Core layer of perovskite nanowire with tiled shell-core structure and solar cell manufacturing method of core layer

The invention relates to a technology for a solar cell and a manufacturing method, which is applied in the field of solar cells, and can solve the problems affecting the performance of the device, and achieve the effects of reducing the electron-hole recombination rate, reducing the volume, and increasing the diffusion strength and service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

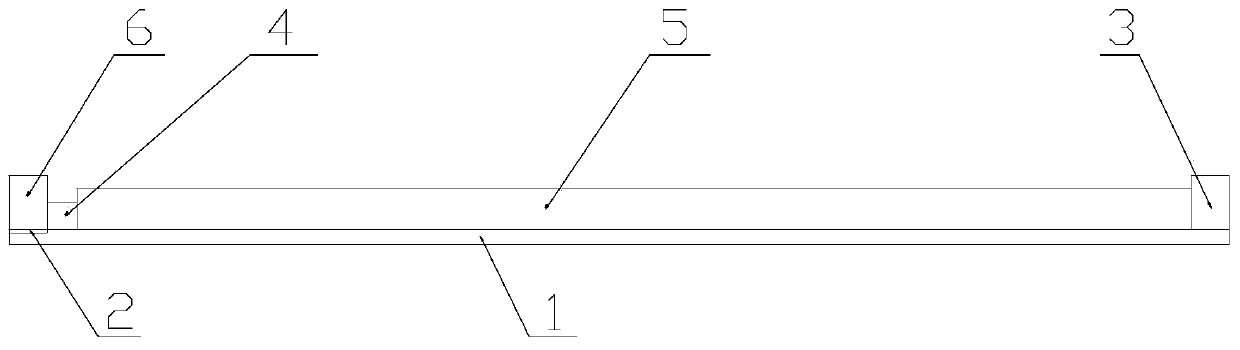

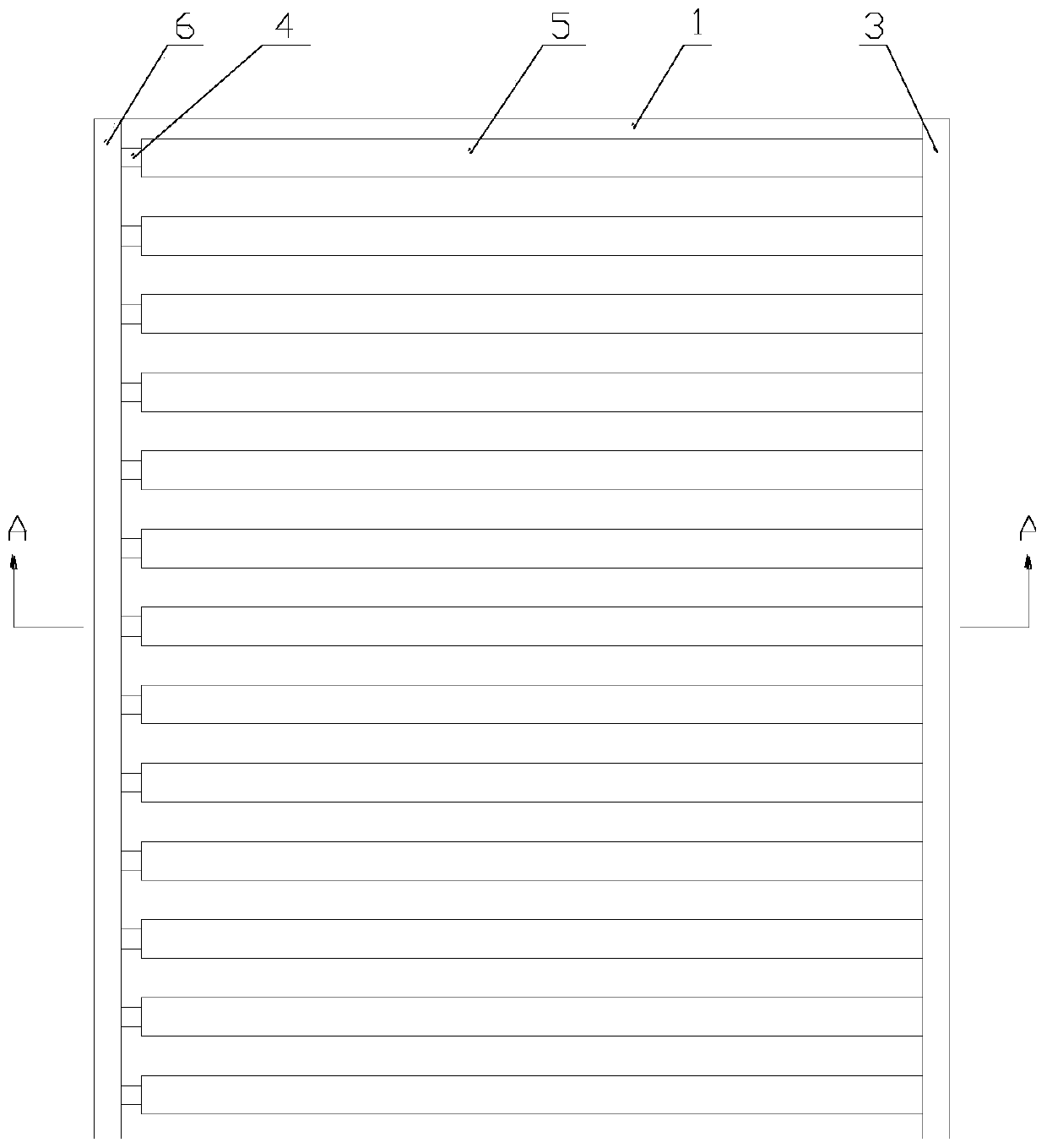

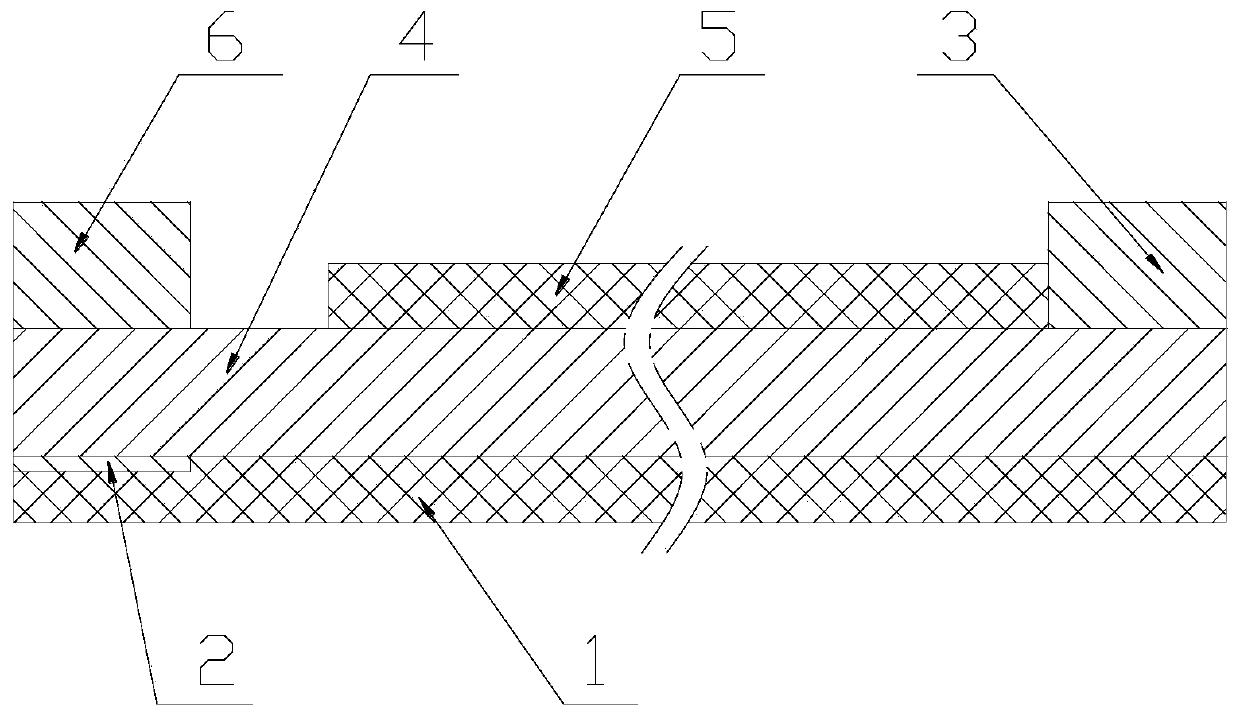

[0032] See Figure 1-Figure 3 , Is a flat shell-core structure perovskite nanowire solar cell, including a sheet-shaped substrate (using an insulating material), and both ends of the substrate are respectively electroplated with strip-shaped first electrodes and first electrodes Two electrodes, the first electrode and the second electrode are parallel to each other, a plurality of shell-core structure perovskite nanowires are arranged along a plane array between the first electrode and the second electrode, and each shell-core structure perovskite nanowire Parallel to each other, the shell-core structure perovskite nanowire includes a core layer made of a transmission material and a shell layer made of a perovskite material. The core layer is connected to the first electrode, and the shell layer is connected to the second electrode. connection.

[0033] The core layer is arranged on the substrate, one end of the core layer is connected to the first electrode, and the shell layer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com