Composite protective film

A technology of protective film and protective layer, which is applied in the direction of film/sheet adhesive, gaseous chemical plating, polyurea/polyurethane coating, etc. Damaged by sharp objects, etc., to achieve the effect of improving resistance to external environment, long-term appearance, beautiful and clean, and good anti-ultraviolet performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

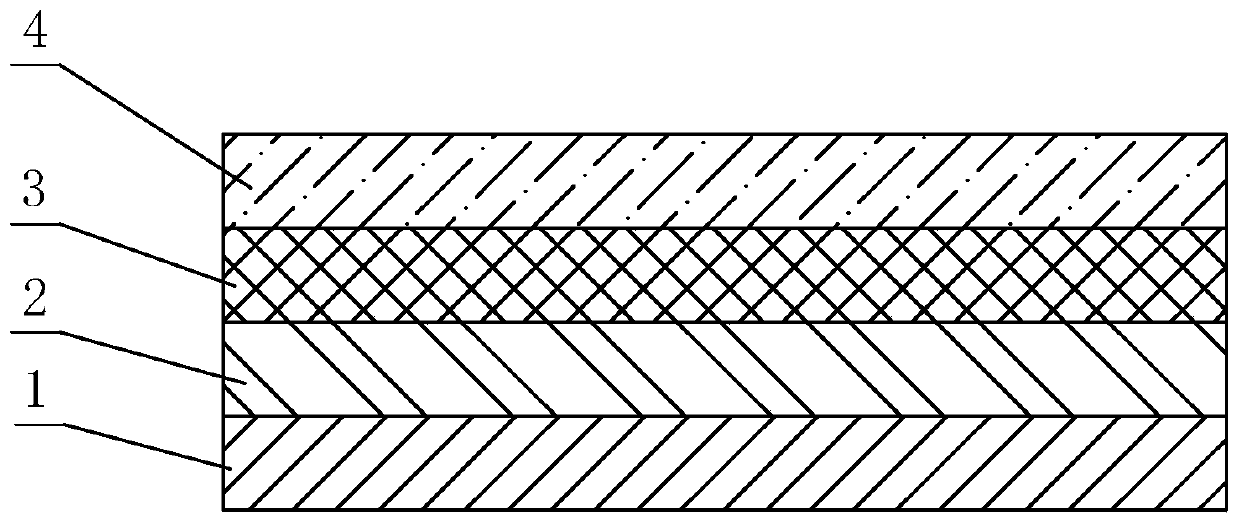

[0076] see figure 1 , the composite protective film, which is composed of a release layer 1, an adhesive layer 2, a weather-resistant protective layer 3, and a hydrophobic layer 4, and each layer is composited into one; the release layer 1 is the bottom layer, and its surface is attached to the adhesive layer 2, the bottom surface, the bottom surface of the weather-resistant protective layer 3 is attached to the surface of the adhesive layer 2, and the hydrophobic layer 4 is the surface layer, and is attached to the surface of the weather-resistant protective layer 3.

[0077] The weather-resistant protective layer 3 is provided with at least one layer, the bottom surface of the weather-resistant protective layer 3 of at least one layer is attached to the surface of the adhesive layer 2, and the surface of the weather-resistant protective layer 3 of at least one layer is attached to the bottom surface of the hydrophobic layer 4.

[0078] The weather-resistant protective layer ...

no. 2 example

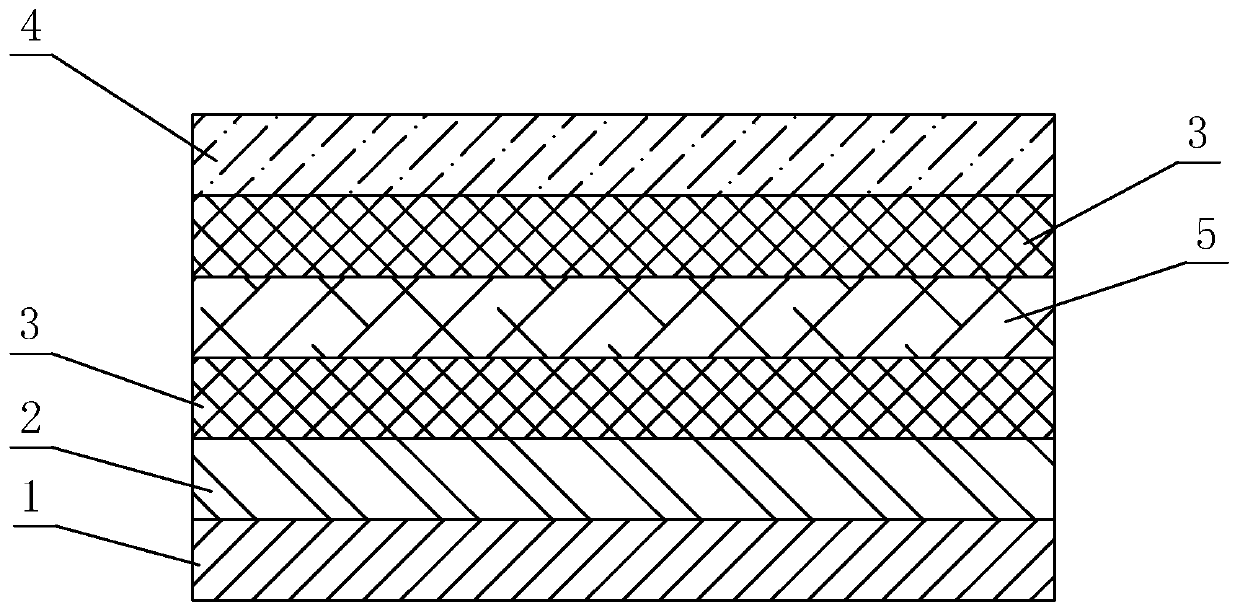

[0149] see figure 2 , the composite protective film, which is different from the first embodiment in that: the weather-resistant protective layer 3 is provided with several layers, an adhesive layer 5 is arranged between several layers of weather-resistant protective layers 3, and the adhesive layer 5 passes through each other Mutual attachment; wherein, the bottom surface of the weather-resistant protective layer 3 at the bottom is attached to the surface of the adhesive layer 2, and the surface of the weather-resistant protective layer 3 at the top is attached to the bottom surface of the hydrophobic layer 4.

[0150] The weather-resistant protective layer 3 in this embodiment is provided with two layers, and the two weather-resistant protective layers 3 are attached to each other through the adhesive layer 5 . The bottom surface of the weather-resistant protective layer 3 located in the lower layer is attached to the surface of the adhesive layer 2 , and the surface of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com