A kind of solvent-resistant and seawater-resistant high-expansion foam fire extinguishing agent and its preparation and use method

A foam fire extinguishing agent, high-multiplier technology, applied in the field of foam fire extinguishing agent, can solve the problems of poor anti-solvent effect, complex components, short storage period, etc., to facilitate large-scale industrial production, simple preparation process, and low manufacturing cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

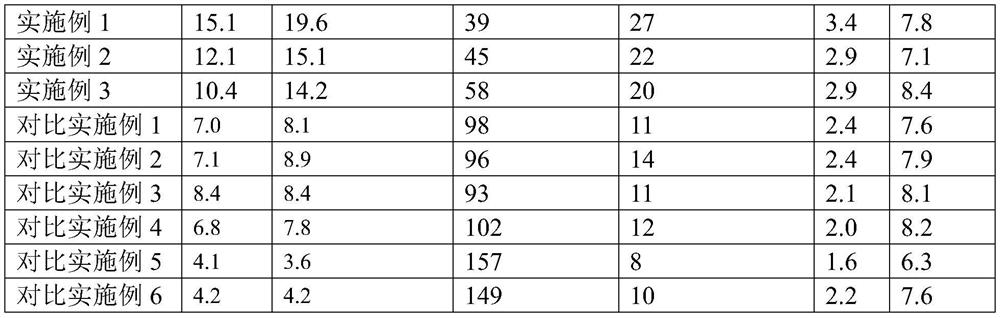

Embodiment 1

[0046] Heat the mixing reactor to 75 to 90°C, add 18kg of water, 65kg of cocamidopropyl betaine surfactant, 18kg of sodium methyl lauroyl taurate, stir for 30min, and then add 18kg of succinate in sequence Sodium diisooctyl sulfonate; 8kg of a mixture of ethylene glycol and ethylene glycol butyl ether (the volume ratio of ethylene glycol and ethylene glycol butyl ether is 3:7); 4kg of alkyl glycosides, 15kg of dodecane base ether, and continued to stir for 30 min to obtain Component A.

[0047] Mix 0.6-0.7% non-ionic polyacrylamide solution with 0.4-0.5% carboxymethyl cellulose solution to obtain component B.

[0048] The volume ratio of component A and component B is 7:3, and component A and component B will be stored separately.

Embodiment 2

[0050] Component A and component B were prepared in the same manner as in Example 1, except that the volume ratio of component A and component B was 9:2.

Embodiment 3

[0052] Component A and component B were prepared according to the same method as in Example 1, except that the volume ratio of component A and component B was 6:3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com