Shell, manufacturing method of shell and household appliance

A shell and body technology, applied in the field of home appliances, can solve the problems of poor appearance of the door body and irregular traces left on the appearance of the door body, etc., and achieve the effects of reducing the input of materials and manpower, improving the appearance quality, and being convenient to operate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

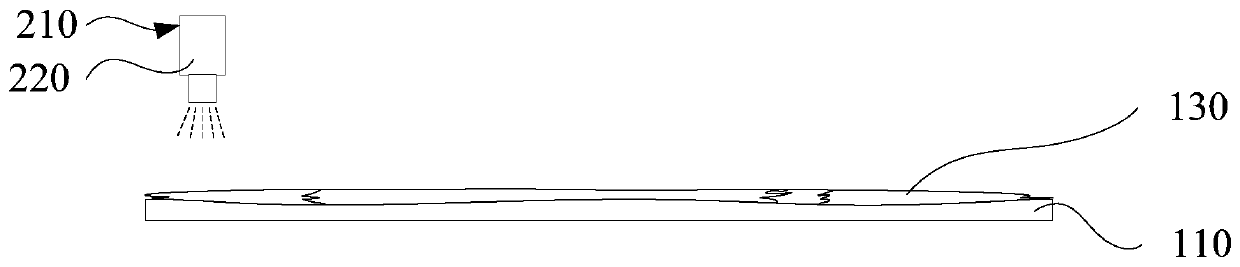

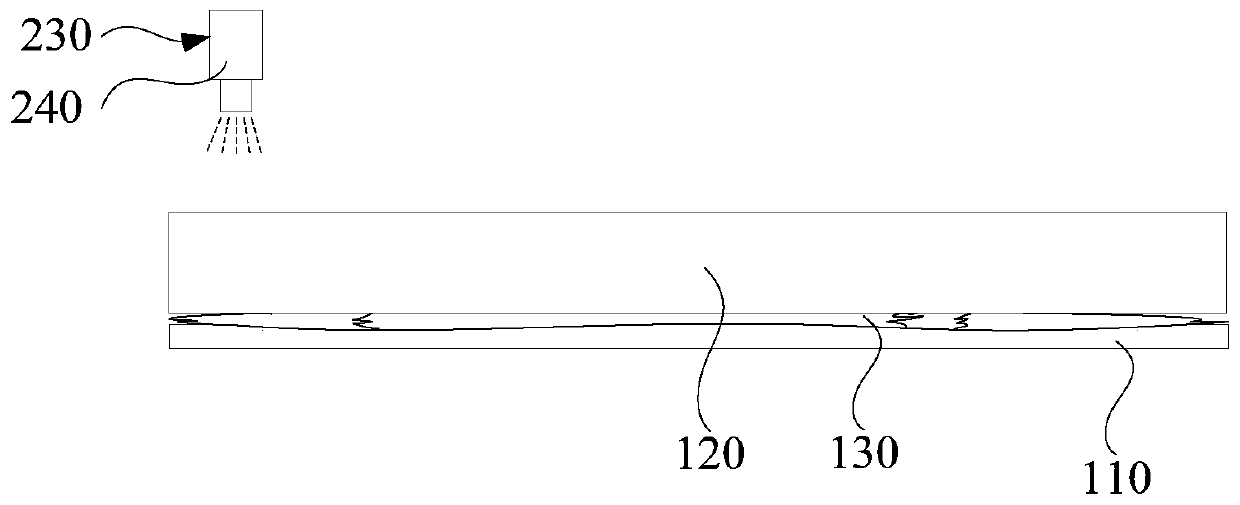

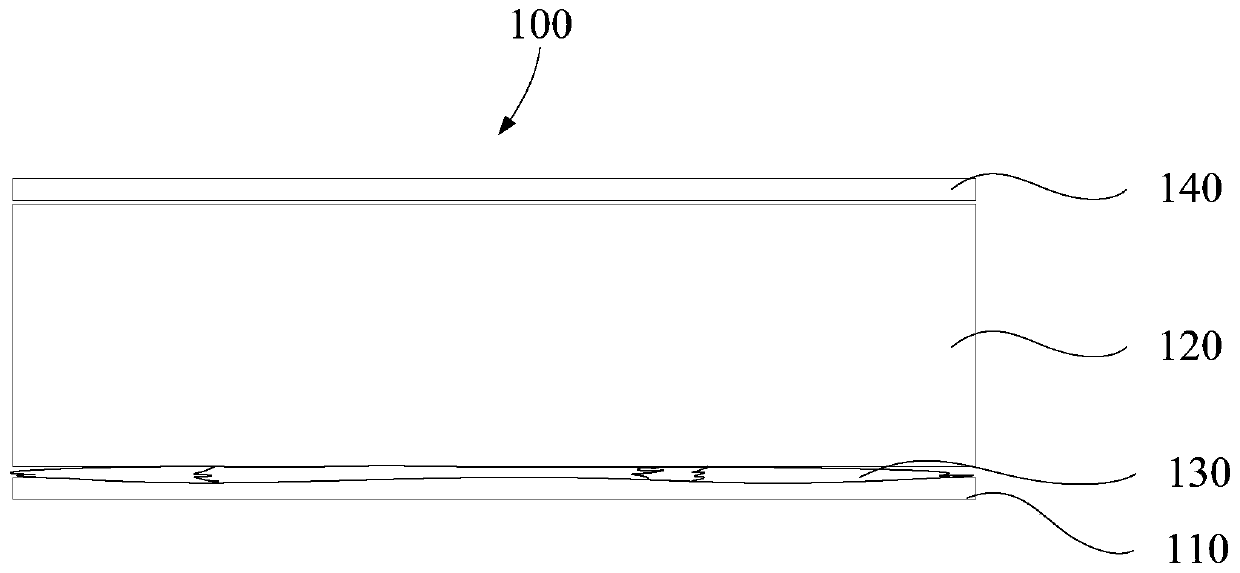

[0086] Such as Figure 1 to Figure 3 As shown, the embodiment of the first aspect of the present invention proposes a casing 100, including: a body 110, a first foam layer 120, and an isolation layer 130, wherein the first foam layer 120 and the body 110 are integrated by foaming Forming, the isolation layer 130 is disposed between the body 110 and the first foam layer 120 , and the adhesion of the material of the isolation layer 130 is greater than the adhesion of the material of the first foam layer 120 .

[0087] Specifically, such as figure 2 with image 3 As shown, the first foam layer 120 and the body 110 are integrally formed by foaming, the isolation layer 130 is arranged between the body 110 and the first foam layer 120, and the adhesion of the material of the isolation layer 130 is greater than that of the first foam layer The adhesion of the material of 120 makes the isolation layer 130 and the body 110 have higher adhesion, which can avoid the direct contact bet...

Embodiment 2

[0089] Such as Figure 1 to Figure 3 As shown, in one embodiment of the present invention, the casing 100 includes a body 110, a first foam layer 120 and an isolation layer 130, wherein the isolation layer 130 is a second foam layer or coating.

[0090] In this example, if figure 1 with figure 2 As shown, on the one hand, the isolation layer 130 is the second foam layer, that is, the isolation layer 130 and the body 110 are integrally formed by foaming. Specifically, after the isolation layer 130 and the body 110 are integrally formed by foaming, an isolation layer The main body 110 and the first foam layer 120 of 130 are integrally formed through foaming again; The main body 110 of the layer and the first foam layer 120 are integrally formed by foaming, and the different structures of the isolation layer 130 can meet the requirements of different processing techniques of the isolation layer 130, and at the same time, can meet the requirements of different materials of the ...

Embodiment 3

[0096] Such as Figure 1 to Figure 3 As shown, in an embodiment of the present invention, on the basis of the above-mentioned embodiment 2, further, the material components of the isolation layer 130 include: polyether polyol, 1,4-butanediol, foaming catalyst, silicone oil , water, toluene diisocyanate, curing catalyst, trimerization catalyst.

[0097]In this embodiment, the material components of the isolation layer 130 include polyether polyol, 1,4-butanediol, foaming catalyst, silicone oil, water, toluene diisocyanate, curing catalyst, and trimerization catalyst. The material composition of layer 130 makes the isolation layer 130 formed be flexible polyurethane foam, and flexible polyurethane foam has higher adhesive force, meanwhile, flexible polyurethane foam is mostly open cell structure, and resilience is good, makes isolation layer 130 There is no air bubble between the body 110 and the isolation layer 130 itself does not shrink after curing, thereby ensuring a high a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com