Positioning and clamping device for circuit board welding fabrication and positioning and clamping method of positioning and clamping device

A positioning and clamping, circuit board technology, applied in auxiliary devices, printed circuits, metal processing, etc., can solve the problems of lack of positioning and clamping equipment, difficult welding process, time-consuming and laborious, etc., to improve the clamping and positioning effect and speed up welding. Process, the effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038]The present invention provides a positioning and clamping device for circuit board welding and a positioning and clamping method of the positioning and clamping device. The two parts are now specifically described:

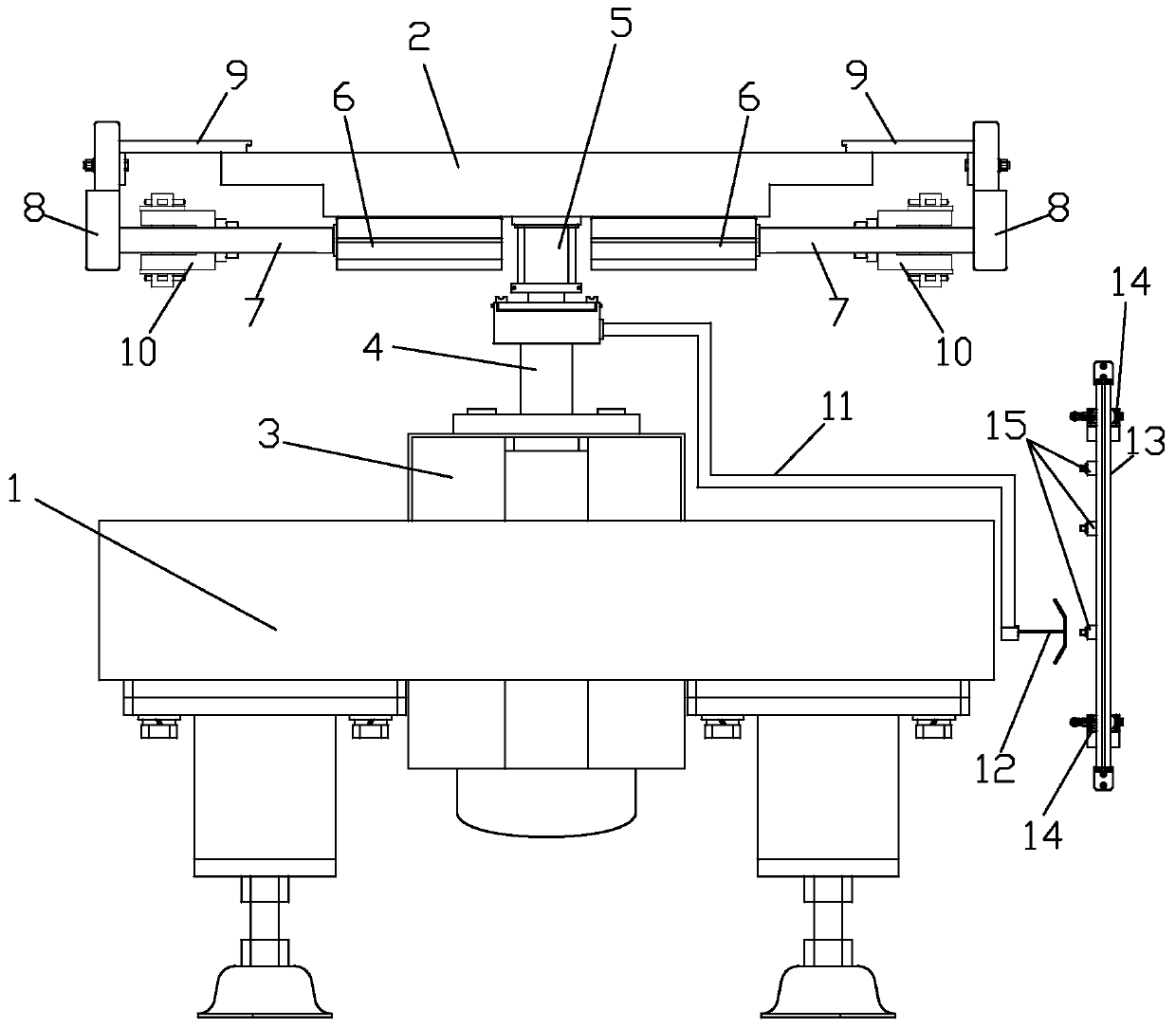

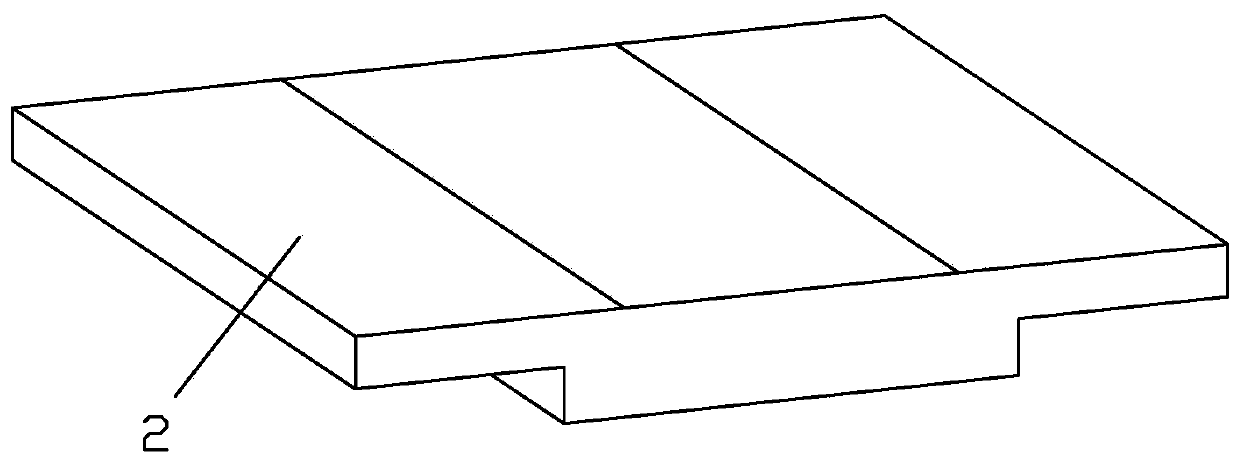

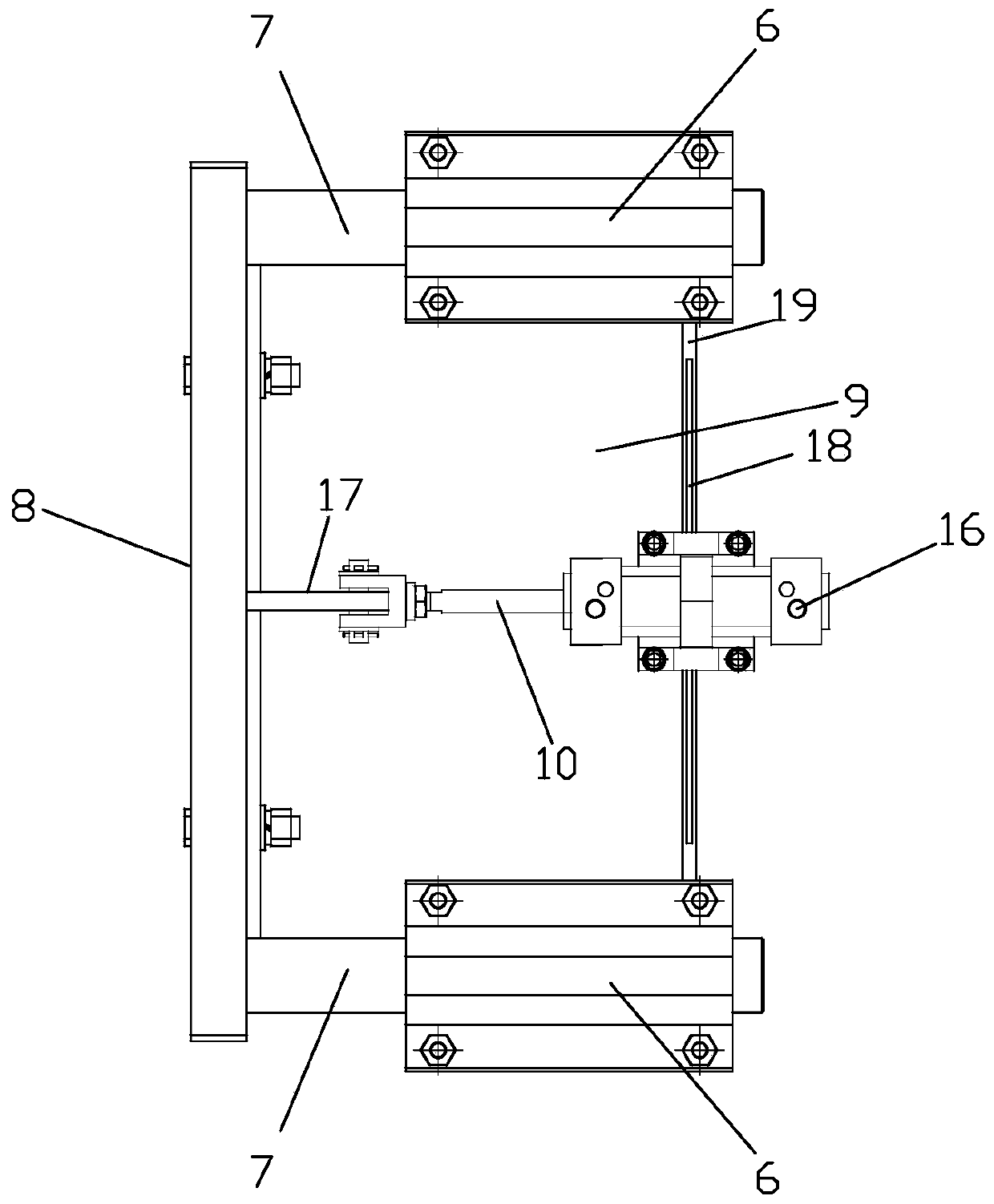

[0039] like Figure 1 to Figure 5 As shown, a positioning and clamping device for circuit board welding processing includes a machine base 1, a table top 2 and a clamping mechanism. The machine base 1 is used to install the table top 2, and the clamping mechanism is installed on the table top 2.

[0040] The machine base 1 is provided with a lifting cylinder 3, and the lifting cylinder 3 is connected to the table base 5 through the second piston rod 4, and then the table base 5 is connected to the table 2. The clamping and positioning device is endowed with a lifting function by the lifting cylinder 3, and the assembly line clamping and positioning operation can be completed in conjunction with the belt conveyor line 21, which significantly improves the weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com