Self-righting sinking-floating net cage capable of realizing long-range monitoring

A remote monitoring and self-righting technology, applied in fish farming, application, climate change adaptation, etc., can solve problems such as cage structural strength, cage heaving, inconvenience, and affecting the growth of aquaculture organisms, so as to reduce risks and difficulties , Guarantee the breeding volume and avoid fish injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

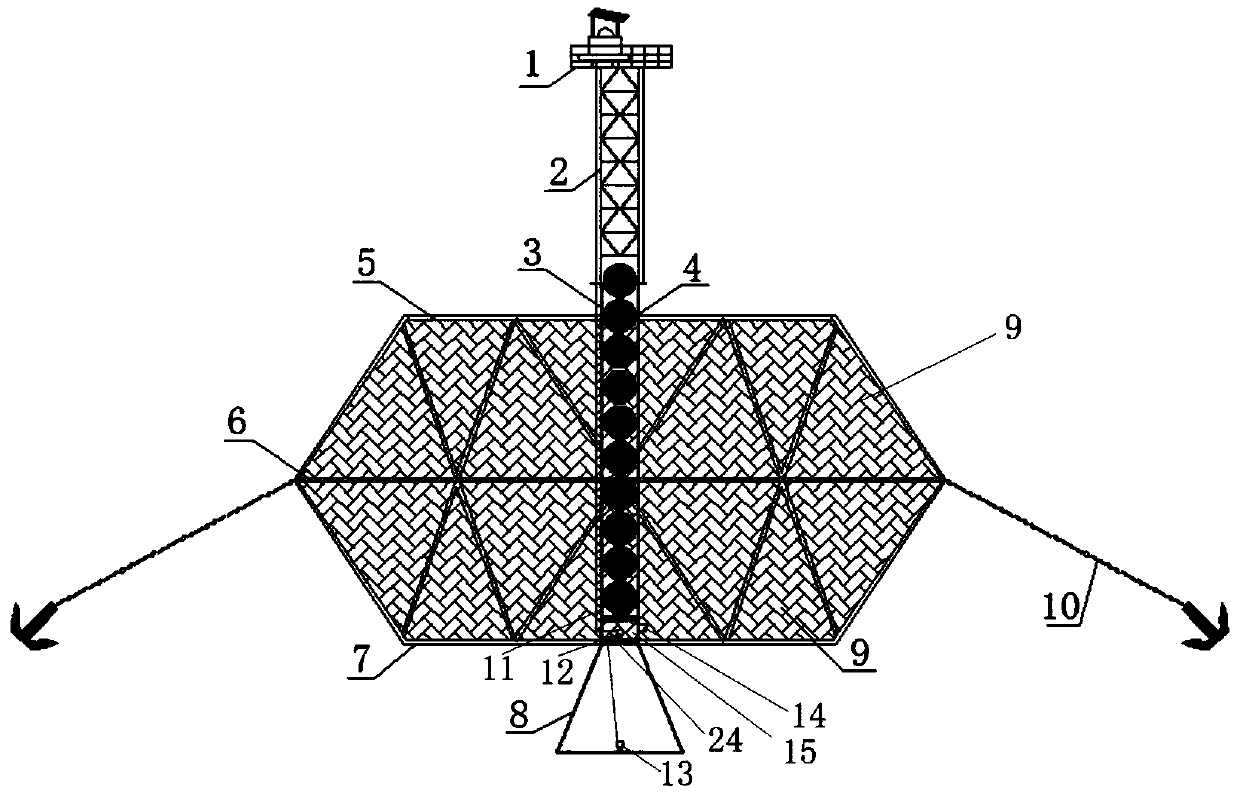

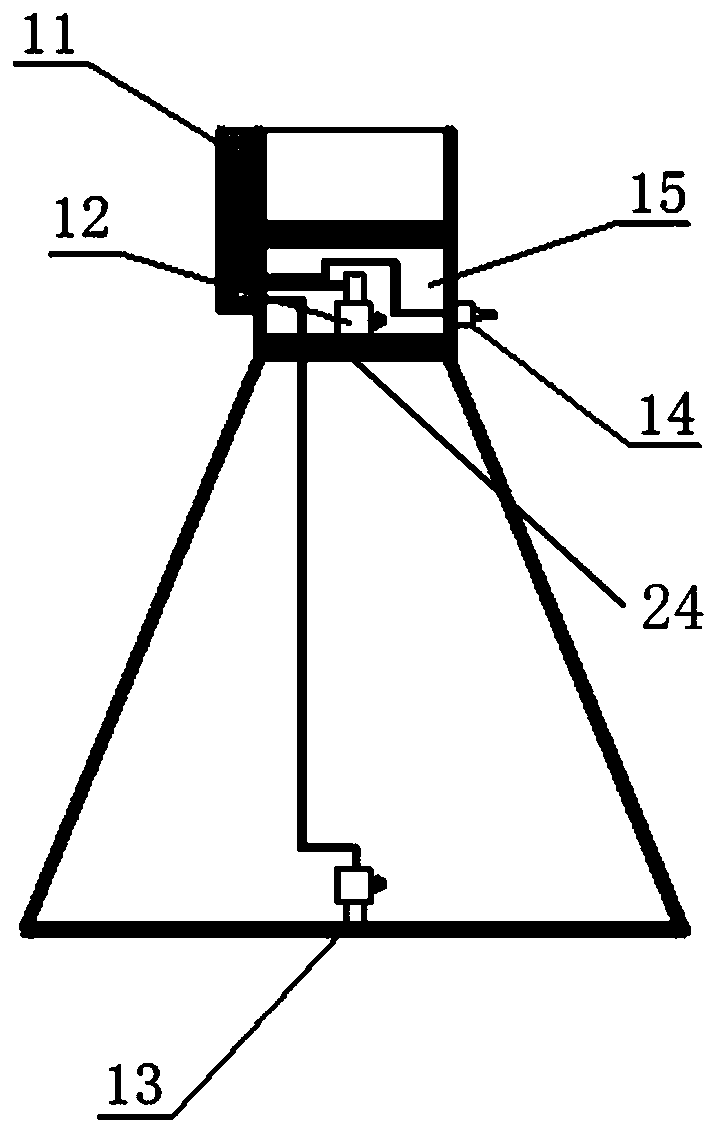

[0027] The net cage sinking process: the net cage is in a floating state under normal breeding conditions. When the sinking operation is required, the control valve at the bottom of the buoyancy adjustment cabin 8 is opened through the valve control system 20 on the operating platform, and the seawater enters the bottom buoyancy adjustment cabin 8 , the gravity of the entire cage system gradually increases, and the cage begins to sink when the amount of water injected reaches a certain level. After the net cage sank to a certain depth, the upper edge of the floating ball storage cabin 3 began to enter water. The floating ball 4 in the floating ball storage cabin 3 is subjected to buoyancy and starts to float up, and floats up to the lower end of the operation platform with the increase of the water inflow, and the floating ball 4 leaves the floating ball storage cabin 3 and floats to the control platform 1, and then starts to be the whole net cage system. Provides buoyancy to ...

Embodiment 2

[0029] Net cage floating process: When the net cage needs to be floated, operate the valve control system 20, open the exhaust valve 12 and water valve 13, and control the air pump 18 on the platform 1 to the buoyancy adjustment cabin 8 through the exhaust valve 12. Inject compressed air into the air, and the air pressure will discharge the water in the buoyancy adjustment cabin 8 through the water valve 13 at the bottom. With the reduction of the water intake in the buoyancy adjustment cabin 8, the gravity of the net cage system decreases. When the buoyancy of the whole system is greater than the gravity, the net cage Start to float. Be positioned at the upper part float 4 to emerge from the water surface gradually this moment, the provided buoyancy reduces gradually, when the net cage floats to predetermined height, stops gas injection drainage, and the net cage system no longer floats. According to actual needs, open water pump 22, the water in the float storage compartment...

Embodiment 3

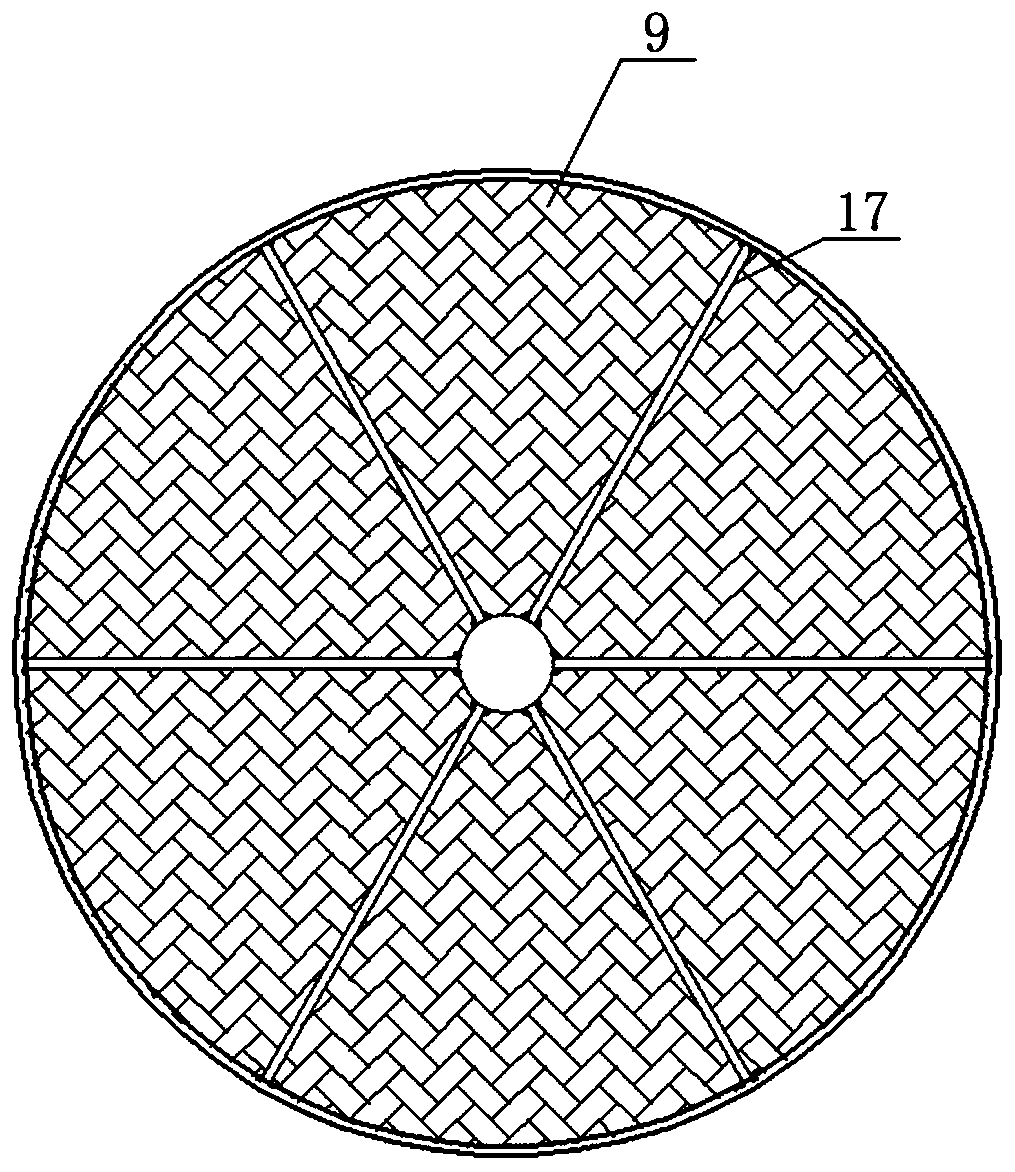

[0031]Net cage changing and net washing process: During the long-term breeding process at sea, operations such as net washing and net changing are required, and the net cage system cannot be washed and changed when the net cage system is in a floating state. At this time, the net clothes 9 need to be floated Operate out of the water. Now according to the requirements of the netting 9, the exhaust valve 12 and the water valve 13 are opened, and the air pump 18 on the control platform 1 is used to inject compressed air into the buoyancy adjustment cabin 8, and the ballast water in the cabin is passed through the bottom by using the air pressure. The drain outlet is discharged, and the cage system begins to float due to the reduction of its own gravity. According to the floating state of the net cage, the amount of ballast water in the buoyancy adjustment cabin 8 and the float storage compartment 3 can be flexibly controlled, so that the net cage can further float up in the float...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com