Parapet wall cornice lightning protection belt support construction method

A parapet and lightning protection belt technology, applied in roofing, electrical components, buildings, etc., can solve problems such as poor economic benefits, waste of labor, and slow construction speed, and achieve the effects of simple construction, flexible operation, and improved construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

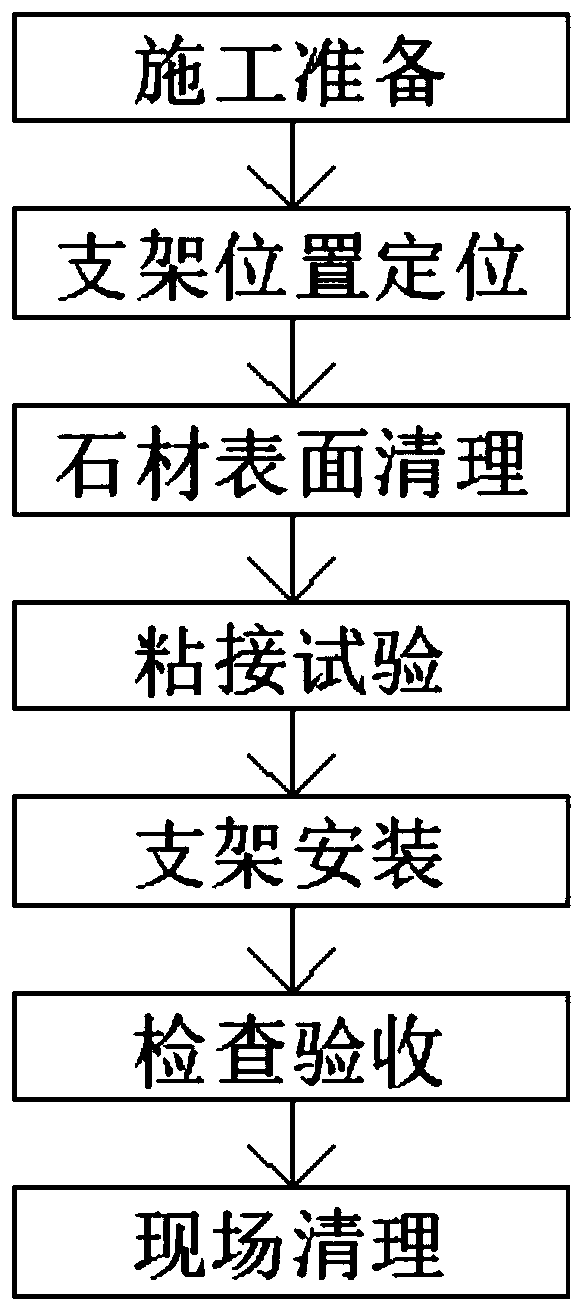

Image

Examples

Embodiment 1

[0036] The China Railway Construction Plaza project in Lot 1-10 of Laiguangying, Chaoyang District is a landmark construction project in Laiguangying area. It is located in Qingheying Village, Laiguangying Township, Chaoyang District, Beijing. China Railway Construction Group Co., Ltd. undertakes construction of B, Buildings C and D have three commercial office buildings and underground garages, with a construction area of about 110,688m2, an underground area of 34,355m2, and an aboveground area of 76,332m2. The project start date is November 20, 2012, and the completion date is December 30, 2014. The structure is Frame-shear wall, 3 / 4 floors underground, 27 / 29 floors above ground, the exterior walls of the three buildings are all designed with slotted dry-hanging stone, and the structural cavity is 400mm. Nearly 350 lightning protection belt brackets on the top of the parapet, with a diameter of 100mm and an installation height of 110mm, used a total of nearly a small bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com