Flexible permanent magnet brushless direct current motor control system and control method thereof

A permanent magnet brushless DC and motor control technology, applied in the control system, electronic commutation motor control, single motor speed/torque control, etc., can solve the problem of different current change rates, affecting system reliability, uneven current distribution, etc. Problems, to achieve the effect of large electromagnetic torque, widen the speed range, improve power density and load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are enumerated hereby, and detailed descriptions are as follows in conjunction with the accompanying drawings:

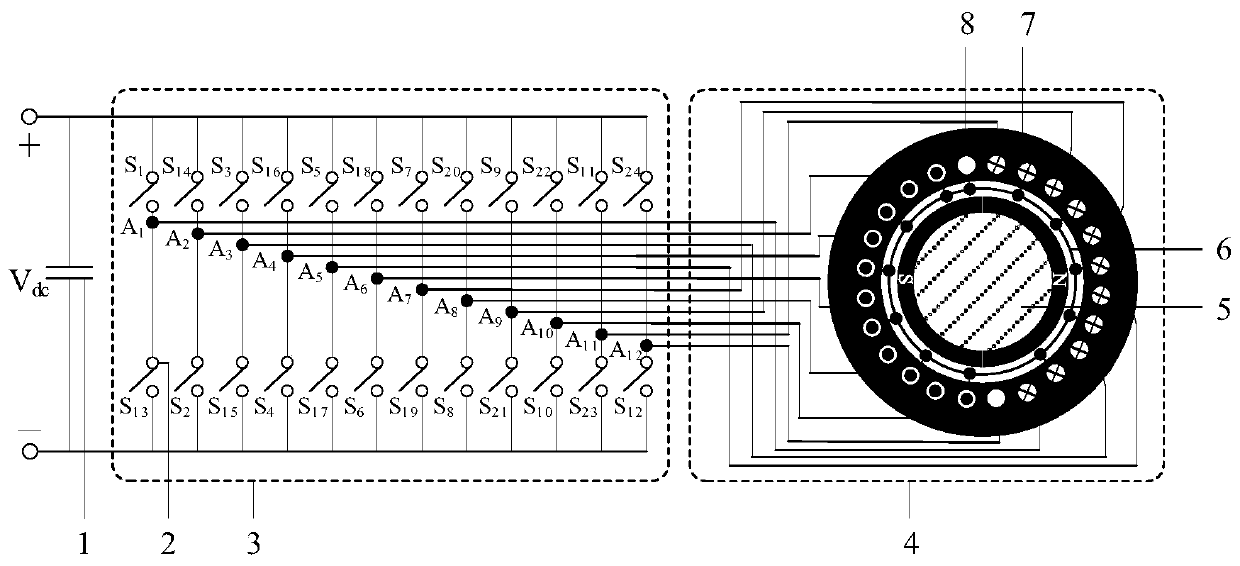

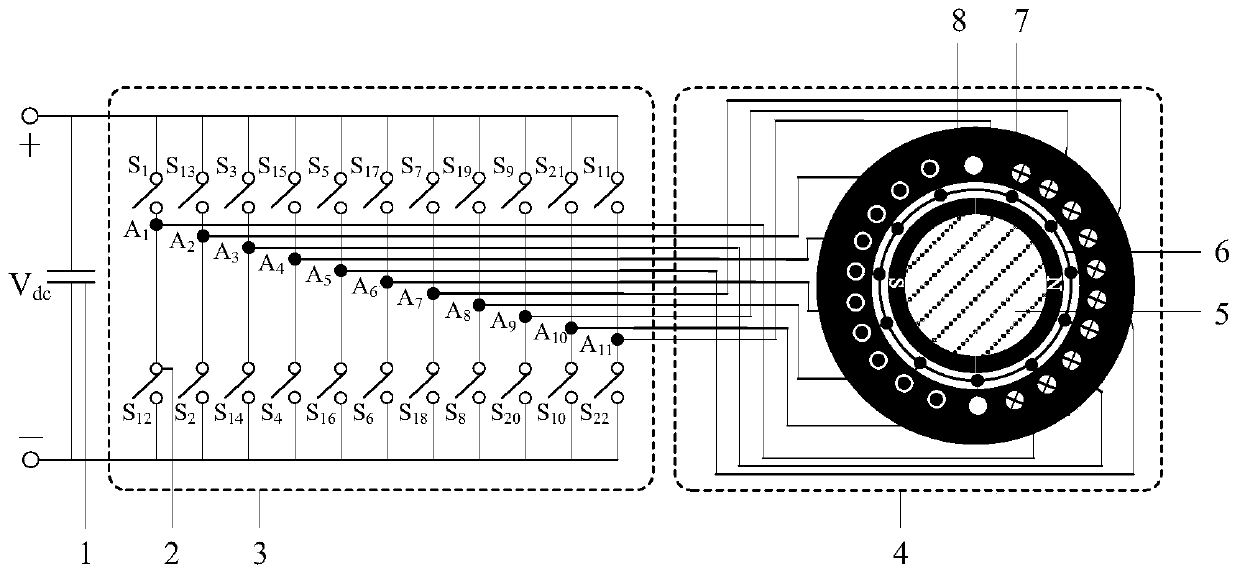

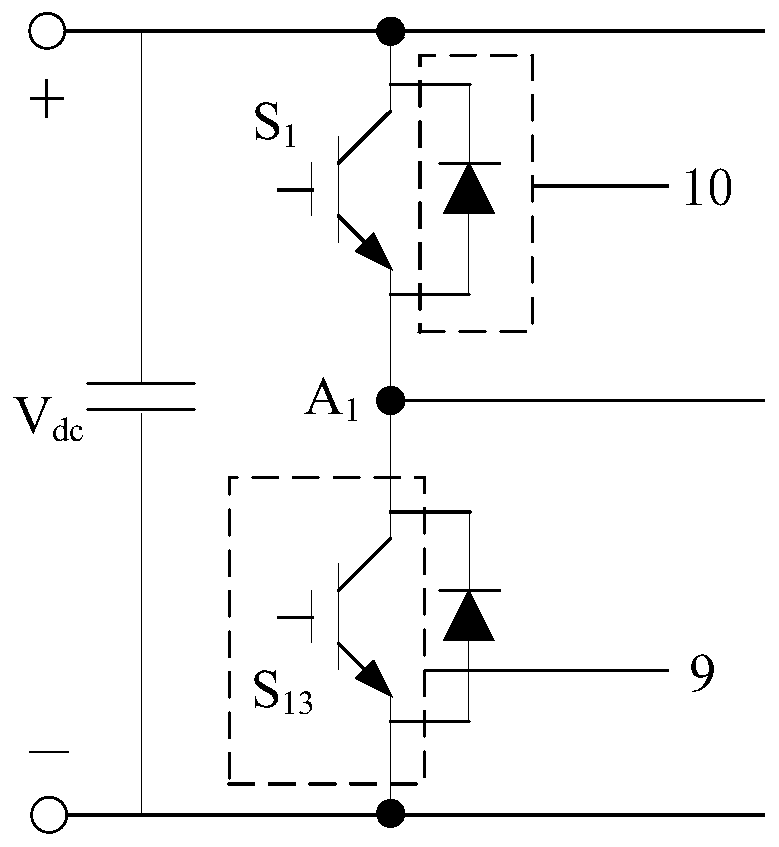

[0031] See Figure 1 to Figure 6, a flexible permanent magnet brushless DC motor control system, including a DC power supply, a filter capacitor 1, a voltage source inverter 3, a permanent magnet brushless DC motor 4 and a controller; the output terminal of the DC power supply is connected to the filter capacitor 1 in parallel; The voltage source inverter 3 is provided with m bridge arms connected to both ends of the filter capacitor 1; each bridge arm is provided with two upper and lower controllable switches 2; the phase number of the armature winding of the permanent magnet brushless DC motor 4 is the same as The number of bridge arms is equal; the first ends of the armature windings 7 of each phase are correspondingly conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com