Power transmission line T-shaped interface tin melting device

A technology for power transmission lines and tin melting, which is applied to line/collector parts, circuits, connections, etc., can solve the problems of affecting the conductivity of power lines, easy to oxidize, easy to break, etc., achieve fast cooling, avoid tin liquid overflow, The effect of reducing the oxidized area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

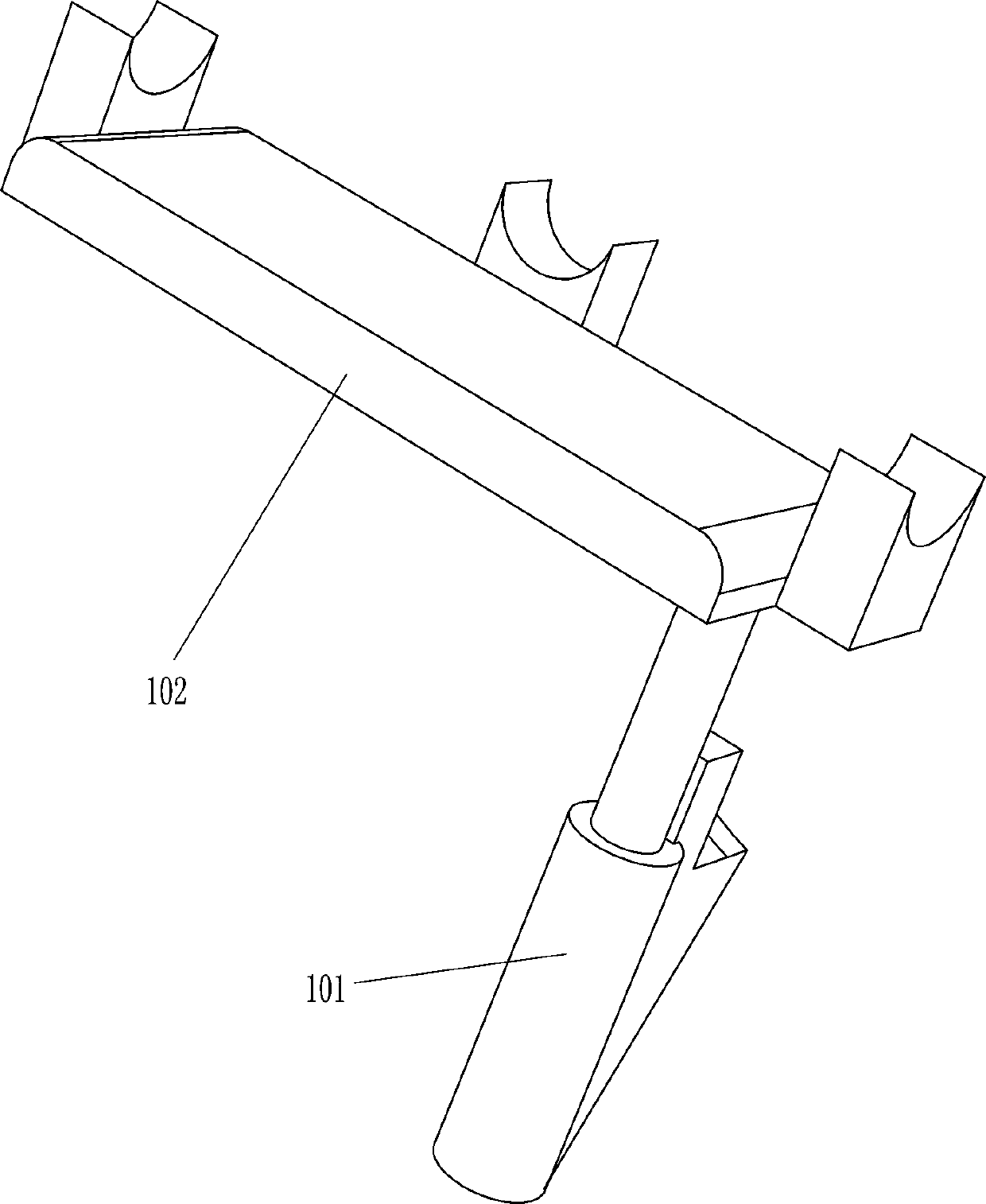

[0029] A tin melter with a T-shaped interface for transmission lines, see figure 1 , figure 2 and Figure 4 , including support 1, tin melting furnace 3, handle 8, discharge mechanism 9 and fixing mechanism 10, tin melting furnace 3 is installed on the right side of support 1, a cover is provided on the right side of the top of tin melting furnace 3, tin melting furnace 3 The right front side is connected with a handle 8, and the tin melting furnace 3 is equipped with a discharging mechanism 9 and a fixing mechanism 10.

[0030] It also includes a control module, a discharge key 4, a material return key 5, a clamping key 6 and a release key 7. The front side of the tin melting furnace 3 is sequentially provided with a discharge key 4, a material return key 5 and a clamping key from top to bottom. The tightening key 6 and the handle 8 are provided with a release key 7, and the discharge key 4, the return key 5, the clamping key 6 and the release key 7 are all electrically co...

Embodiment 2

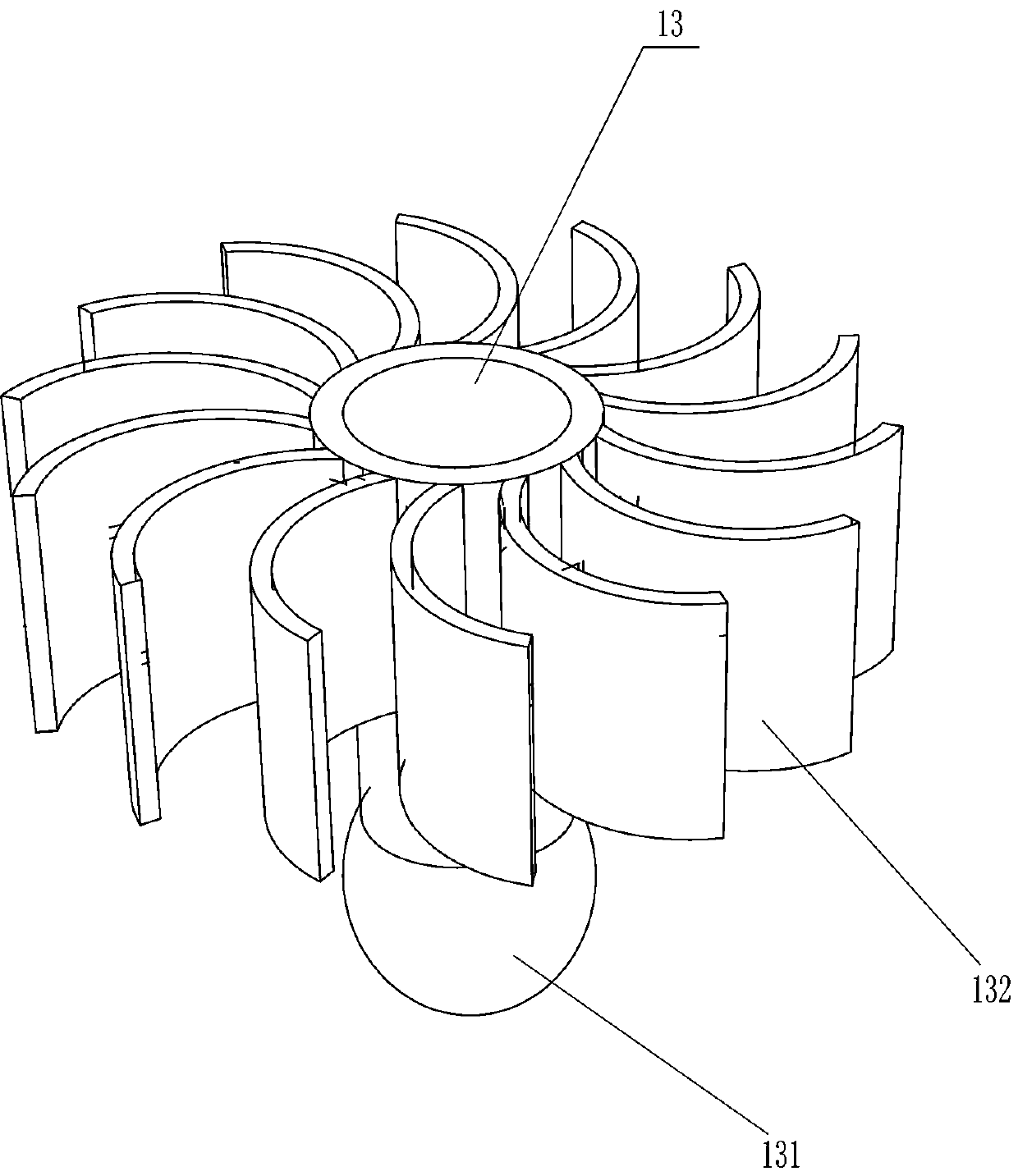

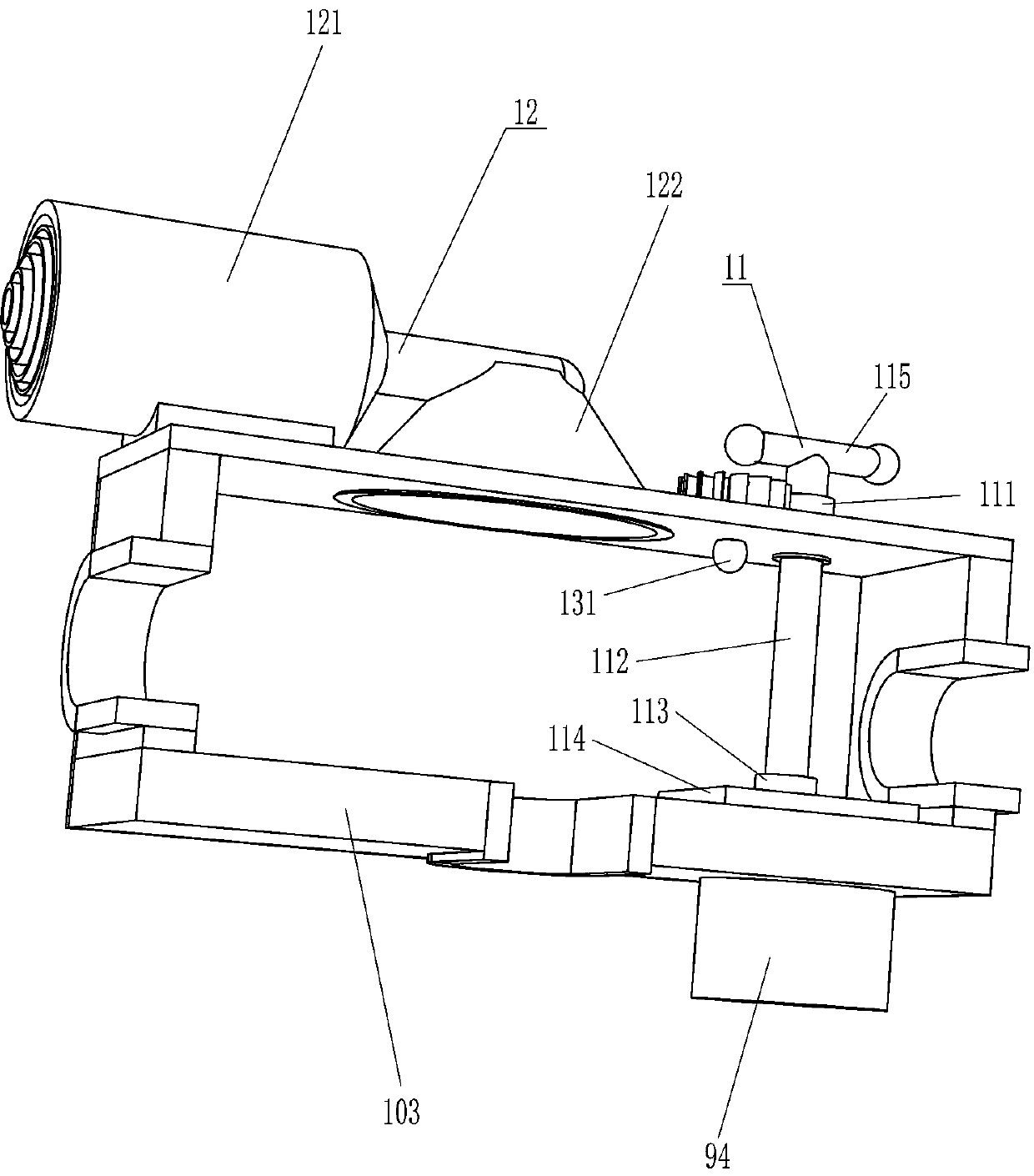

[0037] On the basis of Example 1, see image 3 and Figure 5 , also includes sealing mechanism 11, and sealing mechanism 11 comprises nut 111, screw rod 112, axle sleeve 113, baffle plate 114 and rotating rod 115, and the right side of receiving box 103 top is embedded with nut 111, and screw rod is arranged in nut 111 112, the bottom of the screw rod 112 is connected with an axle sleeve 113 through interference, the bottom of the axle sleeve 113 is connected with a baffle plate 114, the baffle plate 114 is in contact with the inner bottom of the storage box 103, and the top of the screw rod 112 is connected with a rotating rod 115.

[0038] Also include a cooling mechanism 12, the cooling mechanism 12 includes an air pump 121 and an air outlet cover 122, the left side of the storage box 103 top is equipped with an air pump 121 by bolts, the right side of the air pump 121 is connected with an air outlet cover 122, and the shape of the air outlet cover 122 is a trumpet , the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com