Assembled modular multi-layer pig raising device

A modular and assembled technology, applied in the field of animal breeding, can solve the problems of increasing the load and difficulty of wastewater treatment, high manure treatment costs, and difficult economic benefits, so as to reduce the cost of manure treatment, improve centralized breeding, reduce The effect of construction investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

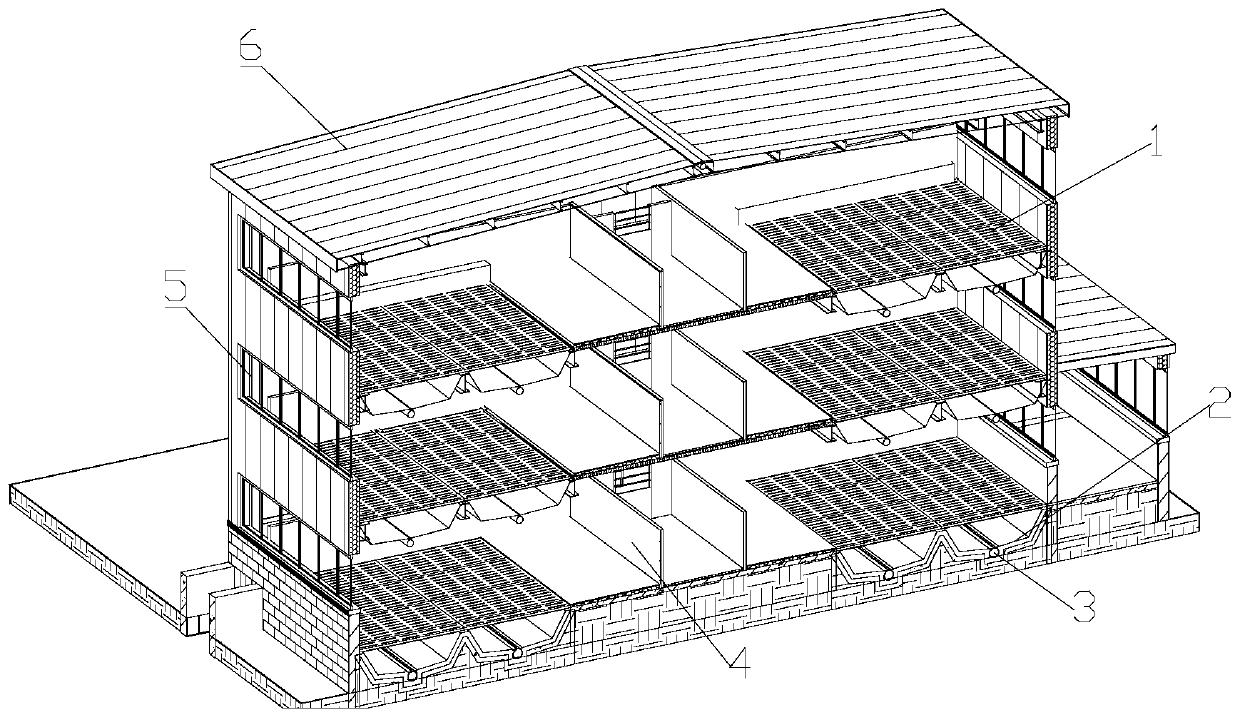

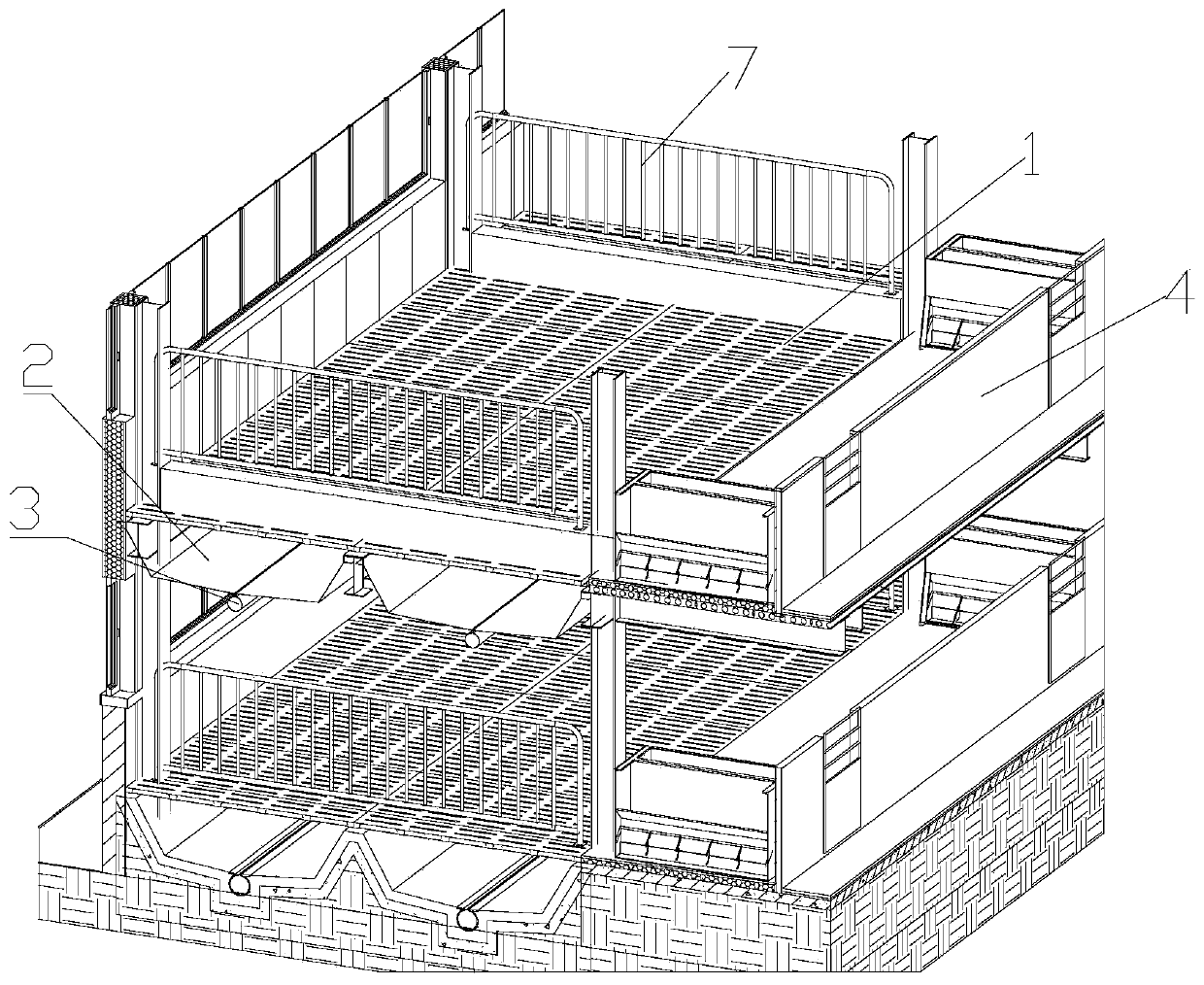

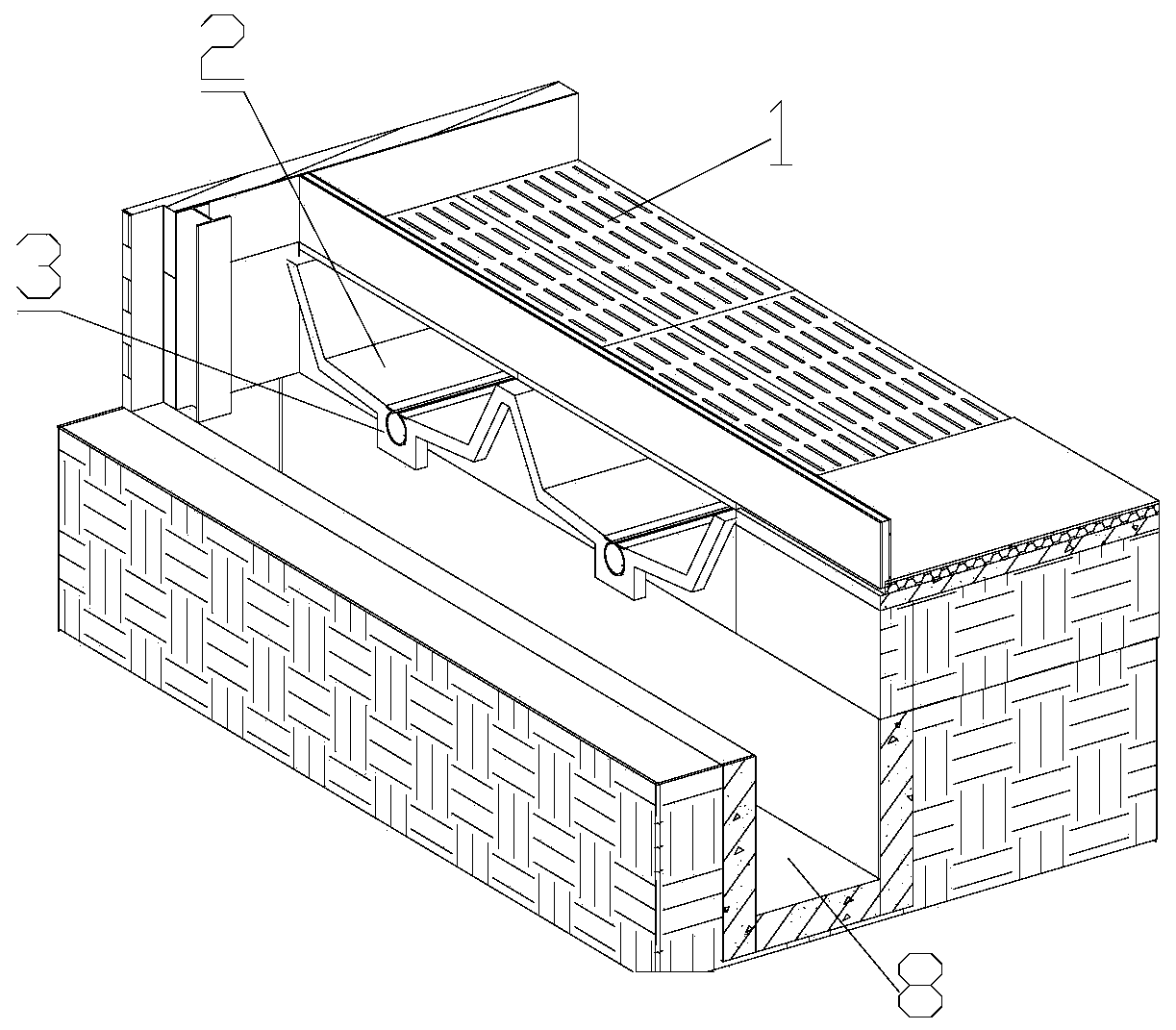

[0068] Such as figure 1 , figure 2 and image 3 As shown, an assembled modularized multi-layer pig raising equipment includes a multi-layer pig house beam structure, a multi-layer feeding layer, a feces collection and separation device, a urine collection pipe and a gutter 8 .

[0069] Wherein, the beam structure includes: vertical load-bearing beams 17, horizontal load-bearing beams 18, fences 4, longitudinal beams 19, pedestrian walkways 20 and pedestrian walkway load-bearing beams 21.

[0070] Such as Figure 8 As shown, four vertical load-bearing beams 17 are vertically fixed on the foundation, and a horizontal load-bearing beam 18 is welded between every two adjacent vertical load-bearing beams 17, and the horizontal load-bearing beam 18 is perpendicular to the vertical load-bearing beam 17, The space surrounded by four vertical load-bearing beams 17 and the horizontal load-bearing beams 18 corresponds to a breeding area, and the feeding layer is located in the breedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com