A high-precision large-flow multi-way valve with disturbance compensation

A disturbance compensation, high-precision technology, applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problem of limiting the flow capacity of the main valve, reduce the compensation pressure difference, improve flow control accuracy and control Stability, the effect of improving control stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

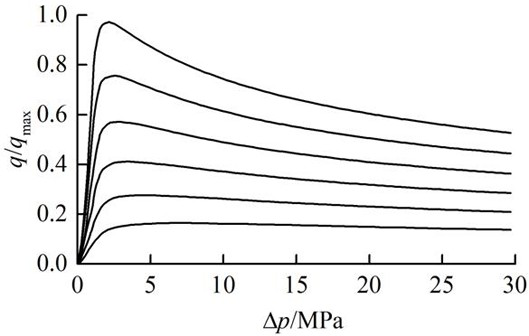

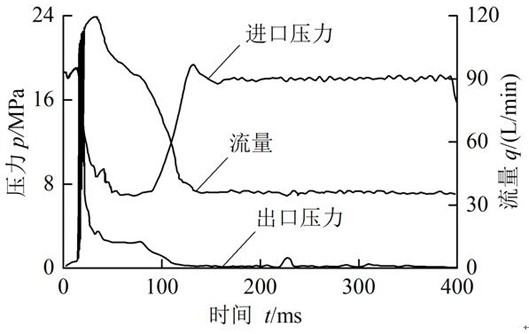

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] like Figure 7 As shown, a high-precision and large-flow multi-way valve with disturbance compensation includes main oil circuit 1, return oil circuit 2, reversing valve 3, pilot control type differential pressure compensator 4, shuttle valve 5, load sensing oil circuit 6. Wherein, the reversing valve 3 is an electronic proportional reversing valve as shown in the figure, and may also be one of a hydraulically controlled reversing valve and an electro-hydraulic proportional reversing valve.

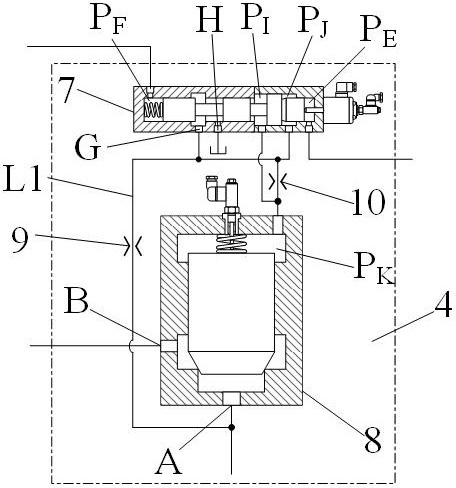

[0037] like image 3 As shown, the pilot control type differential pressure compensator 4 includes a pilot compensator 7 , a main valve 8 , a first damping hole 9 and a second damping hole 10 .

[0038] like Figure 4 , 5As shown, the pilot compensator 7 includes the left valve body 11, the right valve body 12, the pilot compensator spool 13, the compensator spring 14, the proportional electromagnet 15, the first displacement sensor 16, the first control chamber P E , the secon...

Embodiment 2

[0047] like Figure 8 As shown, a high-precision and large-flow multi-way valve with disturbance compensation includes the first valve group 26 and the tail valve group 28. The two valve groups share a unified main oil circuit 1, return oil circuit 2 and load-sensitive oil circuit. 6. Each valve group includes a reversing valve 3, a pilot-controlled differential pressure compensator 4, and a shuttle valve 5. The reversing valve 3 is an electronic proportional reversing valve as shown in the figure, and it can also be a hydraulic control reversing valve. One of valves and electro-hydraulic proportional directional valves.

[0048] like image 3 As shown, the pilot control type differential pressure compensator 4 includes a pilot compensator 7 , a main valve 8 , a first damping hole 9 and a second damping hole 10 .

[0049] like Figure 4 , 5 As shown, the pilot compensator 7 includes the left valve body 11, the right valve body 12, the pilot compensator spool 13, the compen...

Embodiment 3

[0059] like Figure 9 As shown, compared with Embodiment 2, an intermediate valve group 27 is added between the first valve group 26 and the tail valve group 28, and the oil inlet on the side of the shuttle valve in the first valve group 26 and the intermediate valve group 27 It is connected to the oil outlet of the shuttle valve in the next valve group, and the oil inlet on one side of the shuttle valve in the tail valve group 28 is connected to the fuel tank.

[0060] When the number of valve groups is further increased, including the first valve group, the tail valve group and some intermediate valve groups, the connection mode of the shuttle valve in each valve group is the same as that of the first valve group 26, the middle valve group 27, The tail valve group 28 is the same.

[0061] like Figure 10 As shown, when the pilot control type differential pressure compensator 4 is set in front of the valve, the pilot compensator 7 is normally open, that is, the pilot compen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com