Fluid temperature field analysis method for double-pipe buried pipe heat exchanger

A buried tube heat exchanger and fluid temperature technology, applied in indirect heat exchangers, geothermal collectors, geothermal energy, etc., can solve the problem of ignoring the heat capacity of boreholes and the unsteady heat transfer of boreholes, and the calculation of three-dimensional numerical models complex process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

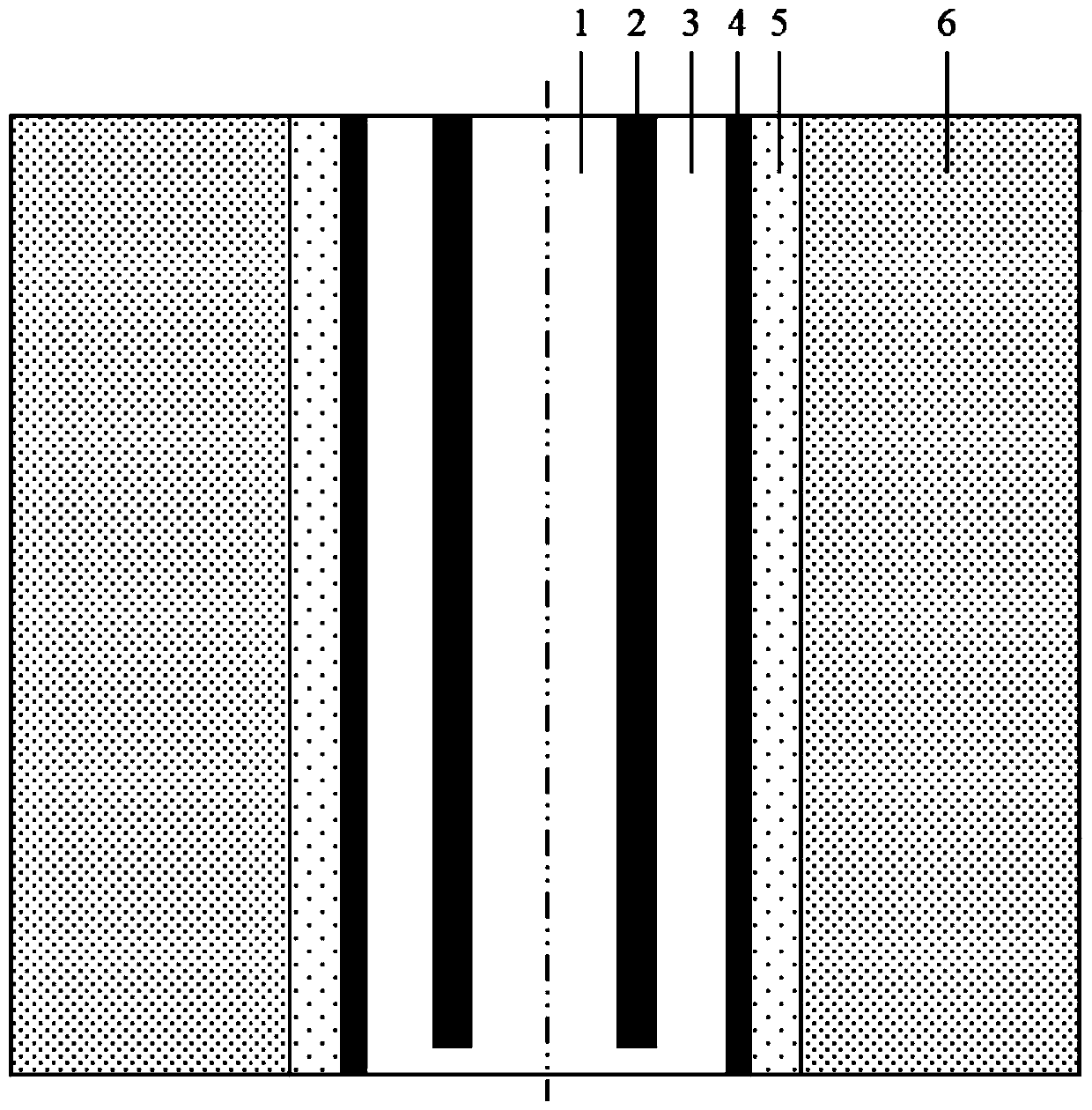

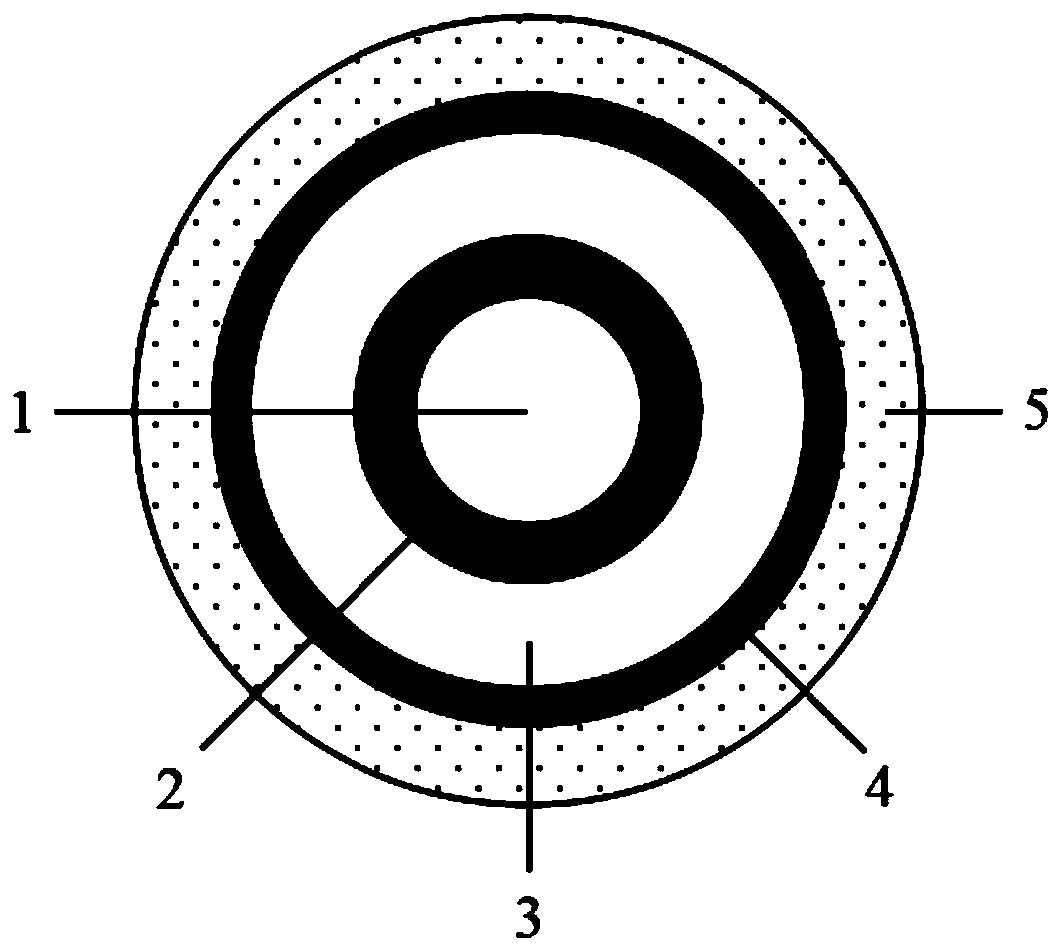

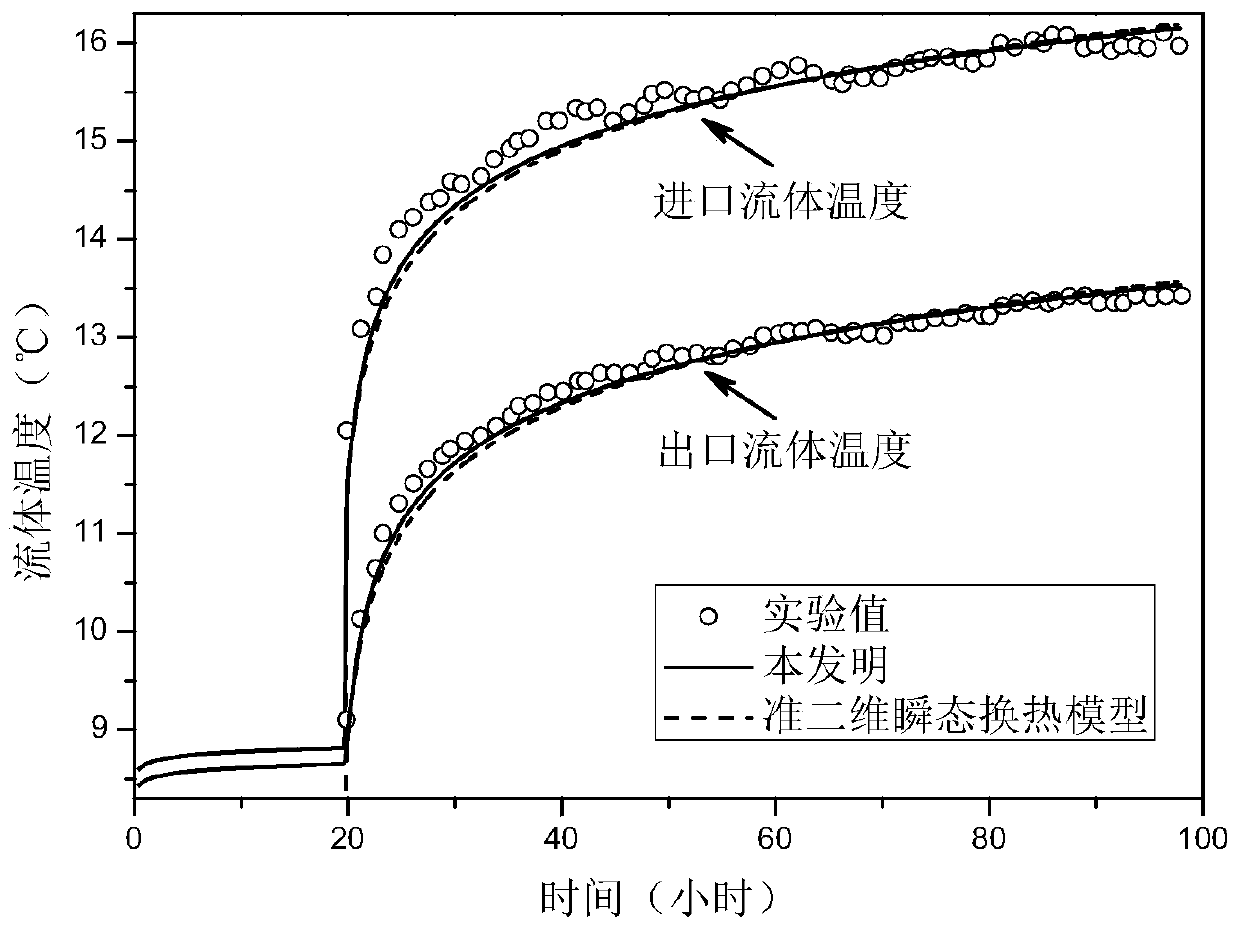

[0137] In this embodiment, the casing-type buried pipe heat exchanger is as follows: figure 1 and figure 2 As shown, the flow direction of the fluid is in and out, for the Swedish Royal Institute of Technology completed the thermal response test in 2009, calculated the fluid temperature field at different times, and compared the calculated values with the experimental values and the quasi-two-dimensional transient heat transfer model.

[0138] The total duration of the thermal response test is 97.9 hours, then the total simulation time t tol = 97.9 hours. The thermal response test includes two stages: the first 19.8 hours is the pre-circulation stage, and the heat exchange power is about 400W; the last 78.1 hours is the heat injection stage, and the heat exchange power is about 6360W. Set the time step Δt=1 minute, then the number of time segments N=t tol / Δt=5874.

[0139] Divide the inner pipe fluid 1 into 51 nodes along the axial direction, that is, M=51, and the...

Embodiment 2

[0146] In this embodiment, the casing-type buried pipe heat exchanger is as follows: figure 1 and figure 2 As shown, the flow direction of the fluid is outside in and inside out. For the deep casing type ground heat exchanger in the typical area of northern my country, the fluid temperature field at different times is calculated, and the calculated value is compared with that of Kong Yanlong et al. based on OpenGeoSys software. Compared with simulated values.

[0147] The total duration of the OpenGeoSys simulation is 120 days, then the total simulation time t tol = 120 days. Set the time step Δt=30 minutes, then the number of time segments N=t tol / Δt=5760.

[0148] Divide the inner pipe fluid 1 into 51 nodes along the axial direction, that is, M=51, and the length of the heat exchanger L=2000m, then the axial coordinate z of the mth node m =(m-1)L / (M-1)=40(m-1). Similarly, the outer tube fluid 3 is equally divided into 51 nodes along the axial direction.

[0149] At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com