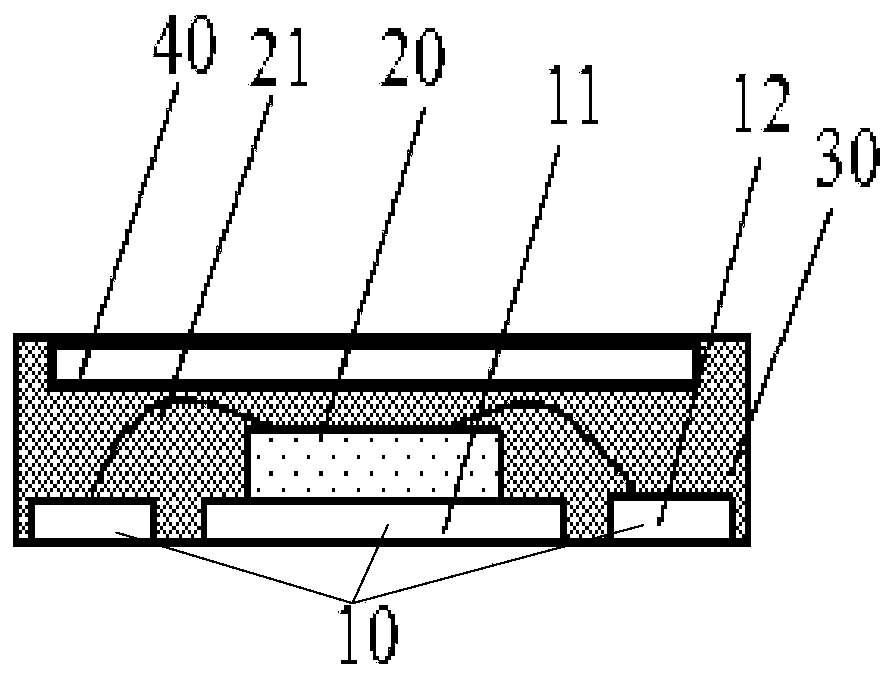

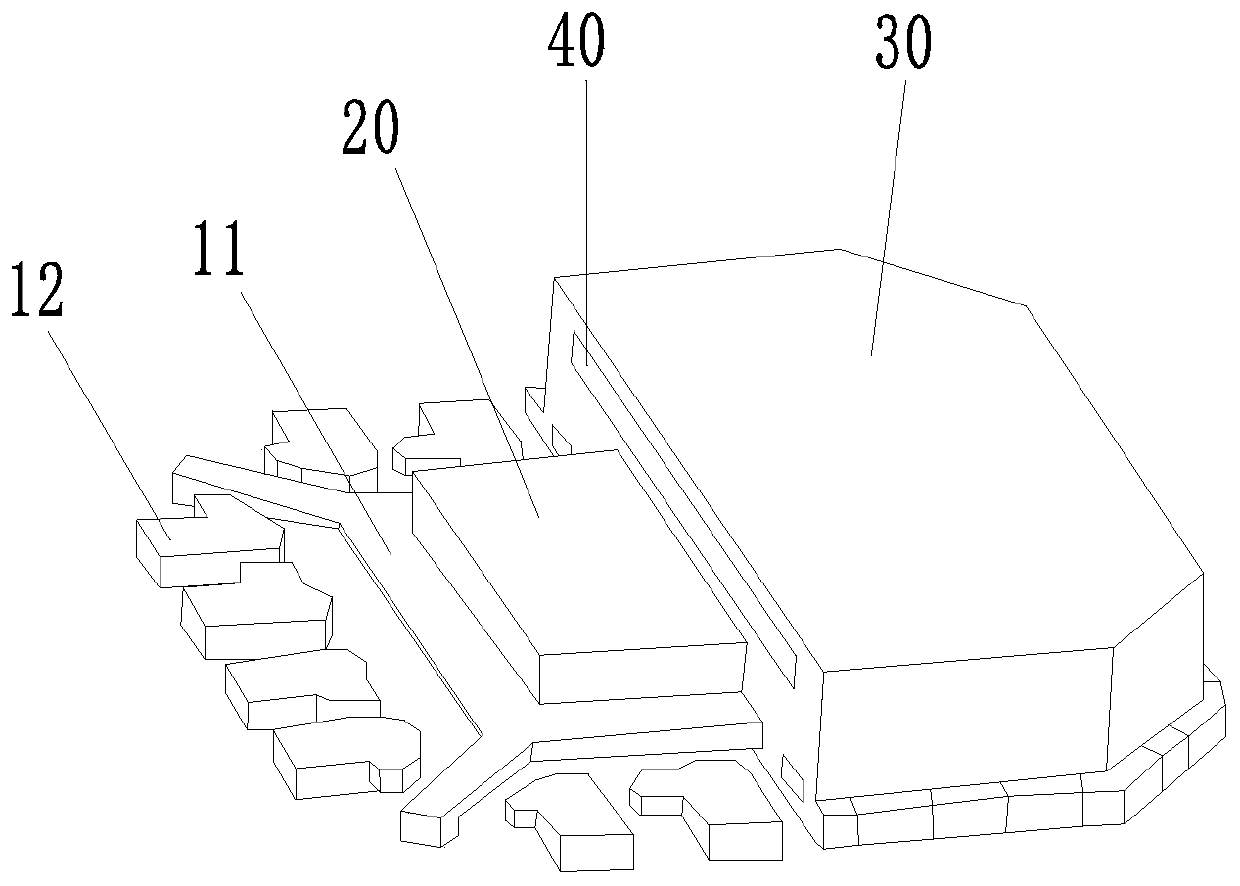

[0053] Such as image 3 As shown, a chip package is provided, including a pad 10, a chip 20, a package body 30 and a thermally deformable member 40, and the pad 10 includes a heat dissipation pad 11 and electrode contact pads arranged around the heat dissipation pad 11 12; the chip 20 is attached to the upper surface of the heat dissipation pad 11, and is electrically connected to the electrode contact pad 12; the package body 30 covers the sealing pad 10 and the chip 20, and the lower surface of the pad 10 is exposed to the package body 30 Surface; the thermally deformable member 40 is thermally deformed when heated, and is disposed on the package body 30 , and the thermally deformable member 40 and the bonding pad 10 are respectively disposed on two sides of the chip 20 .

[0054] In this example, if image 3 As shown, the thermally deformable member 40 is completely encapsulated inside the package body 30 . The chip 20 is selected as a silicon chip, which is connected to ...

Embodiment 2

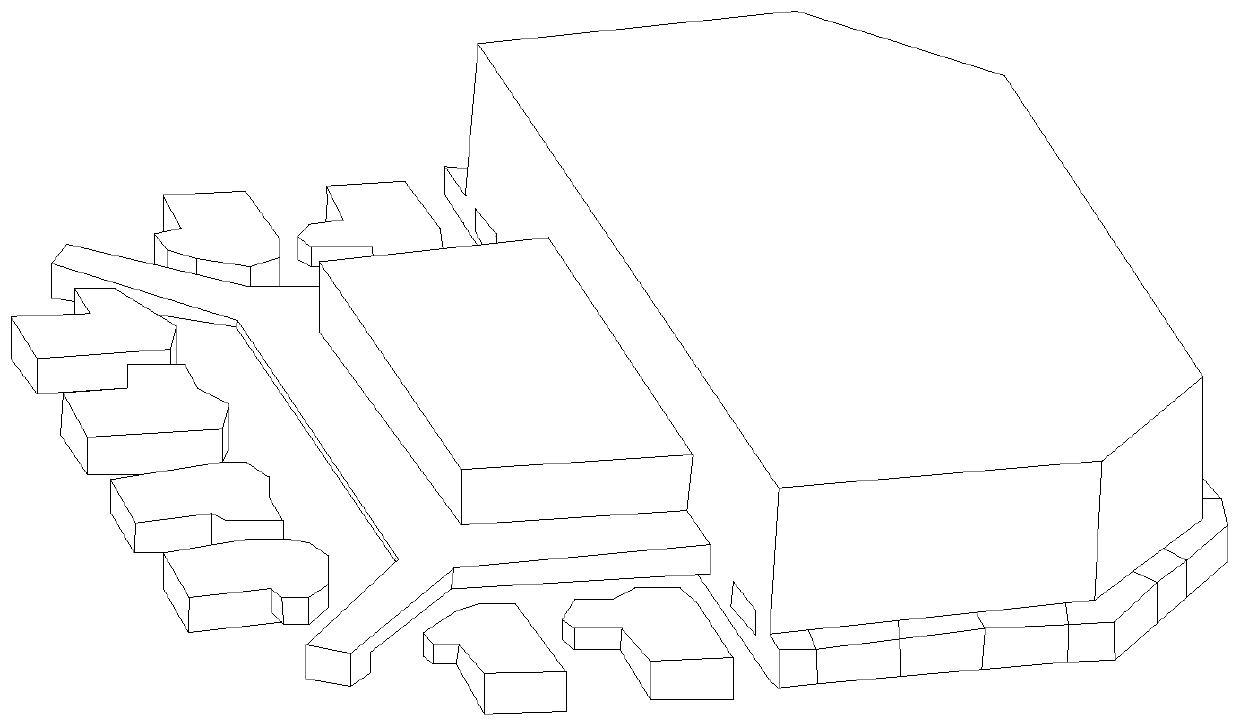

[0057] Such as Figure 4 As shown, a chip package is provided, including a pad 10, a chip 20, a package body 30 and a thermally deformable member 40, and the pad 10 includes a heat dissipation pad 11 and electrode contact pads arranged around the heat dissipation pad 11 12; the chip 20 is attached to the upper surface of the heat dissipation pad 11, and is electrically connected to the electrode contact pad 12; the package body 30 covers the sealing pad 10 and the chip 20, and the lower surface of the pad 10 is exposed to the package body 30 Surface; the thermally deformable member 40 is thermally deformed when heated, and is disposed on the package body 30 , and the thermally deformable member 40 and the bonding pad 10 are respectively disposed on two sides of the chip 20 .

[0058] In this example, if Figure 4 As shown, the thermally deformable member 40 of this embodiment is disposed outside the package body 30 . The chip 20 is selected as a silicon chip, which is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com