Differential pressure valve assembly

A valve chamber, valve seat technology, applied in valve devices, valve operation/release devices, valve lifters, etc., to solve problems such as reduced efficiency, unpredictability, and limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

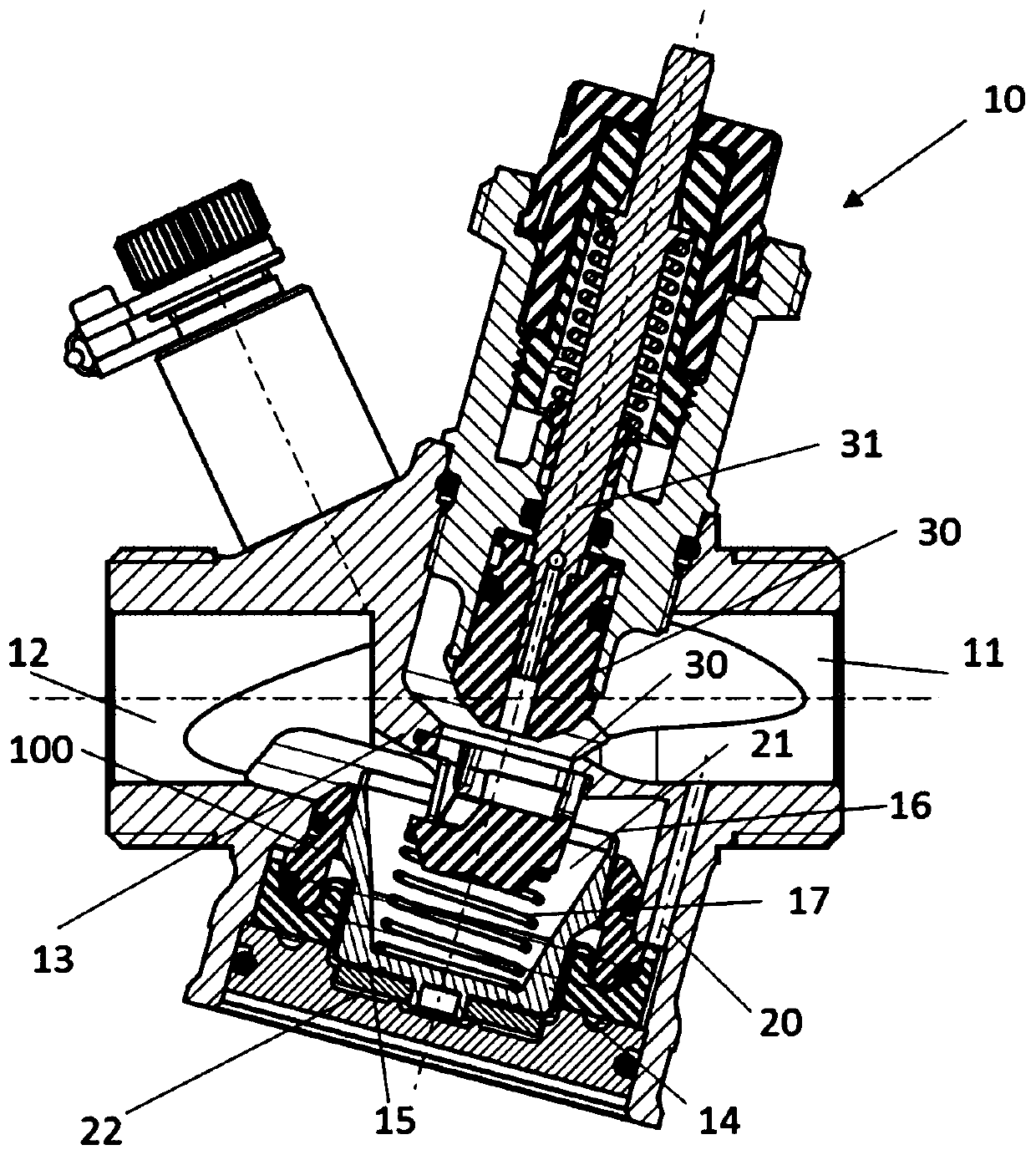

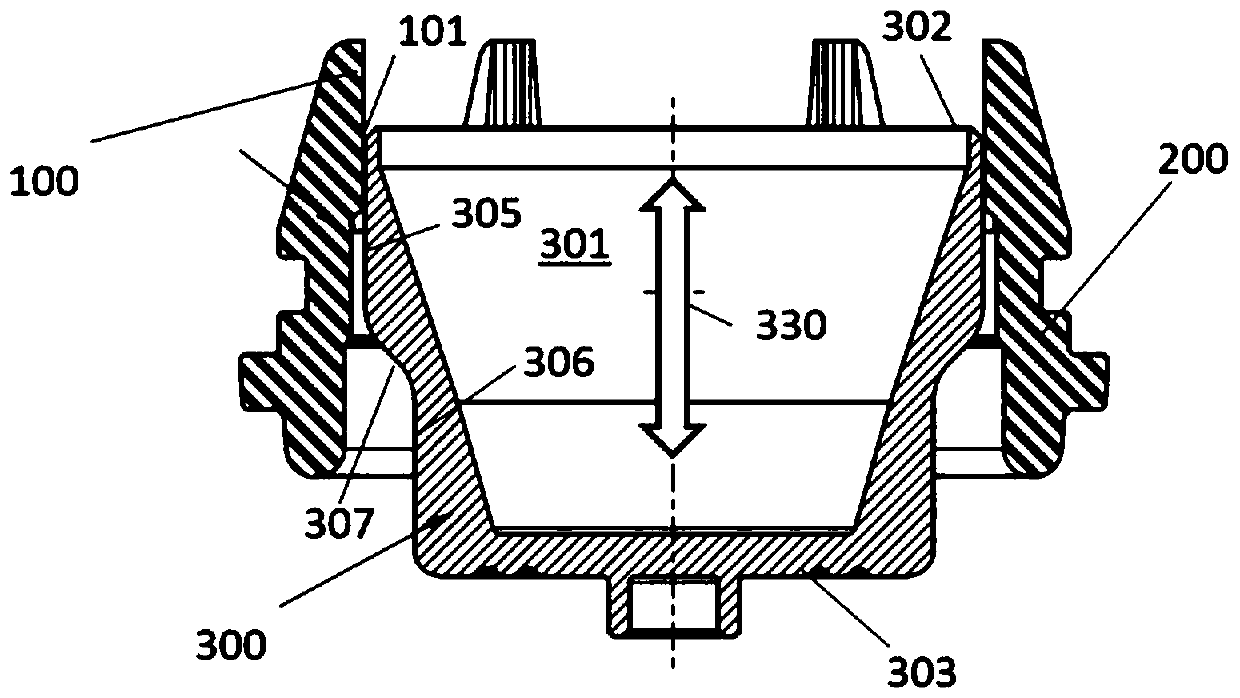

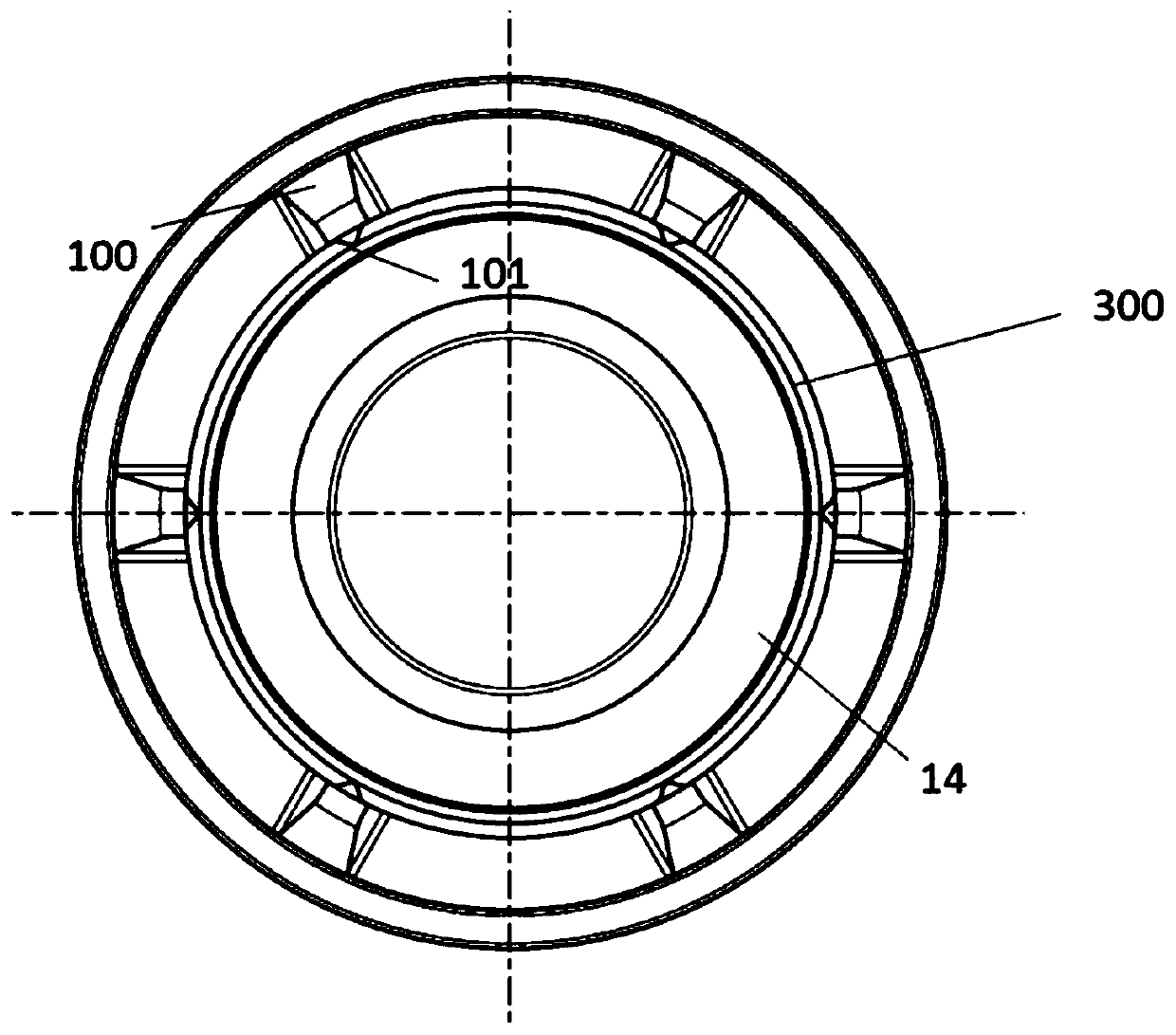

[0023] figure 1 A pressure control valve 10 is schematically shown comprising a gate 14 or valve element arranged in a valve chamber 16 positioned between at least one fluid inlet 11 and at least one fluid outlet 12 . The gate 14 is adapted to move relative to the valve seat 13 which defines a first degree of opening of the pressure control valve 10 based on the distance between the two parts. Fluid thus passes from the inlet 11 through the pressure control valve 10 to the outlet 12 with a flow rate regulated in the usual manner through the valve opening formed between the valve seat 13 and the gate 14 .

[0024] In the figure, an optional further flow control valve is located between said inlet 11 and outlet 12 formed by a flow control valve element 30 cooperating with a second valve seat 32 and connected at the valve At the first end of the pin 31, the second end of the valve pin is optionally connected to an actuator.

[0025] The gate 14 is fixed to a diaphragm 15 which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com