Concrete crack control device and control system thereof

A control device and concrete technology, applied in the field of concrete, can solve the problems of low operability, inability to achieve precision, and small constraint range of steel hoop, and achieve the effects of strong operability, ensuring comparability, and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

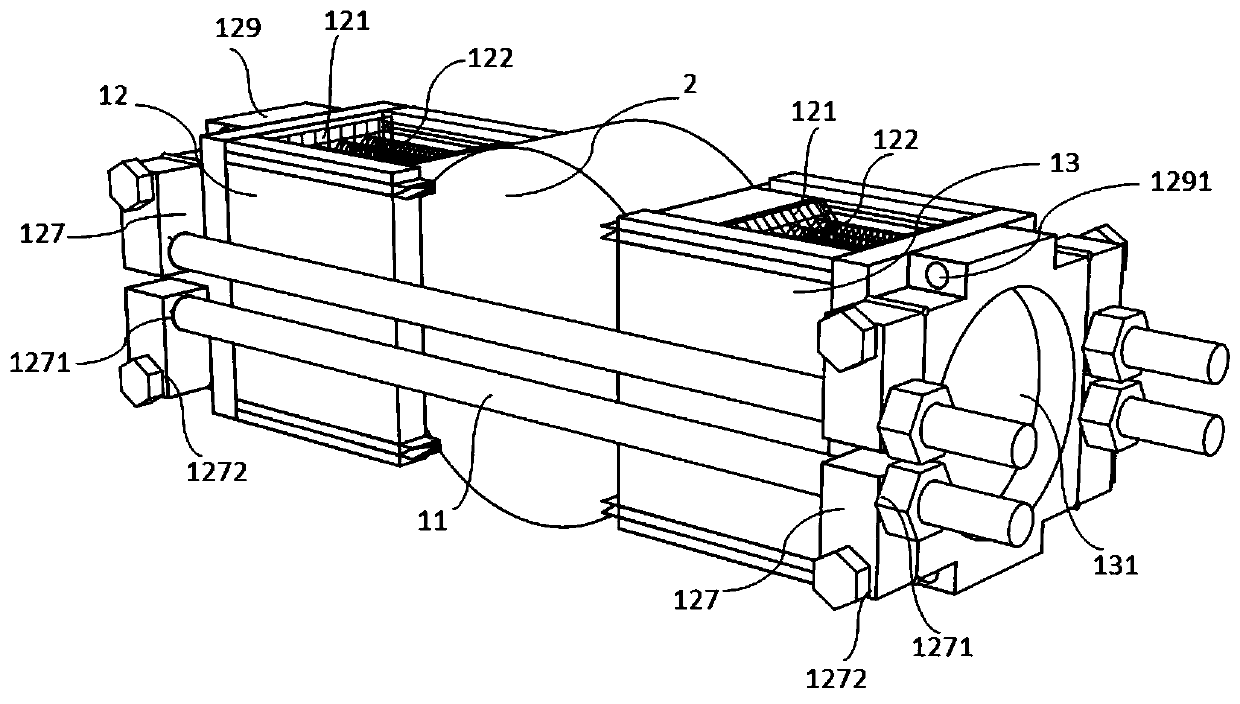

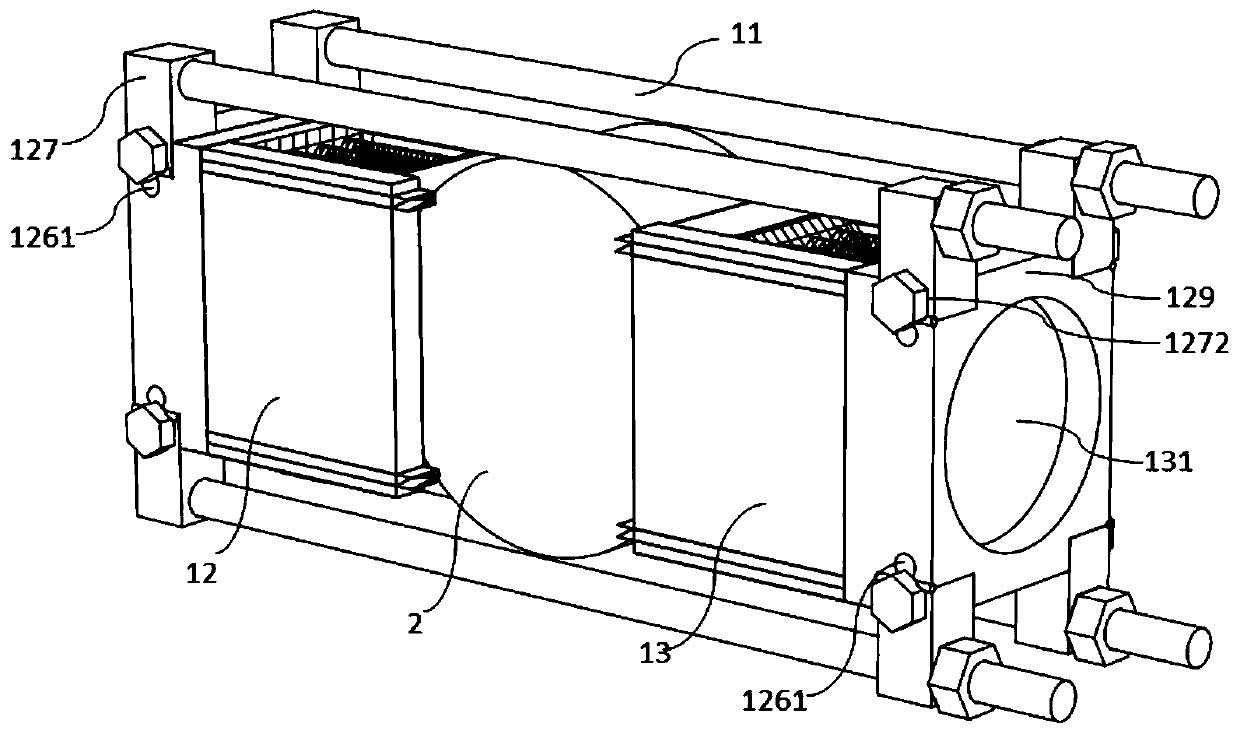

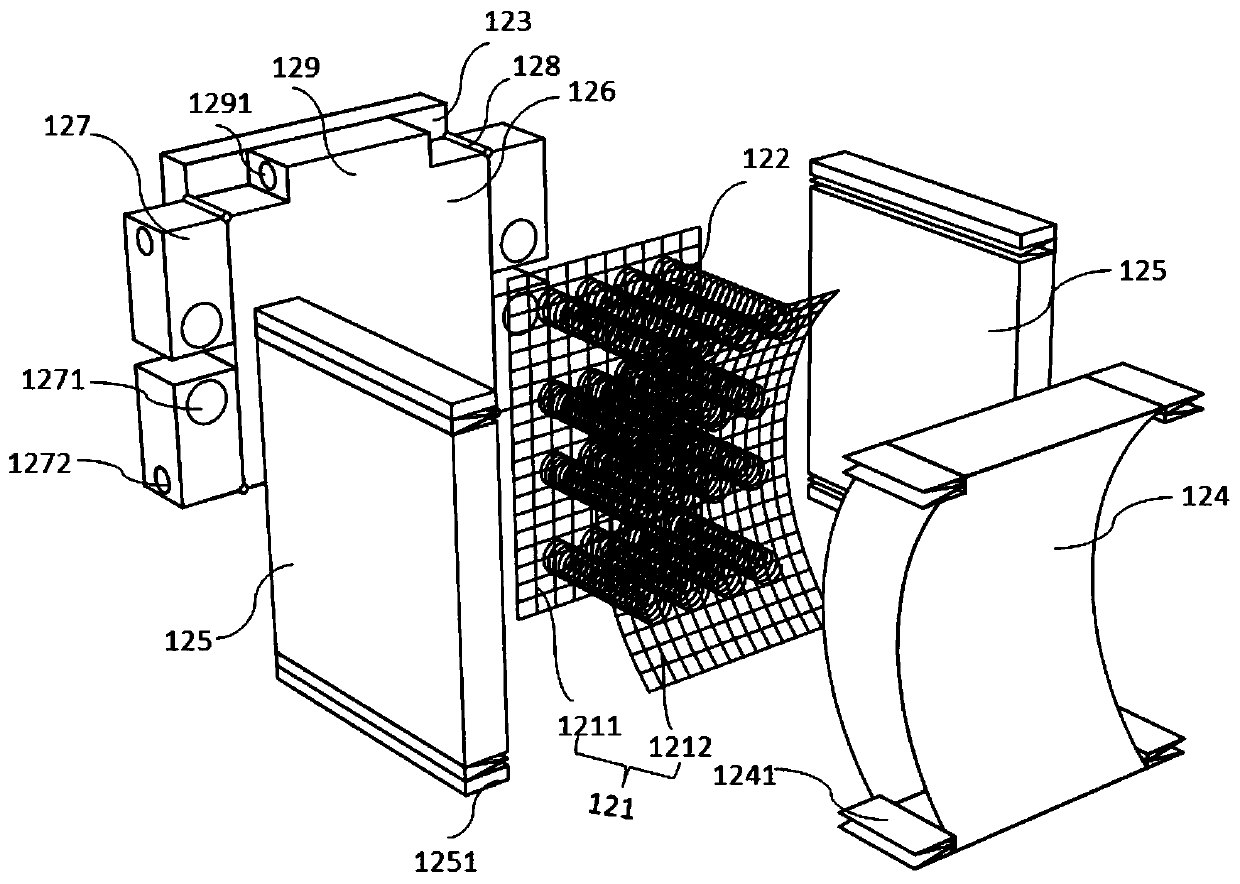

[0031] In order to solve the above problems, a concrete crack control device is provided in Embodiment 1 of the present invention, such as Figure 1 ~ Figure 3 As shown, the concrete crack control device 1 includes: a long screw 11; connected by the long screw 11, it is used to clamp the concrete sample 2 and apply a preload to the concrete sample 2. The clamping assembly 12 and the second clamping assembly 13; the first clamping assembly 12 and the second clamping assembly 13 both include a balance steel net 121 and a spring module wound and fixed on the balance steel net 121 122. When it is necessary to artificially create cracks on concrete sample 2, such as figure 1 As shown, the concrete sample 2 is placed between the first clamping assembly 12 and the second clamping assembly 13, and the long screw 11 is fixed by a hexagonal nut, and then the concrete sample 2 is subjected to pressure to create a crack. The width of the surface crack of the concrete sample 2 can be adj...

Embodiment 2

[0040] Embodiment 2 of the present invention provides a concrete crack control system, such as Figure 4 and Figure 5 As shown, the system includes a pressure testing machine 3 and the above-mentioned concrete crack control device 1, the pressure testing machine 3 is provided with a base 31 for fixing the concrete crack control device, and the base 31 is arranged on the The pressure testing machine 3 is directly below the upper indenter. After the concrete sample 2 is fixed on the concrete crack control device 1, the concrete crack control device 1 is fixed on the base 31. At this time, the concrete sample 2 is located directly below the upper pressure head of the pressure testing machine 3, and the upper pressure The head starts to squeeze the concrete sample 2 downwards at a set constant rate, and observes whether microscopic cracks appear on the concrete sample 2 through a portable optical microscope during this period. Once a microscopic crack occurs, the pressure testin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com