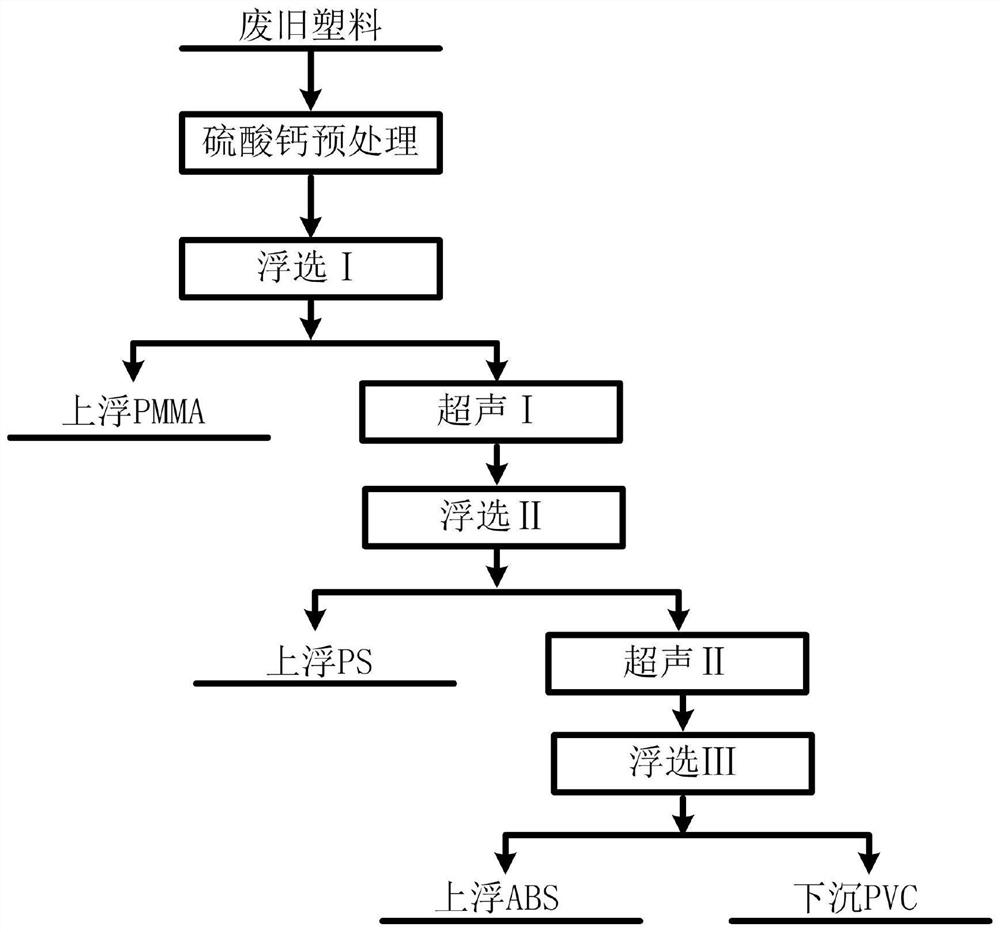

A full-priority flotation separation method for waste mixed plastics based on calcium sulfate pretreatment

A technology of mixing plastics and preferential flotation, applied in the field of waste plastic recycling, can solve the problems of changing the chemical structure of the plastic surface, high energy consumption, poor test reproducibility, etc., to achieve high selective separation, high recovery rate, and guaranteed process effects The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Mixed plastic containing PMMA, PVC, PS, and ABS was cleaned, crushed, 5g of 3 to 5 mm particle diameter (PMMA: PVC: PS: ABS mass ratio 1: 1: 1), at 60 Under the conditions of ° C, contain 0.1 g / lcaso 4 The aqueous solution was stirred in 100 mL, the stirring time was 15 to 30 min, and the rotation speed was 800 to 1200 r / min, and the plastic particles were flotted. The suitable flotation conditions were pine oil alcohol 200mg / L, pneumant 700 ~ 800ml / min, the flotation time is 3 min, and the purity of PMMA was separated by flotation I was 97.1%, and the recovery rate was 97.3%. Ultrasound treatment (PVC, PS and ABS) is then subjected to ultrasonic treatment (PVC, PS and ABS), and then the second flotation is carried out to obtain 92.3% purity of the upper float PS purity, the recovery rate of 94.6%, and the sink mixed product ABS and PVC. Ultrasound treatment (power 100w, ultrasonic time 30min) was performed, and the treated plastic mixture was subtrained to give ABS...

Embodiment 2

[0051] Mixed plastic containing PVC, PS, ABS was cleaned, broken, and a plastic particles of 3 to 5 mm particle diameter (PVC: PS: ABS were 1: 1: 1: 1: 1: 1: 1: 1: 1: 1: 100ml under conditions of 45 ° C) Caso concentration is 0.2g / L 4 The aqueous solution is pretreated, the stirring time is approximately 10 min, the rotation speed is 200 ~ 300R / min, filtration, and the flotation separation is performed. The suitable flotation conditions are pine alcohol 200mg / L, the gas amount of 700 ~ 800 mL / min, floating In the selection time, 3 min was selected, and the PS purity of the upper floating product was 95.6%, the recovery rate was 96.8%, and then the lower backwrapping product (PVC and ABS) was easily treated (power 600W, ultrasonic time 10min), and then the second floating The concentration of ABS was 94.2%, 97.1% of the recovery rate, 97.5% pVC, and the recovery rate was 94.6%.

Embodiment 3

[0053] The mixed plastic containing PVC, ABS, and PMMA was cleaned, broken, 3 to 5 mm of plastic particles 2g (PMMA: PVC: ABS), 1: 1: 1: 1: 1: 1: 1: 1: 1: 1: Under the conditions of 40 ° C, 100ml concentration of Caso at 0.09g / L 4 The aqueous solution was treated for 10 min, and the stirring speed during treatment was 800r / min, filtered, and the flotation separation was performed. The suitable flotation conditions were pneumonol alcohol 200mg / L, the amount of air volume of 700 ~ 800 ml / min, flotation time 3 min, After the first flotation, the upper floating product PMMA was 96.4%, and the recovery rate was 94.7%. The sink mixture (PVC and ABS) passes through the ultrasonic treatment (power 150W, ultrasonic time of 25 min), then performing a second flotation to obtain a purity of the upper floating ABS purity purity purity of 91.6%, recovery rate of 92.8%, low sink product PVC purity 91.2%, recovery 99.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com