A rolling glass melting furnace and its strengthening method

A glass melting furnace and calendering technology, applied in glass calendering, glass molding, glass furnace equipment, etc., can solve problems such as high-temperature gas escaping, collapse, and burning supporting steel components, and achieve the effect of height reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

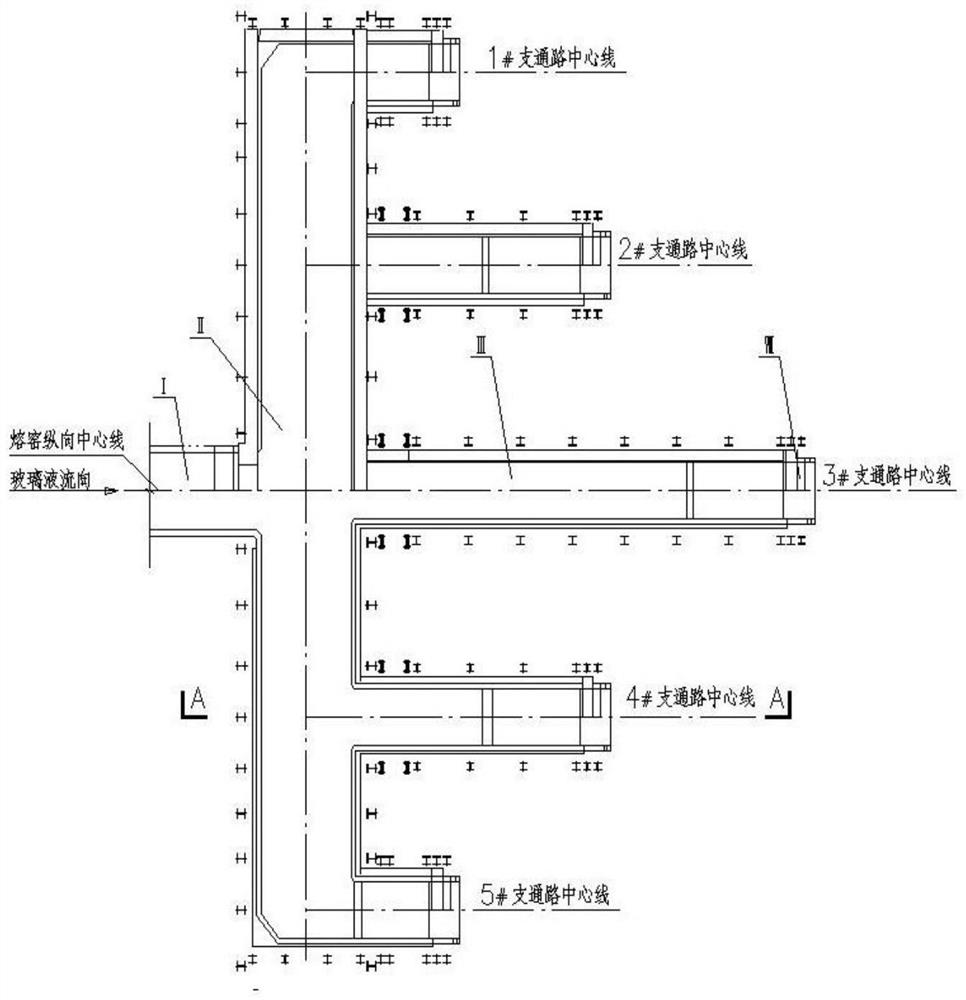

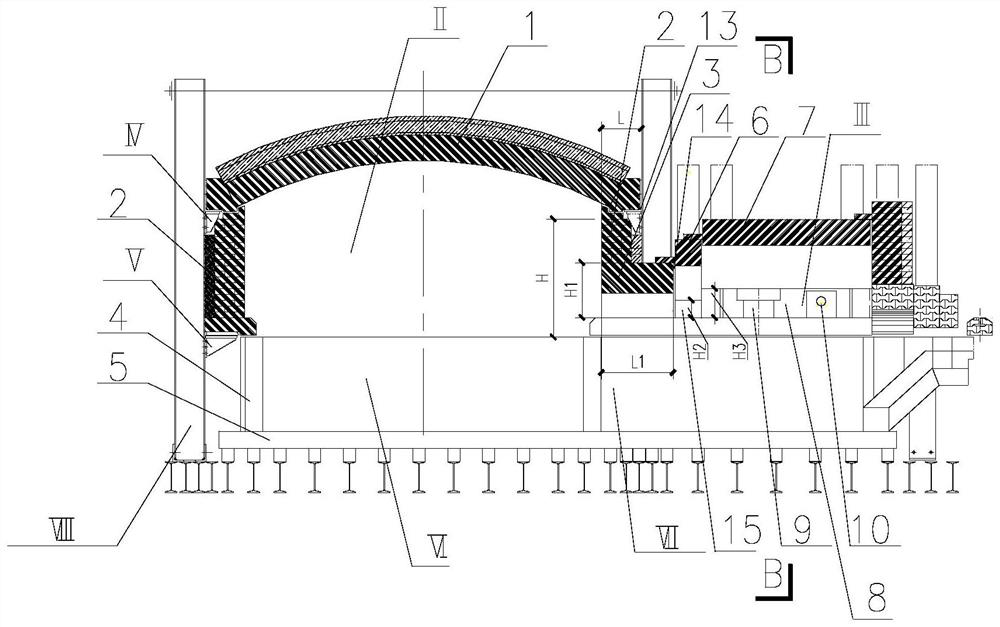

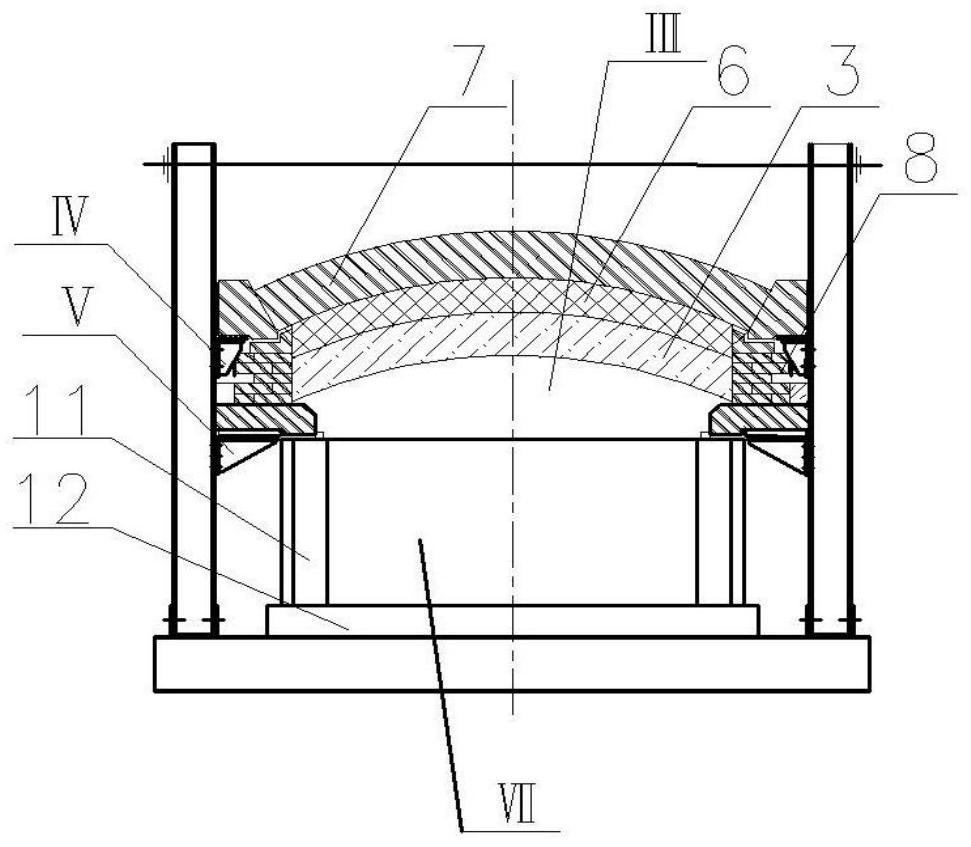

[0024] In order to prolong the service life of the glass melting kiln for the photovoltaic glass of the calendering process, the present invention adds a transition wall between the branch channel entrance wall and the branch channel wall as a reinforcement device, and the height of the transition wall (the height of the wall all refers to the The distance from the top to the top surface of the glass pool wall) is 235mm-610mm lower than the height of the branch passage, and 150mm-240mm higher than the height of the branch passage entrance. The entrance of the branch passage is built on the top surface of the glass liquid pool of the horizontal passage, which is equivalent to the height of the breast wall is 0, and the height between the entrance and the top of the bridge is 610mm-630mm from the top of the pool wall; the transitional bridge is built on the transitional breast wall , parapet height H 2 180mm-200mm, the height between the transitional crown and the parapet top is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com