Grafting machine

A technology of grafting machine and guide rail, which is applied in grafting and other directions, and can solve problems such as complex overall structure, poor bonding between scion and rootstock, and connection errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

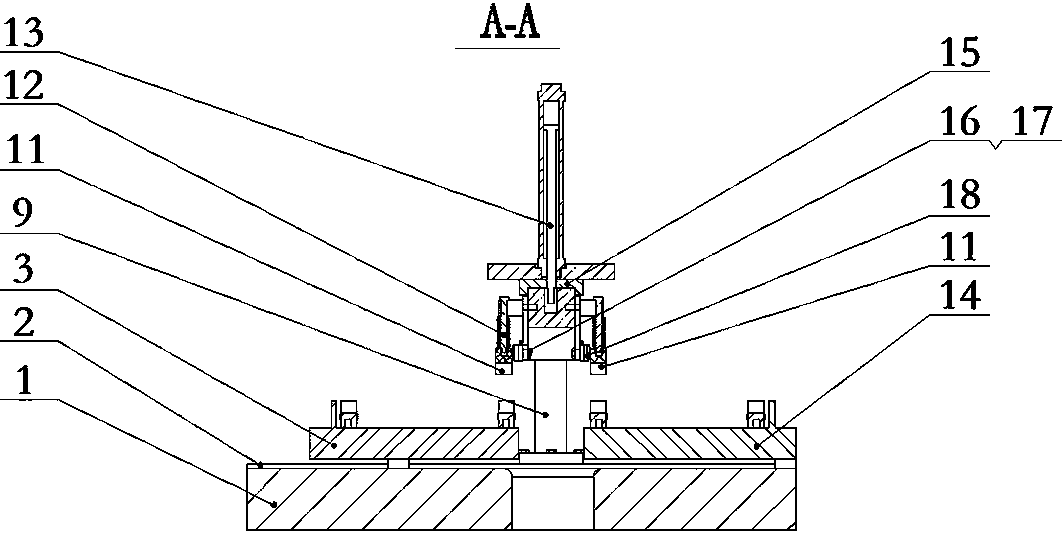

[0036] The traditional grafting machine has many main actions, usually no less than four, many links, many accumulated errors, and many fault points, and the connection between each action and the next action often has a connection error. However, in the embodiment of the present invention, the grafting machine mainly has two actions, that is, vertical cutting and horizontal splicing. Among them, the splicing in the horizontal direction is different from the traditional vertical splicing, and the rootstock Z1 and the scion J1 are opposite in the horizontal direction. The splicing depends on the positioning accuracy in the early stage. The splicing objects do not need to be transferred, and the splicing accuracy is easy to guarantee. . This is the basic purpose of this embodiment.

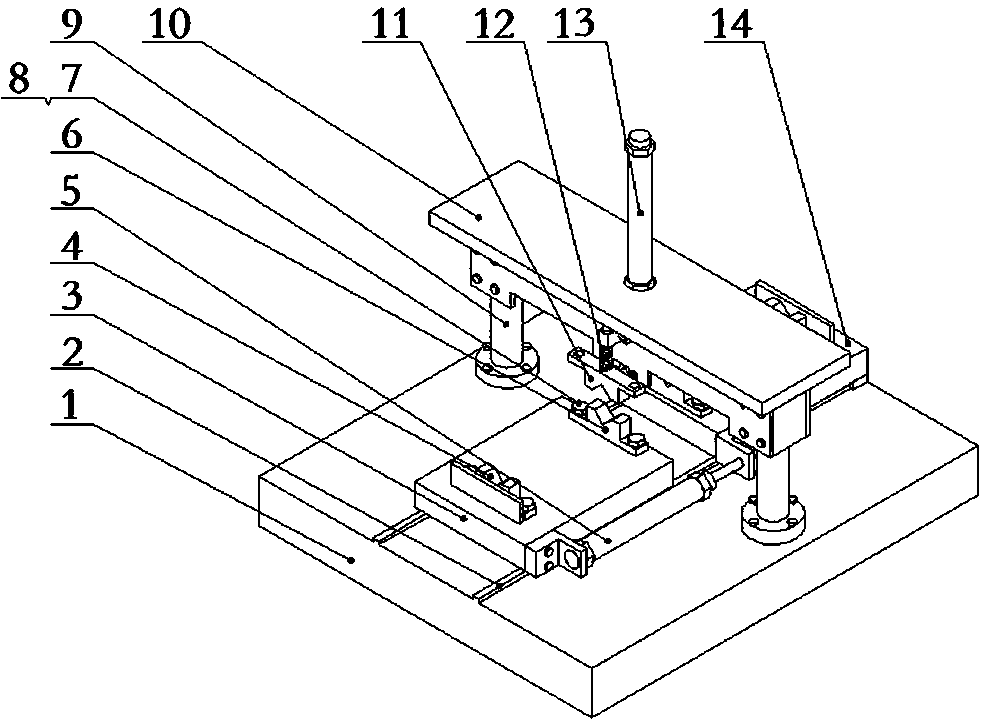

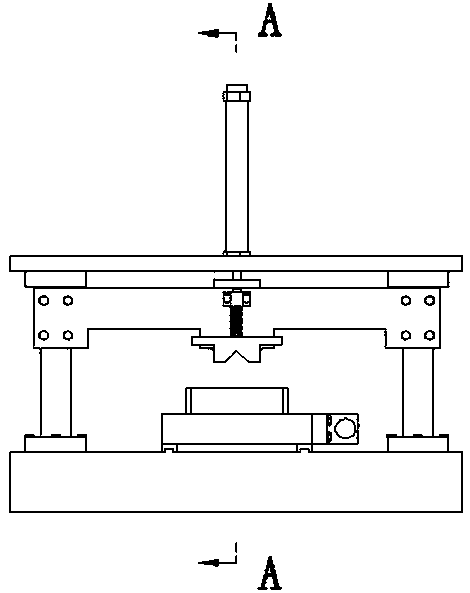

[0037] In order to realize the above-mentioned basic purpose and the understanding and realization of the present invention, in the following embodiments, it is expanded layer by layer Figure 1~3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com