Forming extrusion equipment for pok plastic rods

A technology of extrusion equipment and plastic rods, which is applied in the field of pok plastic rod forming extrusion equipment, can solve the problems that the wear resistance and impact resistance cannot meet the processing requirements, so as to enhance the wear resistance and impact resistance, increase the The effect of improving the service life and molding conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

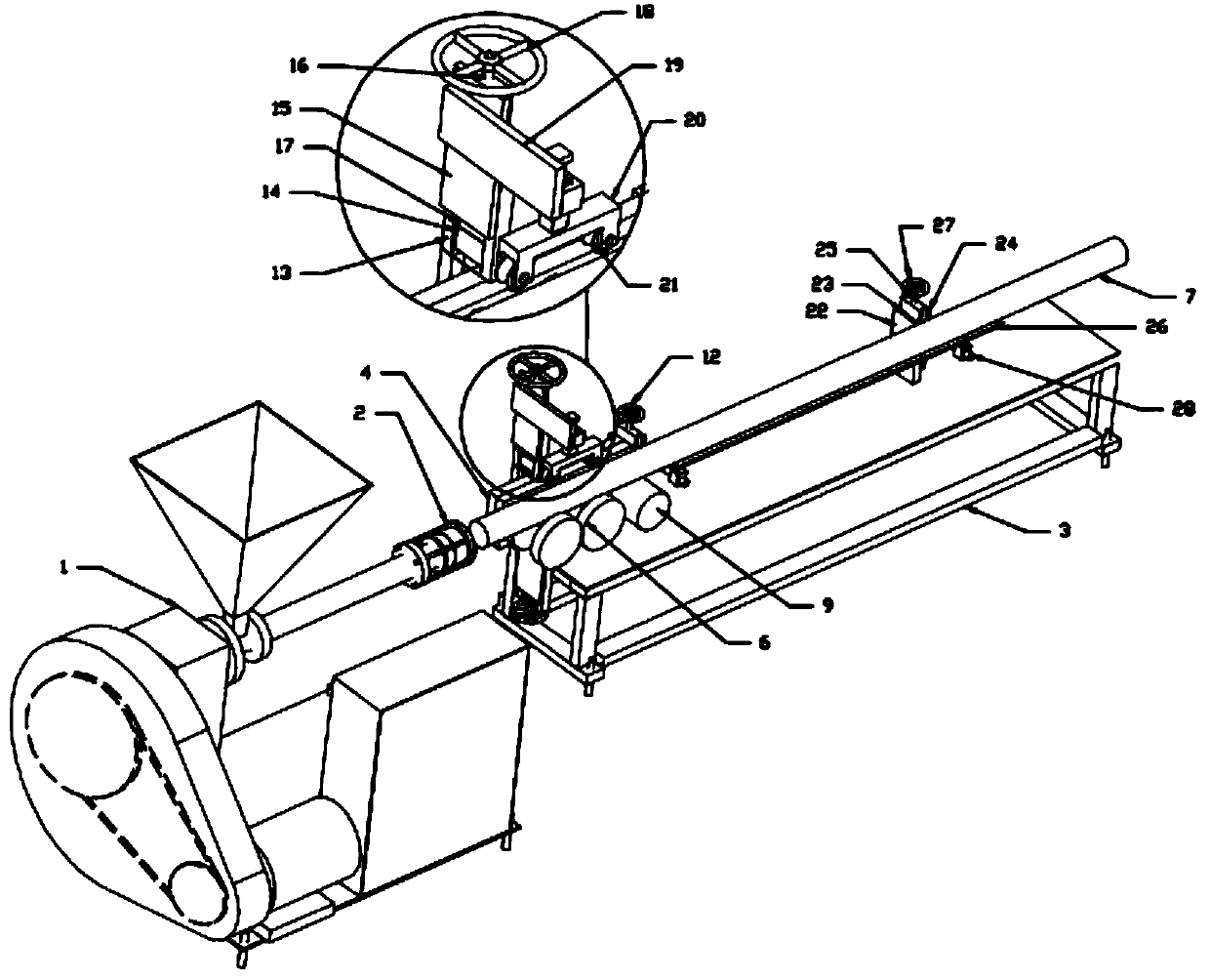

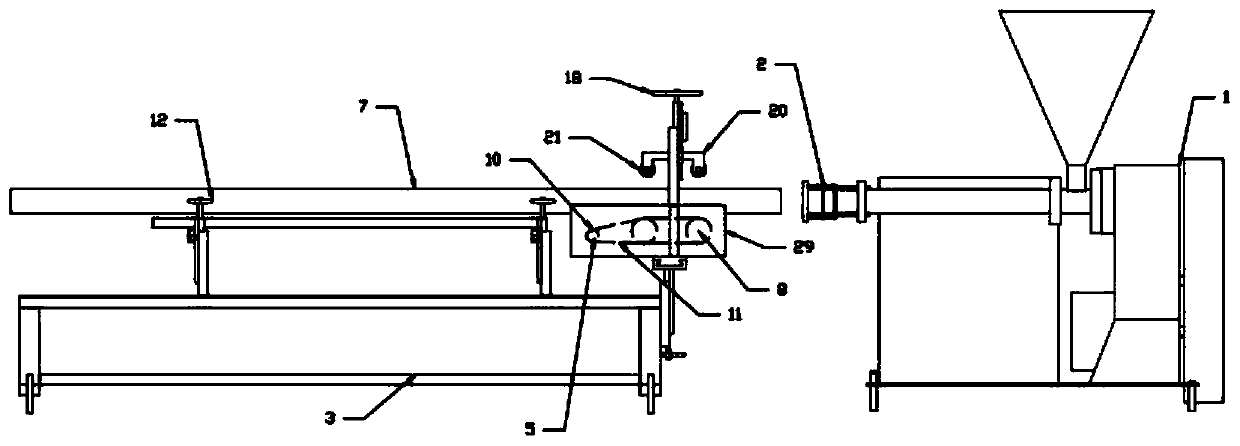

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0014] combined with figure 1 , figure 2 , pok plastic rod molding extrusion equipment, including an extruder 1, the extruder 1 is connected with an extruder head 2, and one side of the extruder 1 is provided with a working Table 3, the side of the workbench 3 close to the extruder head 2 is provided with a fixed plate 4, and one side of the fixed plate 4 is rotatably connected with two connecting shafts 5, and the connecting shaft 5 extends out of the fixed plate 4 One end is all socketed with a U-shaped wheel-6, and a bar 7 is arranged on the U-shaped wheel-6, and the other end of the connecting shaft 5 extending out of the fixed plate 4 is all socketed with a gear-8. The fixed plate 4 is provided with a variable speed motor 9 near the side of the U-shaped wheel one 6, and the output end of the variable speed motor 9 extends out of the fixed plate 4. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com