Engineering inner tube made of nano material and production method thereof

A technology of nanomaterials and production methods, applied in special tires, tire parts, transportation and packaging, etc., can solve problems affecting the bonding strength of inner tube joints and valves, high heat generation in the extrusion process, and heavy weight of engineering inner tubes, etc. , to achieve the effects of forming vulcanization, reducing material costs and increasing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

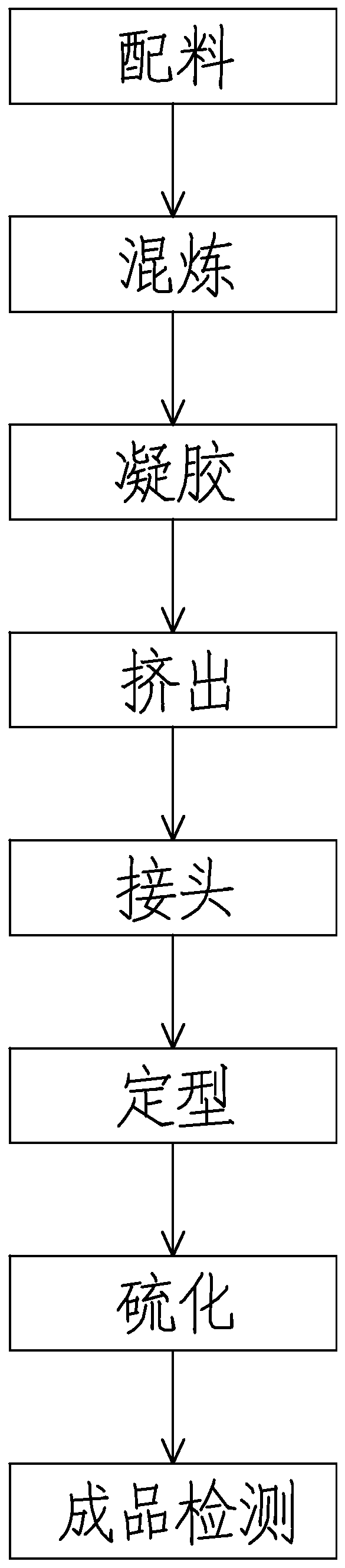

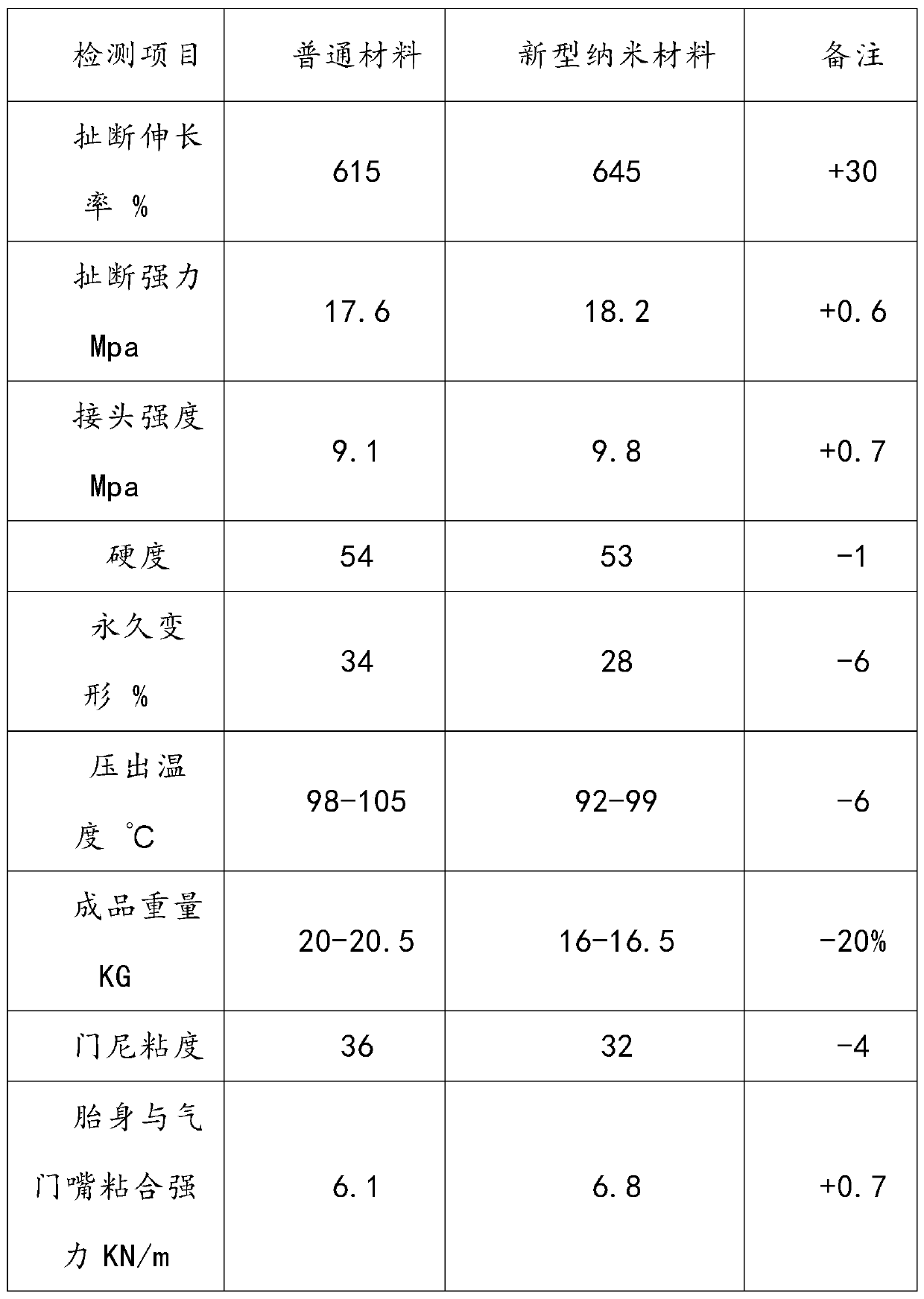

[0034] Such as Figure 1-2 As shown, the inventive point of the present application is that the components of the inner tube are: 70 parts of natural rubber, 30 parts of styrene-butadiene rubber, 3 parts of nano-zinc oxide, 45 parts of nano-calcium carbonate, 15 parts of carbon black, 6 parts of carbon nanotube 1.9 parts of stearic acid, 1.9 parts of vulcanization accelerator, 1.8 parts of accelerator, 3.2 parts of antioxidant, 0.2 part of peptizer, 14 parts of softener, 5 parts of tackifier;

[0035] The manufacturing technological process of described inner tube of a tube is:

[0036] Step 1. Use an internal mixer for mixing, and mix the rubber materials according to the mixing process regulations. The rubber discharge temperature of the first stage of mixing is 145-150 ° C, and the temperature of the second stage of mixing and adding vulcanizing agent is 90- 95°C.

[0037] Step 2. Use an extruder to extrude the compounded rubber into a tire tube according to the construct...

Embodiment 2

[0049] The components of the inner tube are: 80 parts of natural rubber, 20 parts of styrene-butadiene rubber, 3 parts of nano-zinc oxide, 50 parts of nano-calcium carbonate, 15 parts of carbon black, 8 parts of carbon nanotubes, 1.9 parts of stearic acid, vulcanization accelerator 2 parts, accelerator 1.5, anti-aging agent 3.4 parts, peptizer 0.25 parts, softener 12 parts, tackifier 4 parts. Others are the same as in Example 1.

Embodiment 3

[0051] 65 parts of natural rubber, 35 parts of styrene-butadiene rubber, 3.2 parts of nano-zinc oxide, 47 parts of nano-calcium carbonate, 22 parts of carbon black, 5 parts of carbon nanotubes, 1.9 parts of stearic acid, 1.8 parts of vulcanization accelerator, 2.1 parts of accelerator, anti-aging 2.9 parts of agent, 0.2 parts of peptizer, 15 parts of softener, and 6 parts of tackifier. Wherein, the model of the natural rubber is SCR L or SCR 5, the model of styrene-butadiene rubber is SBR 1500 or SBR1502, the carbon black is N220, and the resin is E1102. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com