Carriage plate and preparation method thereof

A technology for car panels and panel layers, applied to chemical instruments and methods, vehicle parts, and upper structures of trucks, etc., can solve the problems of lowering the mechanical properties of the overall car panels, low bonding strength, and low bonding strength, and achieve Increase the aesthetics, shorten the molding cycle, and improve the mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

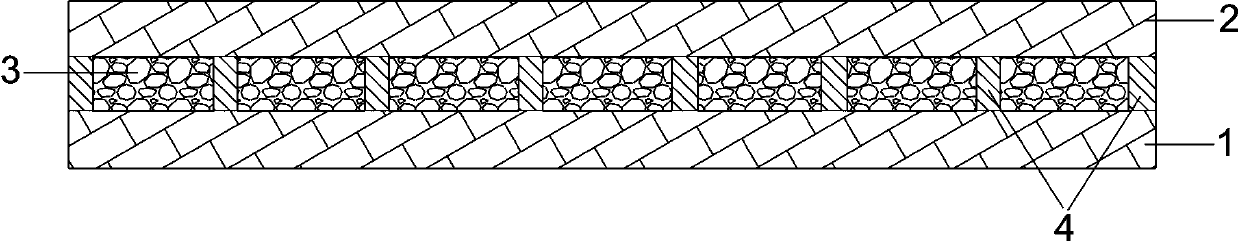

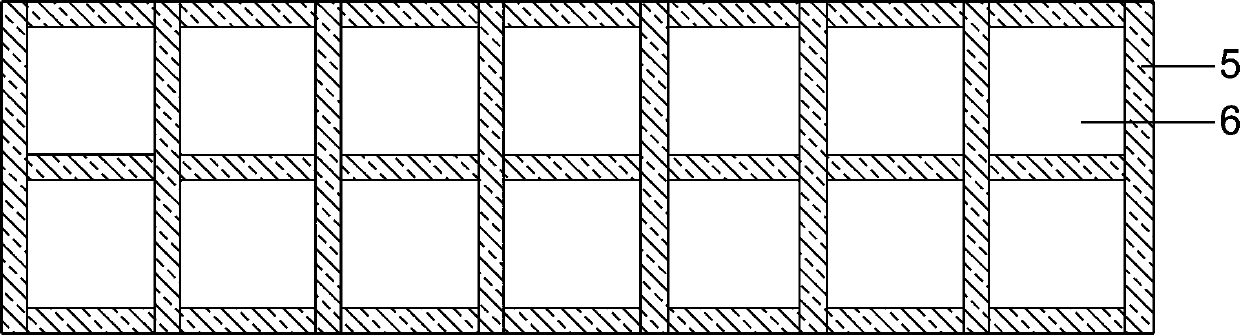

[0033] Such as figure 1 As shown, a compartment panel includes a first panel layer 1, a second panel 2, a sandwich layer, and a skeleton support layer 4, and the sandwich layer is arranged between the first panel layer 1 and the second panel 2, sandwiching The core layer includes several foam blocks 3, the skeleton support layer 4 is grid-shaped (the grid shape is a regular quadrilateral), and the skeleton support layer 4 is arranged between the first panel layer 4 and the second panel layer 4, and the foam block 3 Filling in the grid of the skeleton support layer 4, the skeleton support layer 4 is integrally solidified with the first panel layer 1 and the second panel 2;

[0034] The first panel layer 1, the second panel 2 and the skeleton support layer 4 are glass fiber reinforced unsaturated polyester composite materials; the foam block 3 is a PVC foam block; the thickness of the first panel layer 1 is 1.2 mm, The thickness of the second panel 2 is 1.2 mm, and the thicknes...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com