Bamboo-plastic composite board hot press and hot press process

A composite board and hot press technology, applied in the direction of coating, etc., can solve the problems of high equipment requirements, easy dry cracking and delamination, and high processing costs, and achieve the effects of low equipment requirements, reduced production costs, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

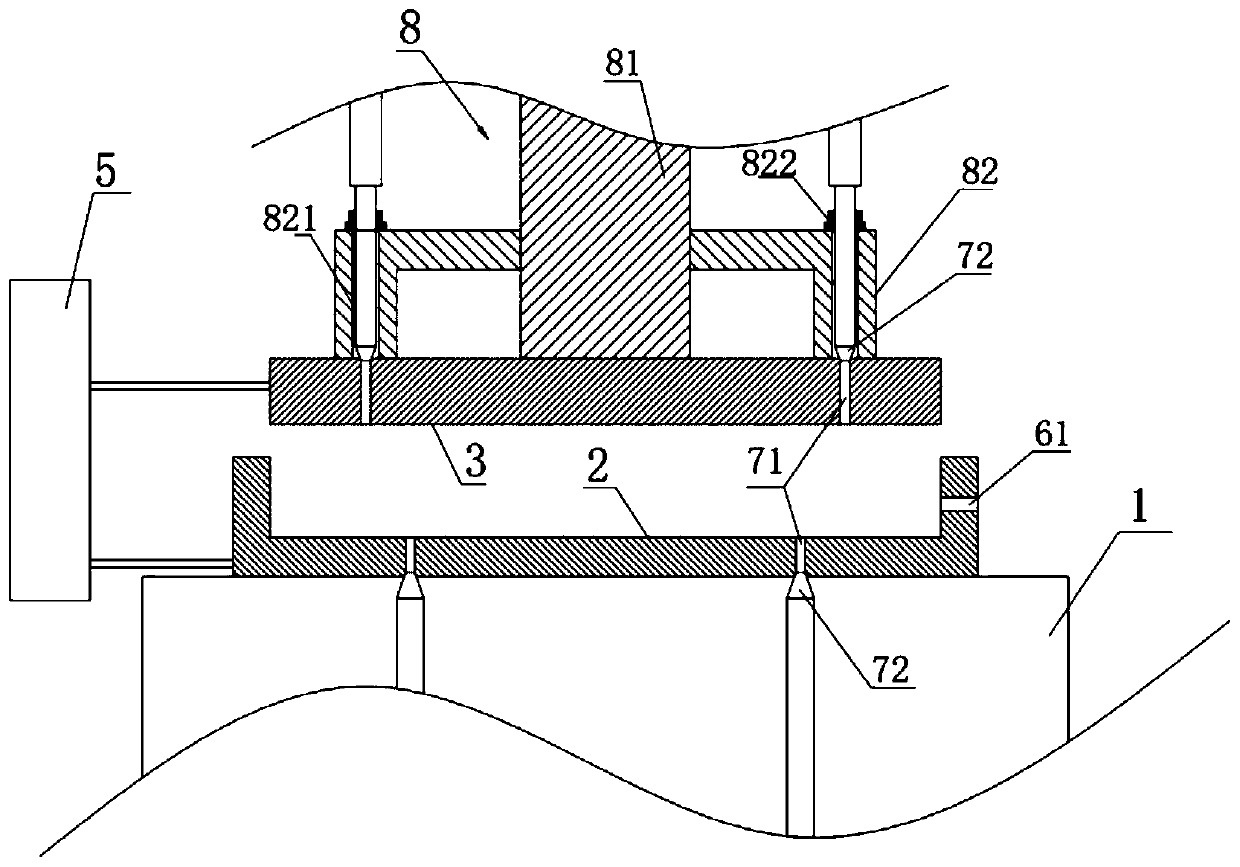

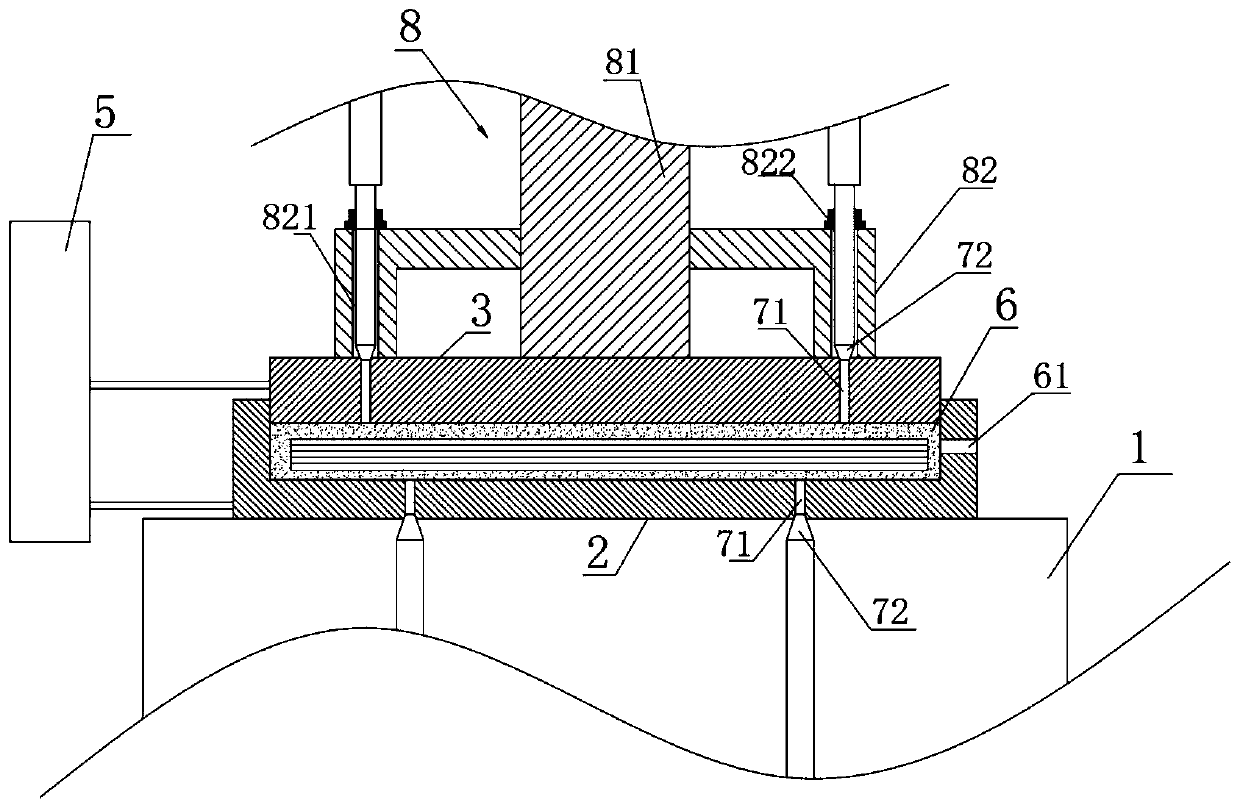

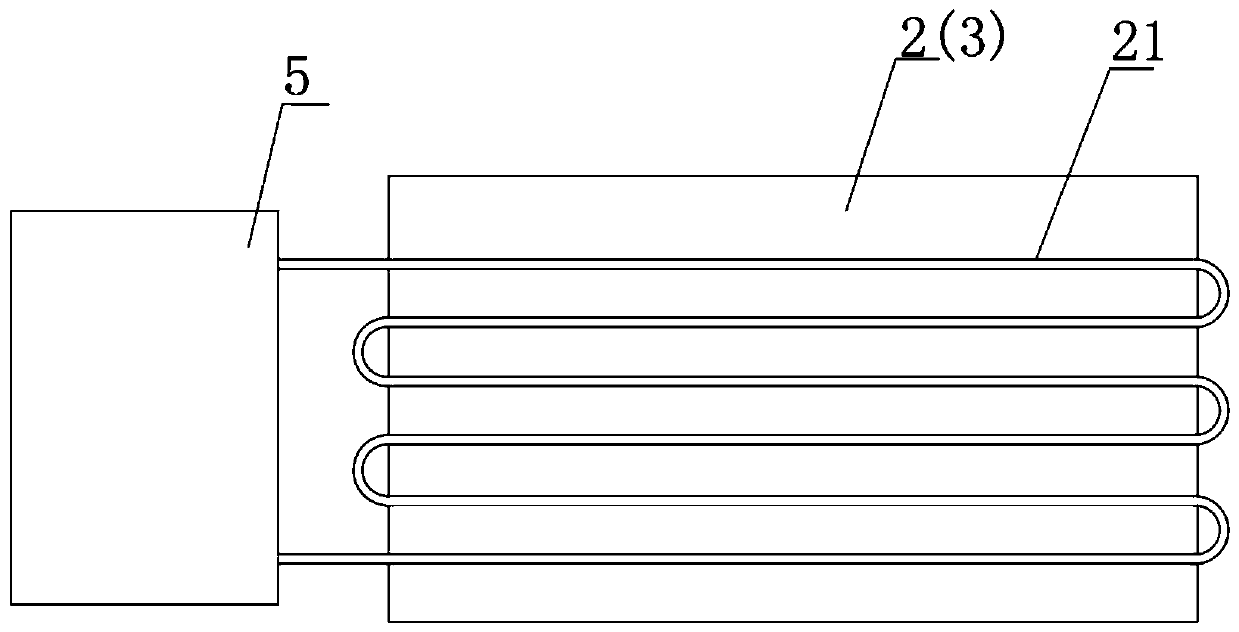

[0035] see Figures 1 to 4 , a bamboo-plastic composite board hot press, comprising a support 1, a bottom mold 2 fixedly installed on the support 1, a pressing plate 3, a hydraulic device for driving the pressing plate 3 to lift, and providing heat or cooling for the pressing plate 3 and the bottom mold 2 The temperature control device 5; when the pressure plate 3 is pressed into the bottom mold 2, the bottom mold 2 and the pressure plate 3 are enclosed into a sealed hot-pressed space 6; an openable air inlet 61 communicates with the hot-pressed space 6, to the said The hot-pressing space 6 is filled with pressurized gas; the bottom mold 2 and the pressure plate 3 are respectively provided with an injection device 7; the bottom mold 2 and the pressure plate 3 are respectively provided with an injection port 71; the injection molding device 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com