Hard surface cleaning composition containing waterborne polyurethane dispersion and preparation method thereof

A water-based polyurethane, hard surface cleaning technology, applied in the directions of surface-active detergent compositions, organic cleaning compositions, detergent compositions, etc., can solve the problems of low film thickness, low polymer addition, not easy to peel, etc. Increased gloss, reduced additive, environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0070] Preparation of aqueous polyurethane dispersion:

[0071] Waterborne Polyurethane Dispersion-1:

[0072] Will 60 grams IPDI (S1), 150 g PPG2000 (S2), 18 g castor oil (S4), 72 g Ymer TM N120 (S3), 0.09 g of BiCat8108 (S9), 96 g of acetone (S7) were added into a four-neck flask with a thermometer and a stirring rod, heated to 70°C for 5 hours, then cooled to 40°C, and 192 g of acetone ( S7), then add 437 grams of water (S8) under high-speed stirring (1200r / min), add the mixture of 3.2 grams of EDA (S5) and 10 grams of water (S8) after the dispersion ends, continue to stir for 5min, slough acetone, get The particle size is 80nm, and the solid content is 40.4% nonionic polyurethane dispersion-1. The polyoxyethylene chain segment accounts for 24% by weight of the water-based polyurethane solids, and R is 1.57.

[0073] Waterborne Polyurethane Dispersion-2:

[0074] Will 120 grams IPDI (S1), 90 g PPG1000 (S2), 24 g castor oil (S4), 66 g Ymer TM N120 (S3), 0.09 g of Bi...

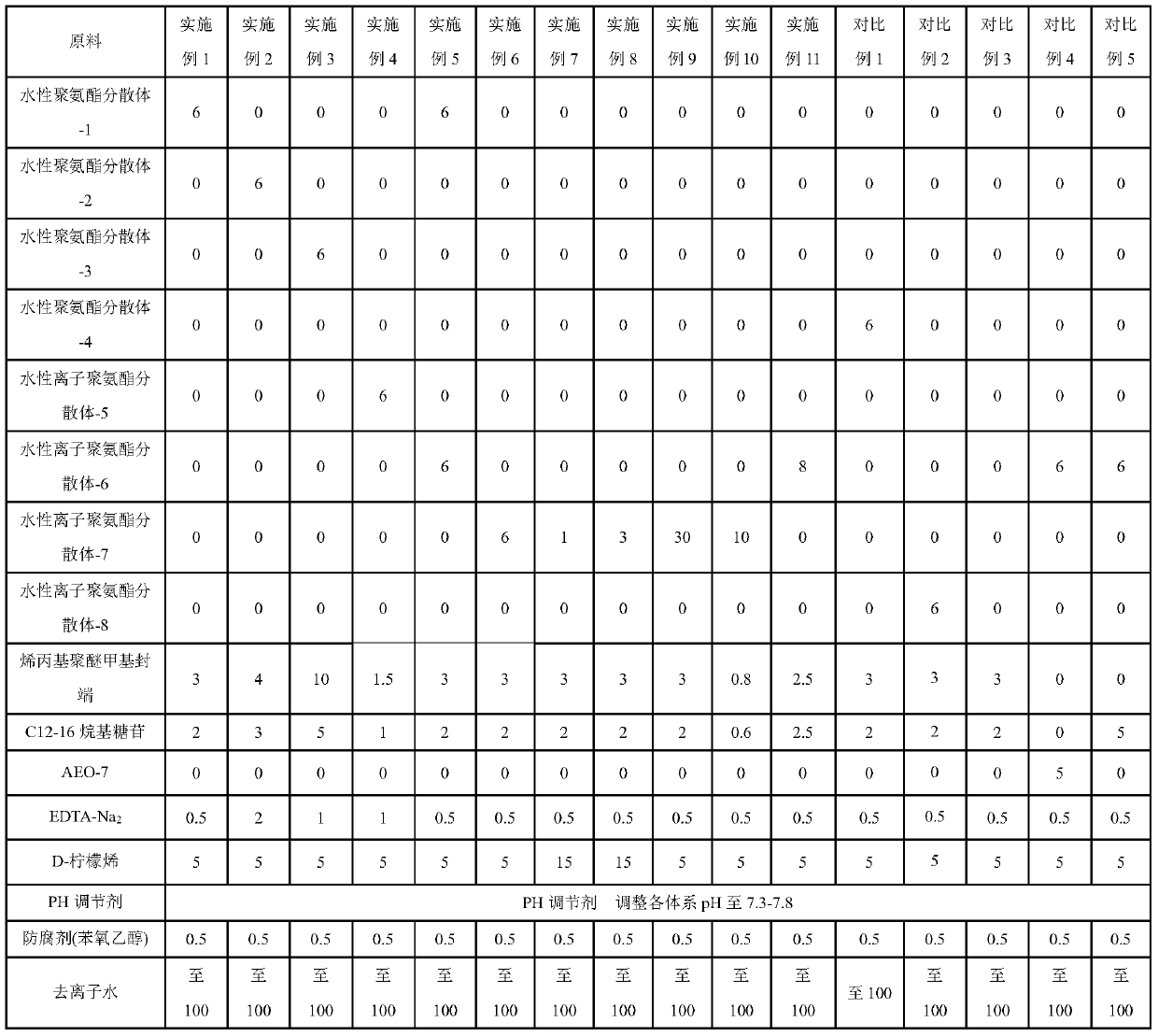

Embodiment 1-11、 comparative example 1-5

[0088] The hard surface cleaner compositions of Examples 1-11 and Comparative Examples 1-5 were prepared according to the proportions of the components shown in Table 1. Among them, APG1214 was selected for C12-16 alkyl glycosides in Examples 1-6, Comparative Examples 1, 3, and 4, and APG1216 was selected for C12-16 alkyl glycosides in Examples 7-11, Comparative Examples 2 and 5.

[0089] Concrete formula is as shown in table 1 (weight part) as follows:

[0090] Table 1: Formulation Composition

[0091]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com