Prosthetic constant-temperature socket and manufacturing method

A receiving cavity and prosthesis technology, applied in the field of prosthetic (prosthetic) receiving cavity, prosthetic (prosthetic (prosthetic) constant temperature receiving cavity, etc., can solve the problems such as the influence of the comfortable prosthetic using function of the receiving cavity, etc., to improve local blood circulation, be beneficial to recovery, Easy to install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to more fully explain the implementation of the present invention, the implementation examples of the present invention are provided, and these implementation examples are only illustrations of the present invention, and do not limit the scope of the present invention.

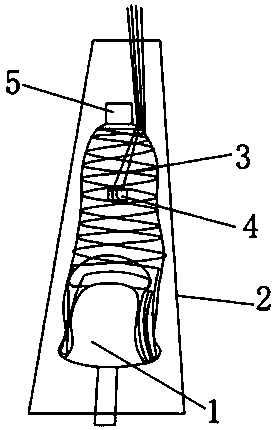

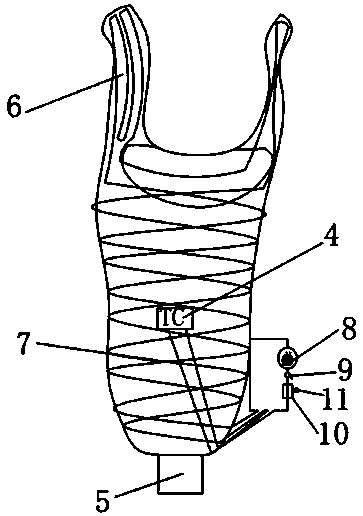

[0021] The present invention is further described in detail in conjunction with the accompanying drawings, and each mark in the accompanying drawings is: 1: plaster positive type; 2. The second PVC film sleeve; 3: high temperature resistant plastic pipe; 4. thermocouple; 5: prosthetic accessories; 6 : socket; 7: heating wire; 8: PCB controller; 9: switch; 10: battery; 11: USB charging interface.

[0022] As shown in the drawings, a prosthetic thermostatic socket, the wall of the socket is embedded with a heating wire 7, and a high temperature resistant plastic tube 3 is embedded in the wall of the socket, and the heating wire is threaded through the high temperature resistant plastic tube. In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com