Rear frame assembly of a wind power generating set

A rear frame and generator technology, applied in the direction of wind motor combination, wind engine, wind power generation, etc., can solve the problems of increasing welding auxiliary man-hours, reducing welding work efficiency, affecting installation effect, etc., and achieves simple structure and simple design scheme , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

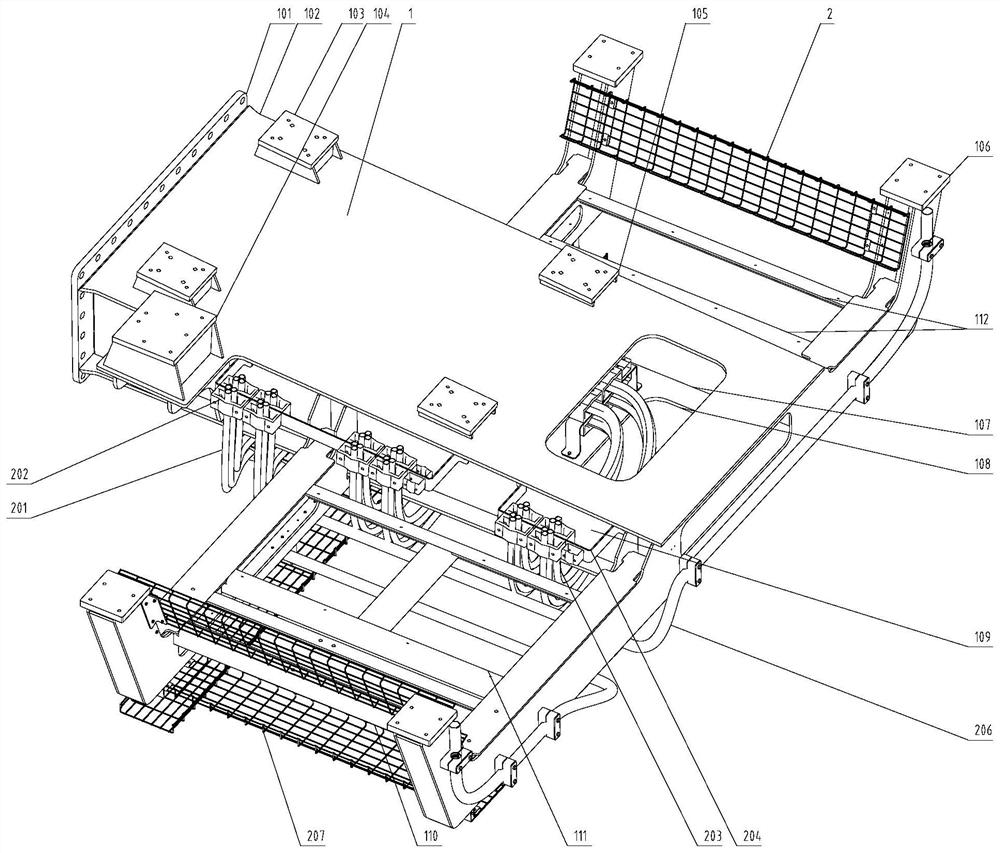

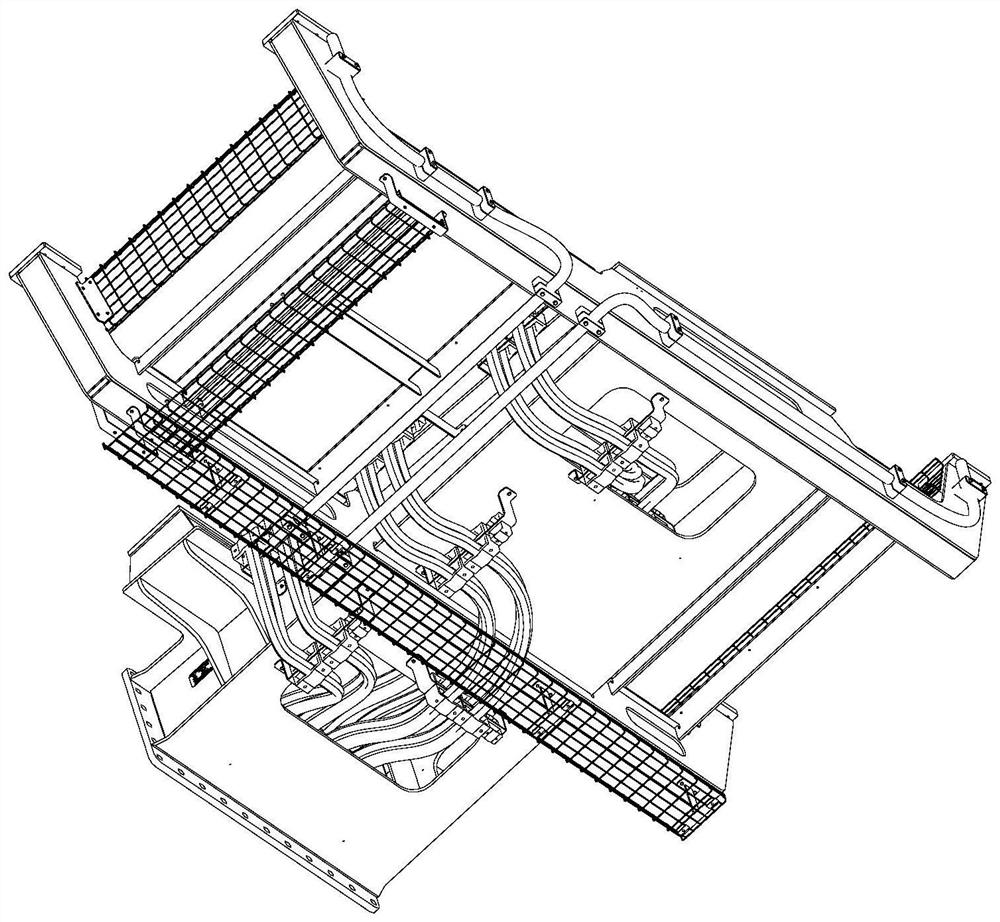

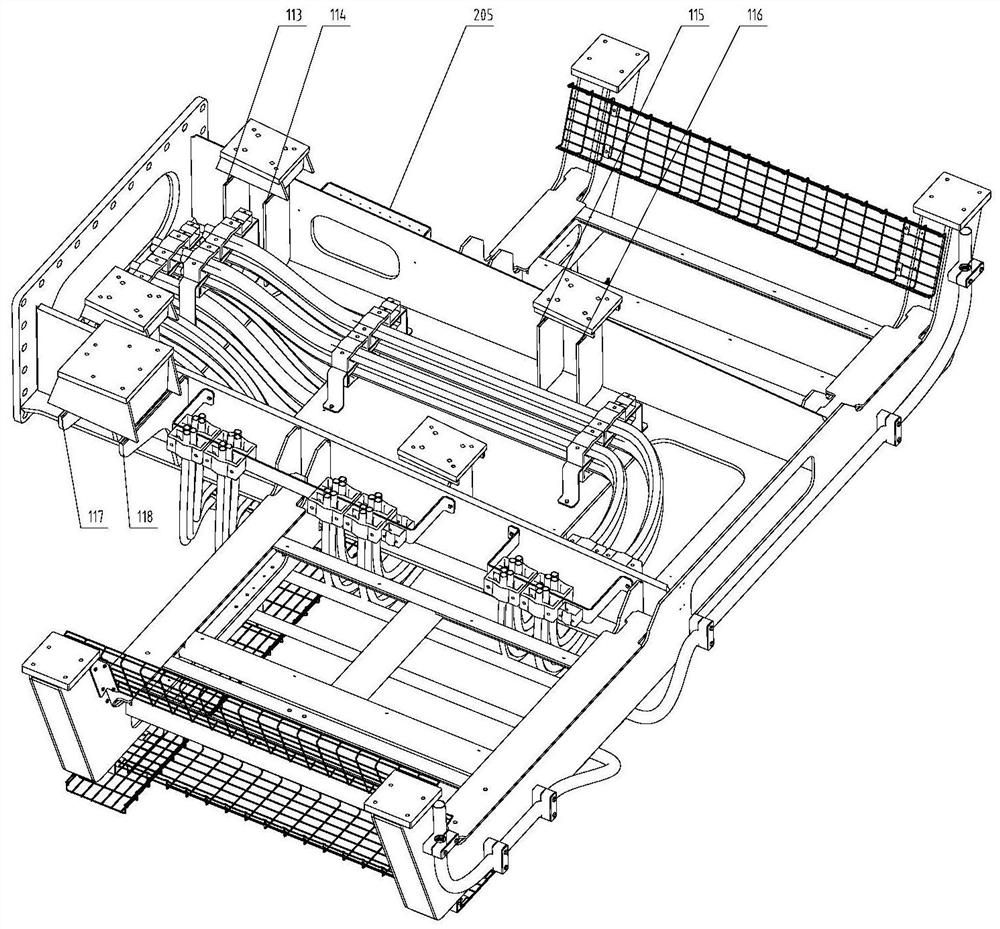

[0043] Such as figure 1 , figure 2 with image 3 As shown, the rear frame assembly of the wind turbine includes two parts, the rear frame welding 1 and the rear frame attachment 2. The rear frame welding 1 is a weldment, including the main frame connecting plate 101, the upper panel 102, Generator front support welding 103, cantilever crane installation support welding 104, generator rear support welding 105, engine room support mounting plate 106, right side plate 107, lower panel 108, left side plate 109, cabin cabinet installation Bracket 110, left side walking channel mounting bracket 111 and right side walking channel mounting bracket 112. The main frame connecting plate 101 is fixed on the main frame for connecting the main frame; the upper panel 102, the lower panel 108, the left side plate 109 and the right side plate 107 are welded with the main frame connecting plate 101; the front support of the generator is welded 103 is welded with the generator rear support 1...

specific Embodiment 2

[0051] Such as figure 1 , figure 2 , image 3 As shown, the rear rack attachment 2 includes the generator rotor outgoing cable 201, the generator rotor outgoing cable mounting frame 202, the generator stator outgoing cable 203, the generator stator outgoing cable mounting frame 204, and the generator auxiliary junction box outgoing cable mounting frame 205, gear box cooling system pipeline 206, mesh cable bridge 207.

[0052] Attachment 2 of the rear frame is equipped with generator rotor outgoing cable 201, rotor cable clamp assembly and generator rotor outgoing cable mounting frame 202. After the outgoing cable is drawn out from the generator, it can be directly fixed on the corresponding mounting frame. Simple and convenient for follow-up wind field maintenance.

[0053] The generator stator outlet cable 203, stator cable clamp assembly and stator outlet cable installation frame 204 are arranged on the rear frame accessory 2. After the outlet cable is drawn out from the...

specific Embodiment 3

[0058] Compared with the specific embodiment 1 of the rear frame assembly of the wind power generator of the present invention, the only difference is: the generator rotor outlet cable 201, the rotor outlet cable mounting frame 202, and the generator stator outlet cable 203 in the above embodiment 1 And the position setting of the stator outlet cable mounting frame 204 can be set on the other side according to the actual situation.

[0059] In summary, the present invention provides a rear frame assembly in a wind power generating set, including rear frame welding and rear frame accessories; the rear frame welding includes a main frame connecting plate, an upper panel, a lower panel, Left side panel, right side panel, welding of front support of generator, welding of rear support of generator, welding of installation support of cantilever crane, installation plate of engine room bracket, installation bracket of engine room cabinet, installation bracket of left aisle, right Sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com