Desulfurization wastewater concentrated solution atomization device and atomization anti-blocking method

A technology for desulfurization wastewater and atomization device, which is applied in chemical instruments and methods, general water supply conservation, gaseous discharge wastewater treatment, etc. The effect of reducing amplitude stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

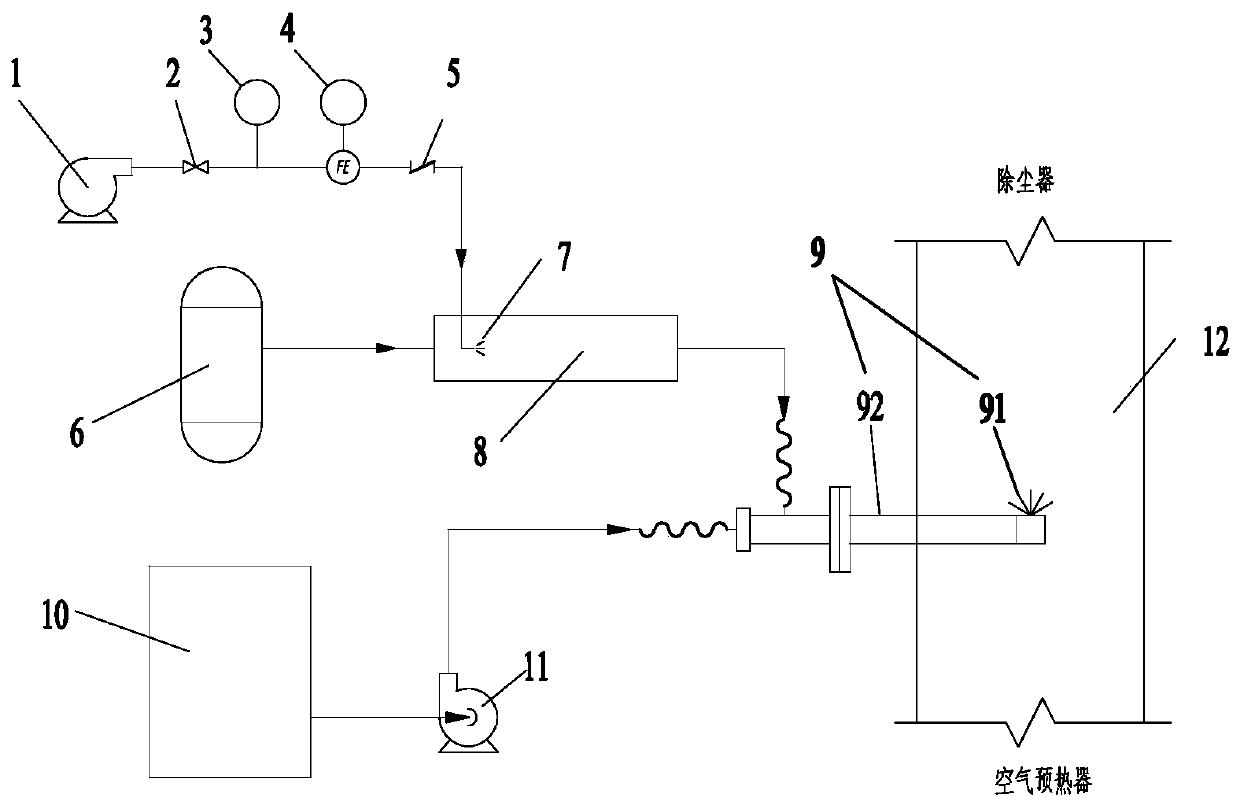

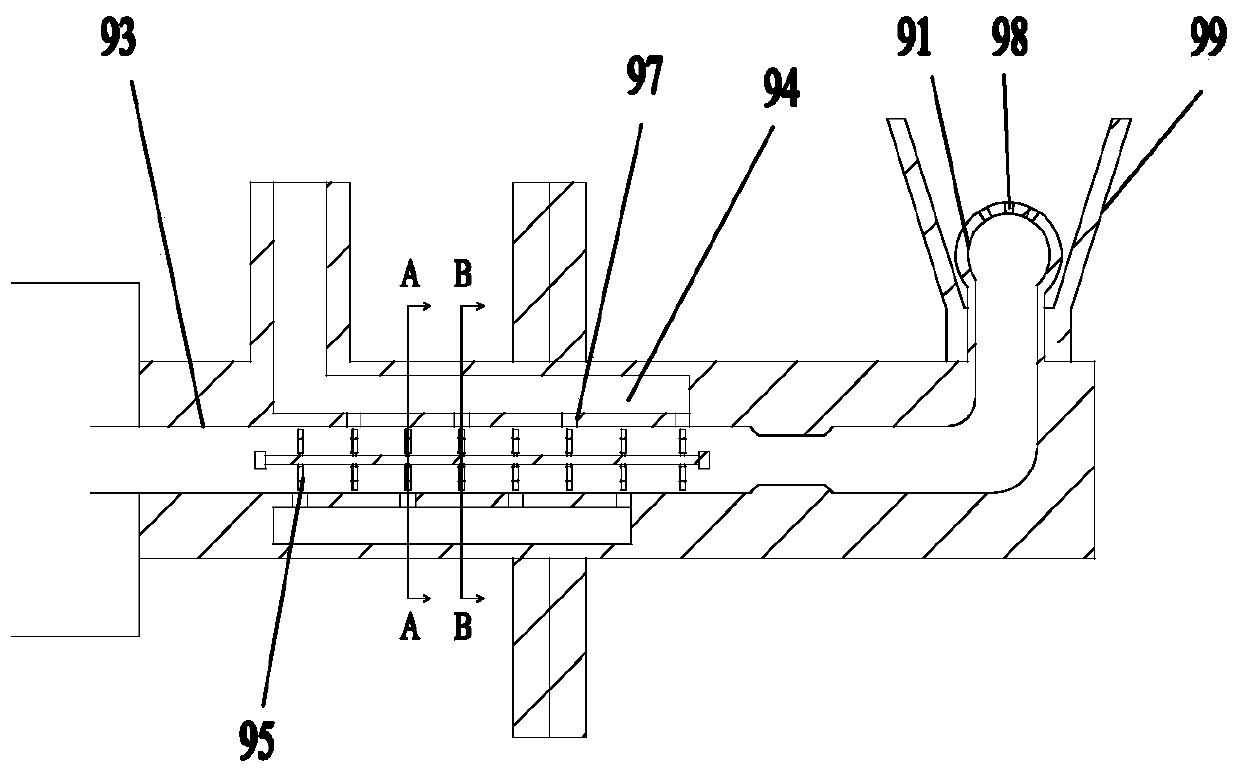

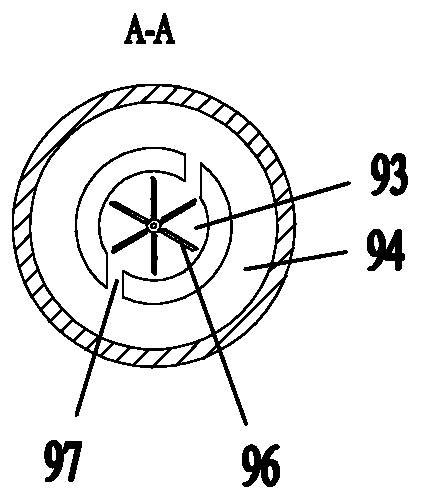

[0025] Such as Figure 1-4 In the shown embodiment, a desulfurization wastewater concentrate atomization anti-blocking device includes a dual-fluid spray gun 9, the nozzle of the dual-fluid spray gun is located in the evaporation flue 12, and the two inlets of the dual-fluid spray gun are respectively Connect the jet pump 11 and the air-water mixer 8, the jet pump is connected with the desulfurization wastewater concentrated liquid storage tank 10, the air-water mixer is connected with the compressed air storage tank 6 and the humidification water pump 1, the humidification water pump and the gas A regulating valve 2, a pressure gauge 3, a flow meter 4, a check valve 5, and a fine atomizing nozzle 7 are sequentially connected between the water mixers, and the fine atomizing nozzle is located in the air-water mixer; the two-fluid spray gun inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com