Reflective hot-melt marking coating and construction method thereof

A technology of hot-melt marking paint and marking paint, which is applied in the direction of reflection/signal paint, polyester paint, polyether paint, etc. Poor performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

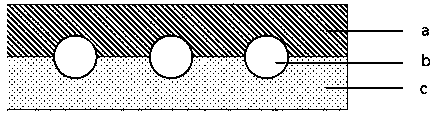

Method used

Image

Examples

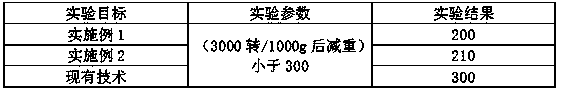

Embodiment 1

[0030] Prepare ingredients:

[0031] Surface layer raw materials: 5 parts of hydroxymethyl cellulose, 5 parts of nitrocellulose, 12 parts of acrylic resin, 8 parts of ethyl cellosolve acetate, 0.8 parts of polyethylene wax; put the above materials into a hot melting furnace, 180 melts at 100 degrees Celsius,

[0032] Bottom layer raw materials: 13 parts of titanium dioxide, 12 parts of petroleum resin, 1.5 parts of plasticizer, 1.4 parts of EVA, 8 parts of PLA-PEG, 3 parts of flake alumina; after mixing the above raw materials evenly, add them to the melting furnace, 220 Melt at Celsius;

[0033] 15 parts of glass beads: the particle size is 30-60 mesh, and the roundness rate is greater than 70%.

[0034] Specific construction:

[0035] Clean the pavement, keep it free of litter, and use a primer to level the pavement so it's smooth and pothole-free. Draw construction lines.

[0036] Draw the hot-melt bottom layer material along the construction line with a thickness of a...

Embodiment 2

[0040] Prepare raw materials

[0041] Surface layer raw materials: 6 parts of hydroxymethyl cellulose, 6 parts of nitrocellulose, 15 parts of acrylic resin, 10 parts of ethyl cellosolve acetate, 1 part of polyethylene wax; put the above raw materials into a hot melting furnace, 180 melts at 100 degrees Celsius,

[0042] Bottom layer raw materials: 15 parts of titanium dioxide, 20 parts of petroleum resin, 1.5 parts of plasticizer, 1.5 parts of EVA, 8 parts of PLA-PEG, 3 parts of flaky alumina; after mixing the above raw materials evenly, add them to the melting furnace, 220 Melt at Celsius;

[0043] 10 parts of glass beads: the particle size is 30-60 mesh, and the roundness rate is greater than 70%.

[0044] Specific construction:

[0045] Clean the pavement, keep it free of litter, and use a primer to level the pavement so it's smooth and pothole-free. Draw construction lines.

[0046] Draw the hot-melt bottom layer material along the construction line with a thickness o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com