Long-pin bent plate chain

A bending plate chain and bending chain technology, applied in the field of transmission chain, can solve the problems of large fluctuation of working conditions, unsuitable chain, large carbon content in slag, etc. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

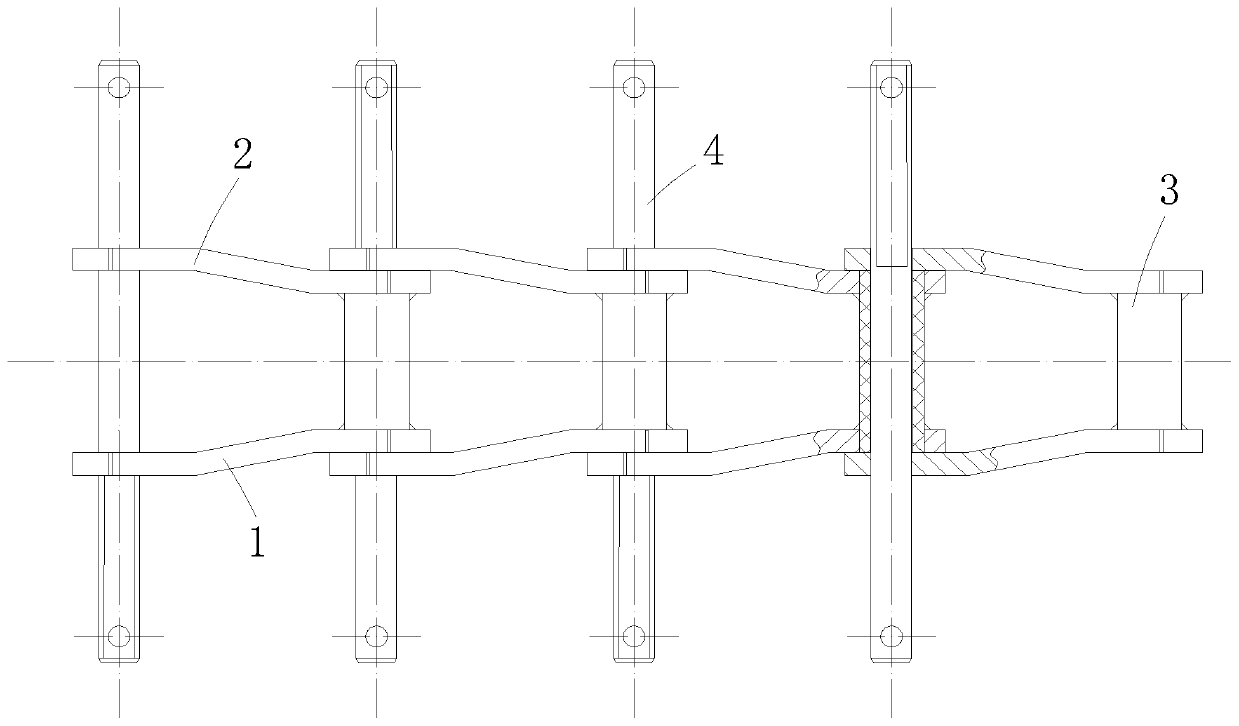

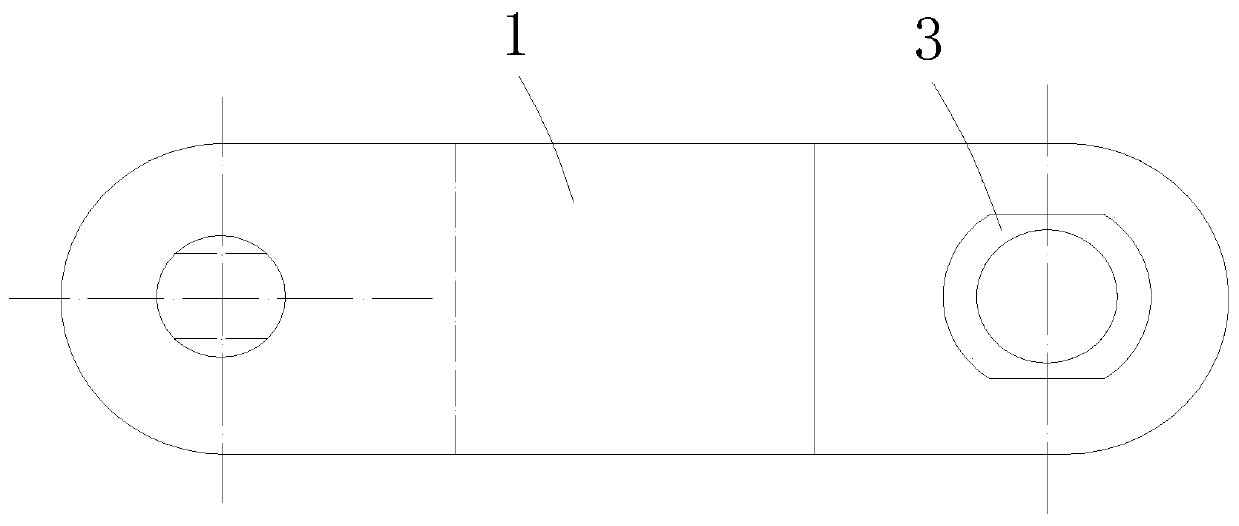

[0035] A long pin bent plate chain, comprising a set of series-connected chain links, each of the chain links includes a round hole bent link plate 1, a flat hole bent link plate 2, a sleeve 3 and a long pin shaft 4;

[0036] In this embodiment, such as Figure 1-3 As shown, the round hole bent chain plate 1 and the flat hole bent chain plate 2 are plate bodies of the same specification, and the round hole bent chain plate 1 and the flat hole bent chain plate 2 are symmetrically arranged. The plate body of the hole-bending chain plate 2 is bent outwards on the same side, and the end of the bending portion is provided with an outer sleeve portion arranged parallel to the plate body, and the outer sleeve portion of the round hole curved chain plate 1 A round pin hole 101 is opened in the middle, and a flat pin hole 201 is opened in the middle of the outer sleeve part of the flat-hole bent chain plate 2;

[0037] The round hole curved chain plate 1 and the flat hole curved chain plate...

Embodiment 2

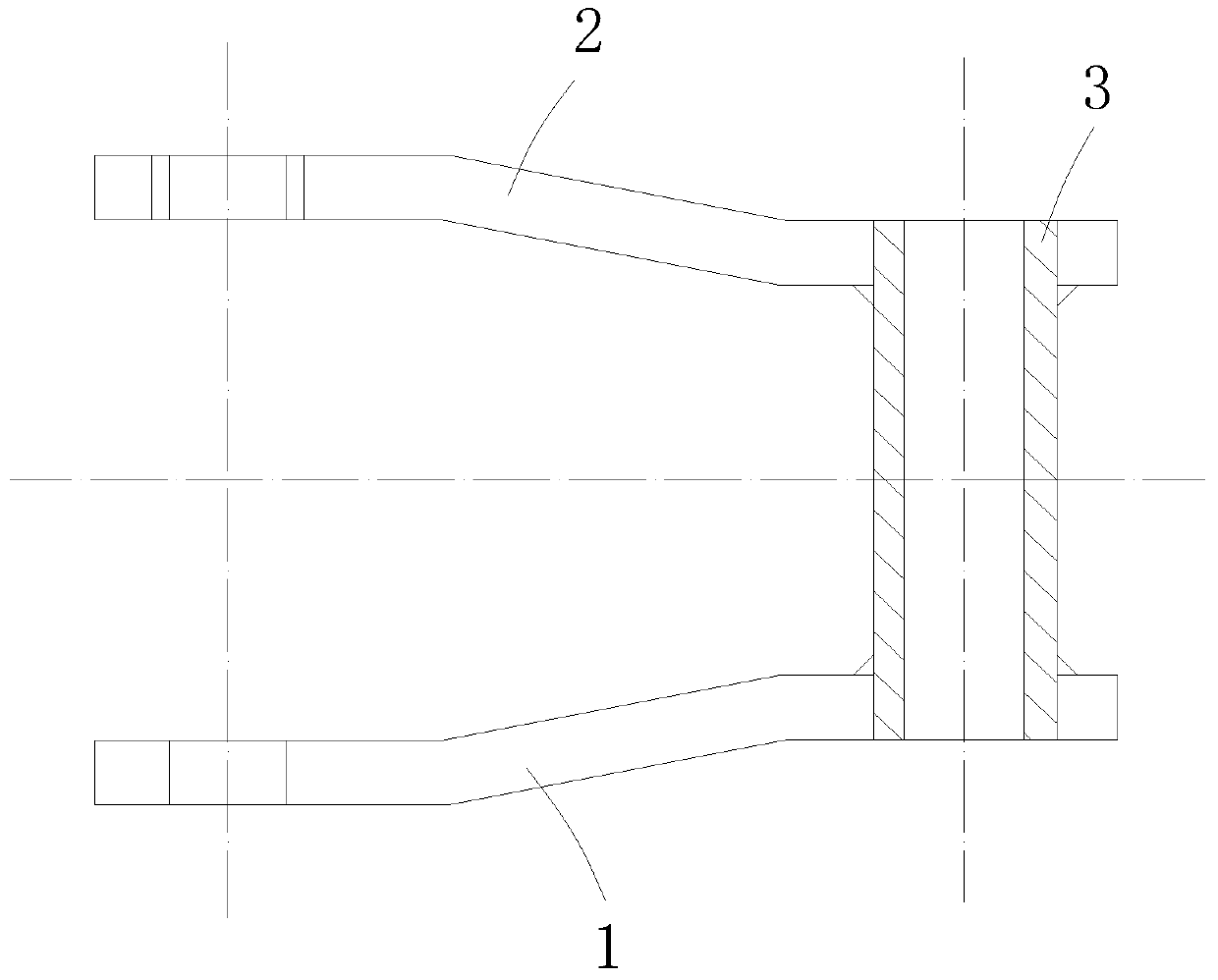

[0046] The difference between this embodiment and embodiment 1 lies in figure 1 , 4 As shown in -6, the side wall of one end of the long pin shaft 4 is integrally formed with a flat end 401 that is symmetrically recessed inward, and the flat end 401 is matched and inserted into the flat pin hole 201, and the flat end 401 prevents the pin from rotating The role of.

[0047] In this embodiment, such as Figure 6-7 As shown, the flat surface of the flat end 401 is cut inward to 1 / 5-1 / 4 of the cross-sectional radius of the long pin shaft 4, and the long pin shaft 4 passes through the link frame to connect the chain. The flat end 401 is cut into The depth limitation effectively prevents the rotation of the pin shaft.

[0048] Refer to Embodiment 1 for other undescribed structures.

[0049] According to the long-pin bent plate chain of the above-mentioned embodiment of the present invention, the round hole bent link plate 1 and the flat hole bent link plate 2 are connected in a staggered...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com