Electrochemical biosensor for detecting ochratoxin A and preparation method of electrochemical biosensor

A biosensor and ochratoxin technology, applied in biochemical equipment and methods, material electrochemical variables, scientific instruments, etc., can solve the problems of complicated instrument operation and expensive equipment, and achieve good repeatability, low detection limit, and high speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

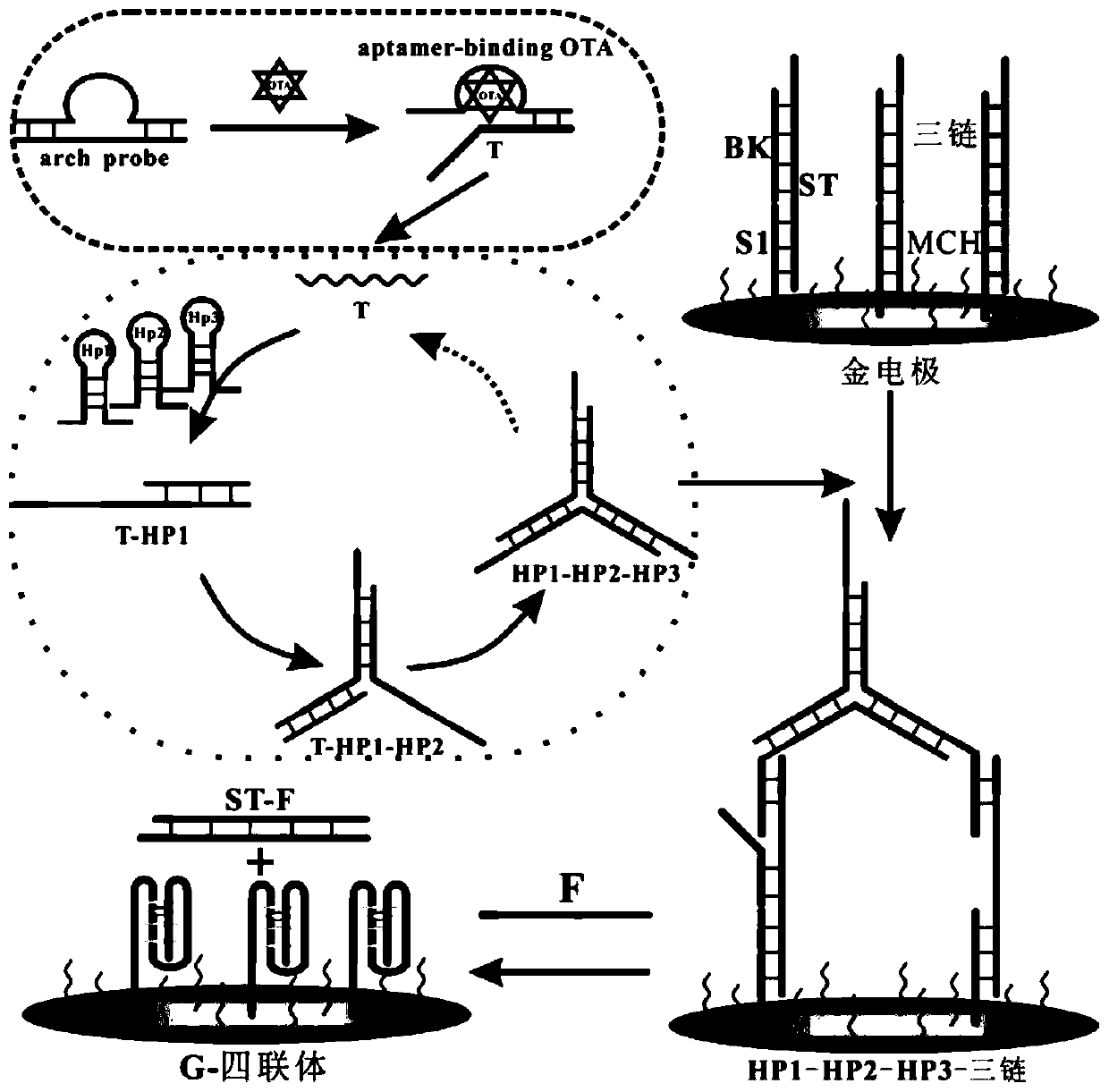

Method used

Image

Examples

Embodiment 1

[0064] A preparation method of the electrochemical biosensor of the present invention, comprising the following steps:

[0065] a. The gold electrode is first polished in 0.3 and 0.05 µm alumina slurry until it becomes a mirror surface, and rinsed repeatedly with PBS and secondary water;

[0066] b. Take 25 µL sterilized water, 10 µL 5×PBS buffer, 5 µL BK chain (2.5 µM), 5 µL S1 chain (2.5 µM), 5 µL ST chain (2.5 µM) in a sterile centrifuge tube, shake After 30 s, put it in a water bath at 95°C for 5 min, and then cool to room temperature;

[0067] c. Add 10 μL of the solution in step b to the surface of the electrode dropwise, incubate at room temperature for 2 h, and wash.

[0068] So far, the modification process of the electrode has come to an end. The following describes the reaction in the homogeneous solution and the main steps in the homogeneous reaction:

[0069] a. Add 5 µL aptamer (10 µM) and 5 µL T (10 µM) into a sterilized centrifuge tube, shake for 30 s, place ...

Embodiment 2

[0077] A preparation method of the electrochemical biosensor of the present invention, comprising the following steps:

[0078] a. The gold electrode is first polished in 0.3 and 0.05 µm alumina slurry until it becomes a mirror surface, and rinsed repeatedly with PBS and secondary water;

[0079] b. Take 25 µL sterilized water, 10 µL 5×PBS buffer, 5 µL BK chain (2.5 µM), 5 µL S1 chain (2.5 µM), 5 µL ST chain (2.5 µM) in a sterile centrifuge tube, shake After 30 s, put it in a water bath at 95°C for 5 min, and then cool to room temperature;

[0080] c. Add 10 μL of the solution in step b to the surface of the electrode dropwise, incubate at room temperature for 2 h, and wash.

[0081] So far, the modification process of the electrode has come to an end. The following describes the reaction in the homogeneous solution and the main steps in the homogeneous reaction:

[0082] a. Add 5 µL aptamer (10 µM) and 5 µL T (10 µM) into a sterilized centrifuge tube, shake for 30 s, place ...

Embodiment 3

[0090] A preparation method of the electrochemical biosensor of the present invention, comprising the following steps:

[0091] a. The gold electrode is first polished in 0.3 and 0.05 µm alumina slurry until it becomes a mirror surface, and rinsed repeatedly with PBS and secondary water;

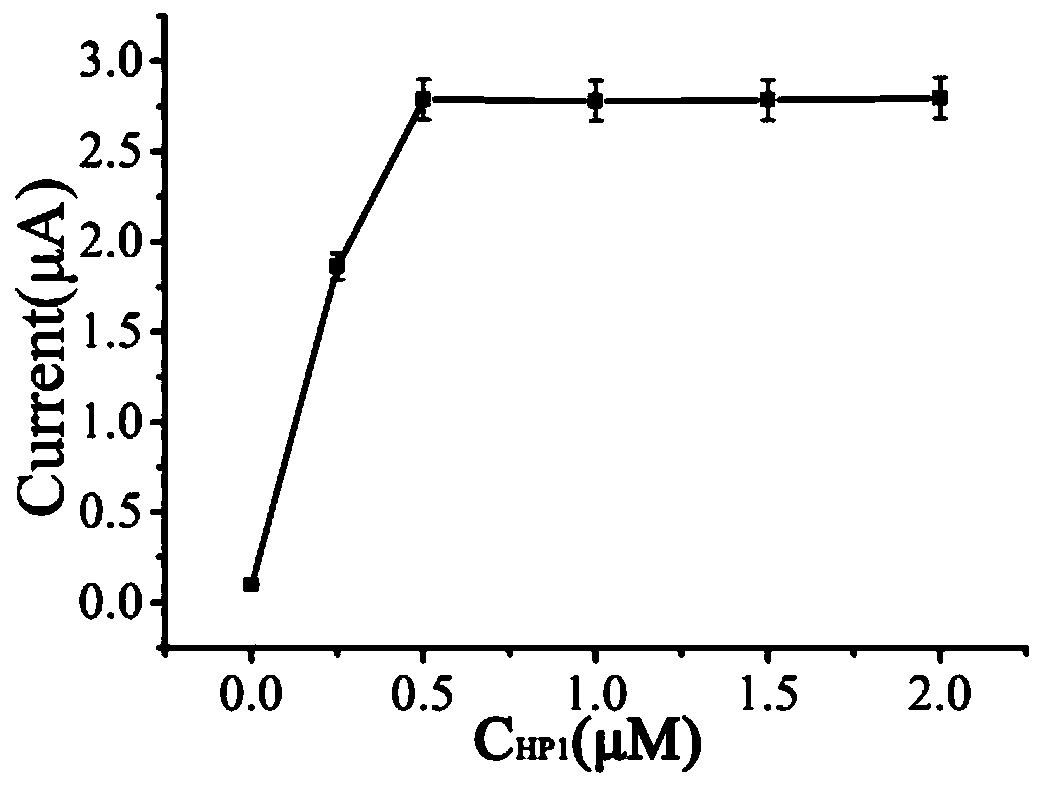

[0092] b. Take 25 µL sterile water, 10 µL 5×PBS buffer, 5 µL BK chain (2.5 µM), 5 µL S1 chain (0.5 µM, 1 µM, 1.5 µM, 2 µM, 2.5 µM, 3 µM, 3.5 µM, 4 µM), 5 µL ST chain (2.5 µM) in a sterilized centrifuge tube, shaken for 30s, put in a 95°C water bath for 5 min, and then cool to room temperature;

[0093] c. Add 10 μL of the solution in step b to the surface of the electrode dropwise, incubate at room temperature for 2 h, and wash.

[0094] So far, the modification process of the electrode has come to an end. The following describes the reaction in the homogeneous solution and the main steps in the homogeneous reaction:

[0095] a. Add 5 µL aptamer (10 µM) and 5 µL T (10 µM) into a sterilized...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com